Polymer-dispersed liquid crystal as well as preparation method and application

A technology for dispersing liquid crystals and polymers, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve the problems of poor contrast of polymer dispersed liquid crystals, and achieve the effects of uniform size and distribution, good compatibility, and increased contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

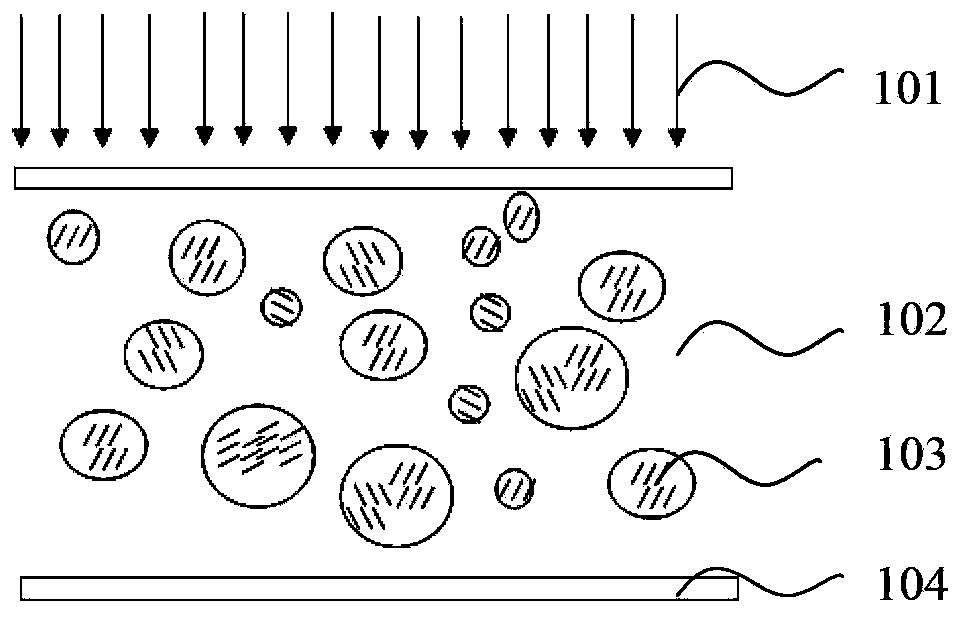

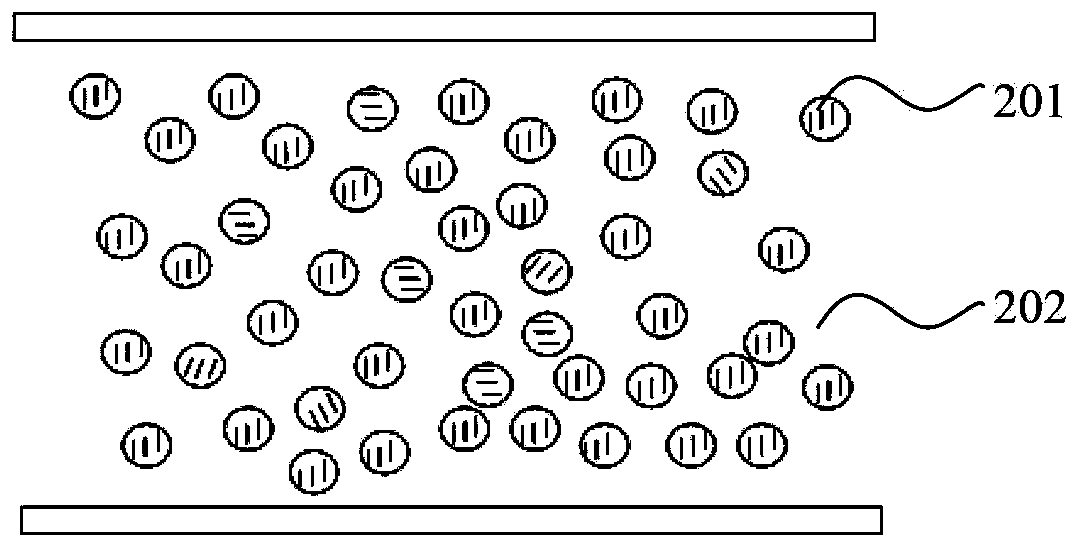

