Sealing coating for sheathing layer of bundled cables

A technology for bundling cables and sealing coatings, applied in polyester coatings, coatings, insulation of conductors/cables, etc., can solve the problem of loss of flexibility of cable coating, failure to meet actual use requirements, and impact on equipment delivery time and other problems, to achieve the effect of being suitable for popularization and use, easy construction, and reducing manufacturing and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

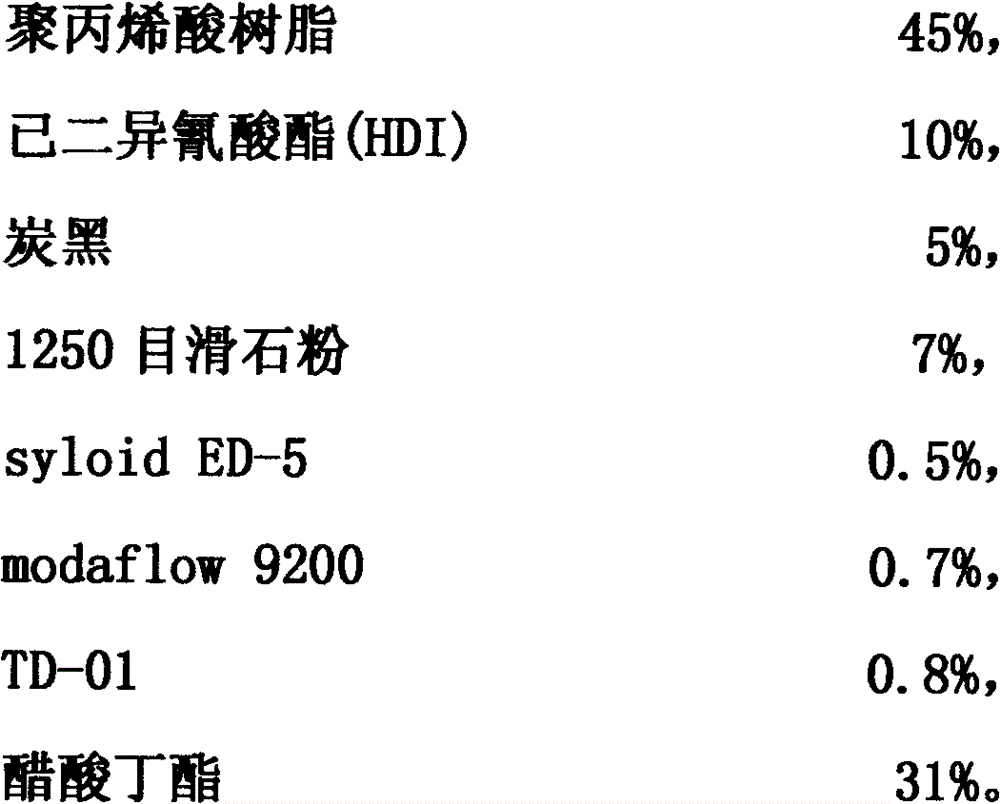

[0021] A kind of sealing paint for sheathing layer of bundled cables is prepared from the following material raw materials in percentage by weight:

[0022]

[0023] Polyacrylic resin and hexamethylene diisocyanate in the above-mentioned formula are coating resin base material, and syloid ED-5 (matting agent), modaflow 9200 (leveling agent), TD-01 (dispersing agent) are auxiliary agents for coating, and butyl acetate is Mixture of solvents for paints.

[0024] The preparation method of this bundled cable covering layer sealing coating is:

[0025] (1), add the resin base material of formula quantity 50%, the mixed solvent of formula quantity 30% and the auxiliary agent of formula quantity into the container and stir evenly;

[0026] (2) Add pigments and fillers according to the amount, and stir while adding materials. After there is no visible dry powder, use a high-speed disperser at 2000 rpm or above for pre-dispersion treatment;

[0027] (3), grind the above-mentioned ...

Embodiment 2

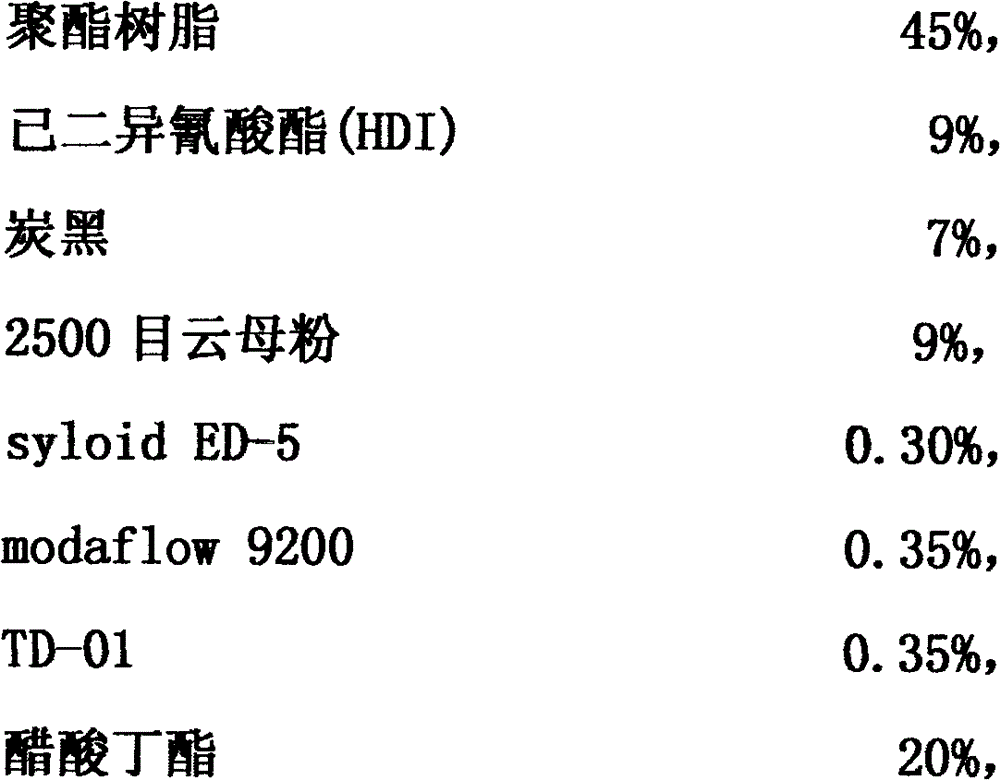

[0031] A kind of sealing paint for sheathing layer of bundled cables is prepared from the following material raw materials in percentage by weight:

[0032]

[0033]

[0034] The polyester resin and hexamethylene diisocyanate in the above formula are paint resin base materials, syloid ED-5, modaflow 9200, and TD-01 are paint additives, and butyl acetate and ethyl acetate are paint mixed solvents.

[0035] The preparation method of the sealing coating for the cladding layer of the bundled cables is the same as that of the first embodiment.

Embodiment 3

[0037] A kind of sealing paint for sheathing layer of bundled cables is prepared from the following material raw materials in percentage by weight:

[0038]

[0039] The polyacrylic acid resin and divinyldiamine in the above formula are coating resin base materials, 1250 mesh talcum powder and 2500 mesh mica powder are the fillers of the coating, syloid ED-5, modaflow 9200, TD-01 are the auxiliary agents of the coating, Xylene is a mixed solvent for paint.

[0040] The preparation method of the sealing coating for the cladding layer of the bundled cables is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com