Preparation method of liquid covering material for agricultural purposes

A covering material and liquid technology, applied in the direction of starch coating, polyester coating, dextran coating, etc., can solve the problems of poor film-forming effect, mechanical properties and mechanical strength performance need to be strengthened, and achieve less residue and better adhesion Strong, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

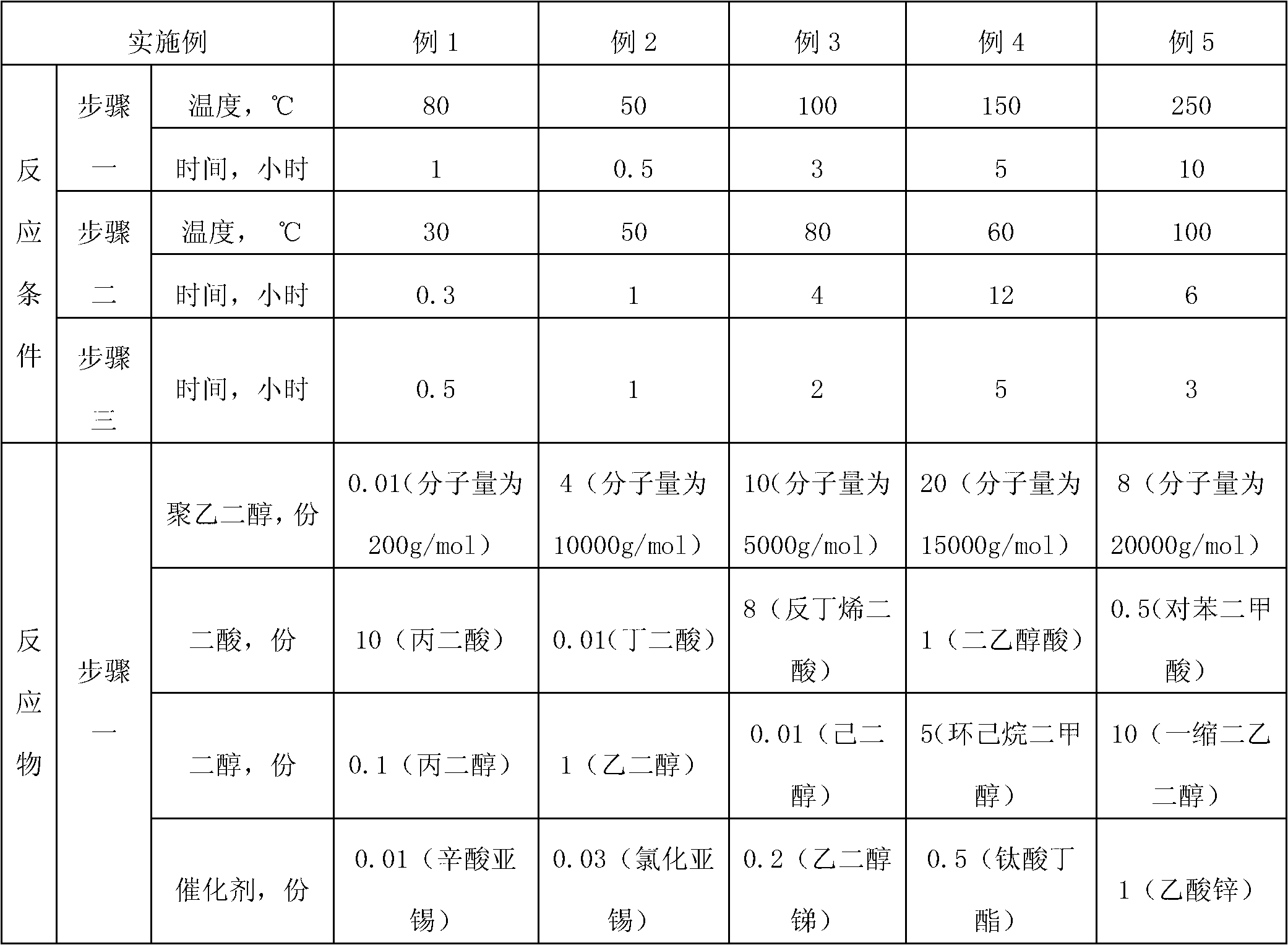

[0016] A kind of preparation method of agricultural liquid covering material of the present invention, comprises the following steps:

[0017] In the first step, 0.01 to 20 parts of polyethylene glycol with a molecular weight of 200 to 20,000 g / mol, 0.01 to 10 parts of diacid, 0.01 to 10 parts of diol, and 0.01 to 1 part of catalyst are mixed at 50 ° C by molar ratio. Stir and react in an oil bath at ~250°C for 0.5 to 10 hours to obtain a complex;

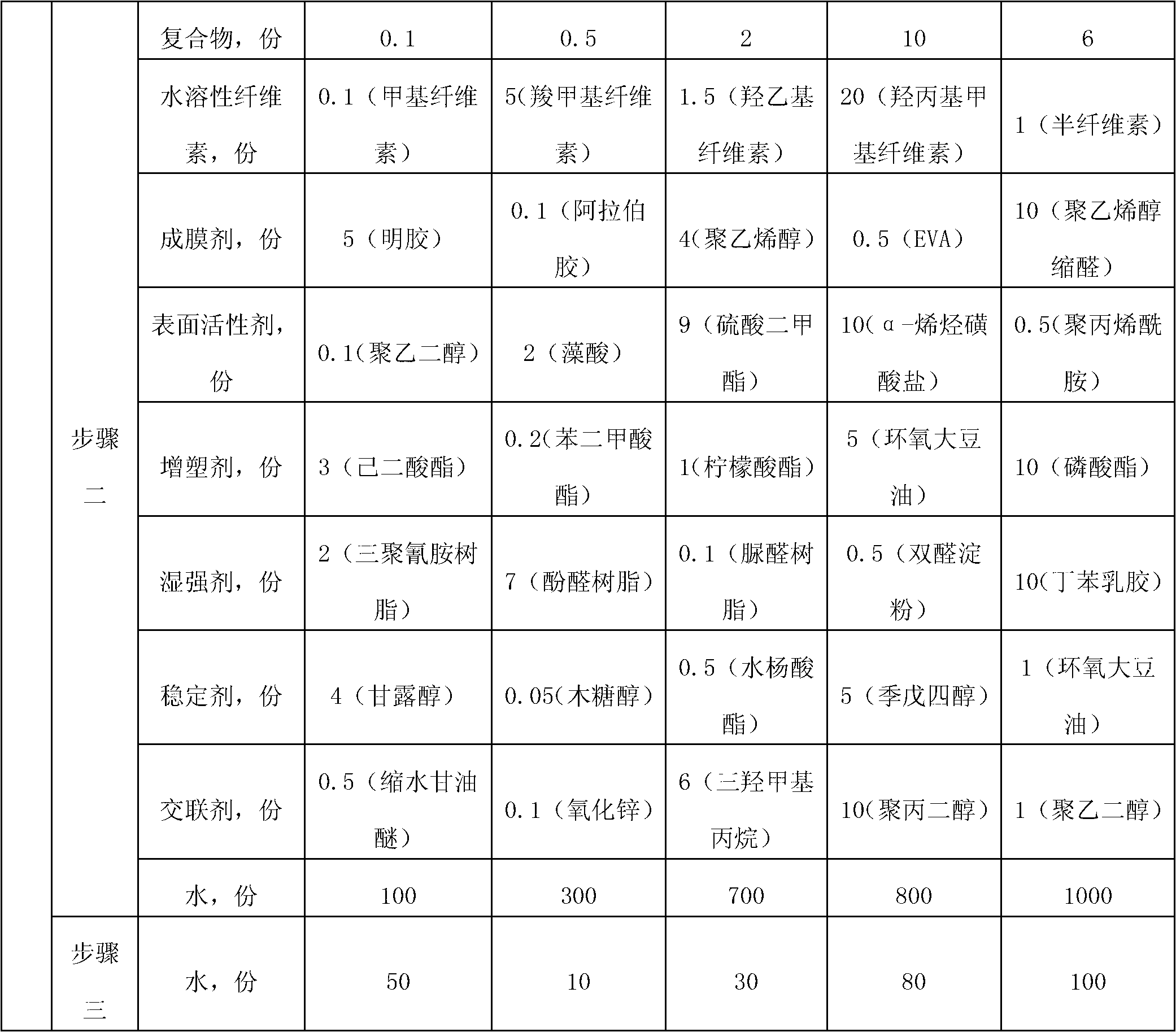

[0018] In the second step, after the compound prepared in the first step is cooled to room temperature, take 0.1-10 parts of the compound in parts by mass, and then add 0.1-20 parts of water-soluble cellulose to the compound, and 0.1-10 parts of the composition Film agent, 0.1-10 parts of surfactant, 0.2-10 parts of plasticizer, 0.1-10 parts of wet strength agent, 0.05-5 parts of stabilizer, 0.1-10 parts of cross-linking agent, 100-1000 parts water, stirred and reacted at 30°C to 100°C for 0.3 to 12 hours;

[0019] In the third s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com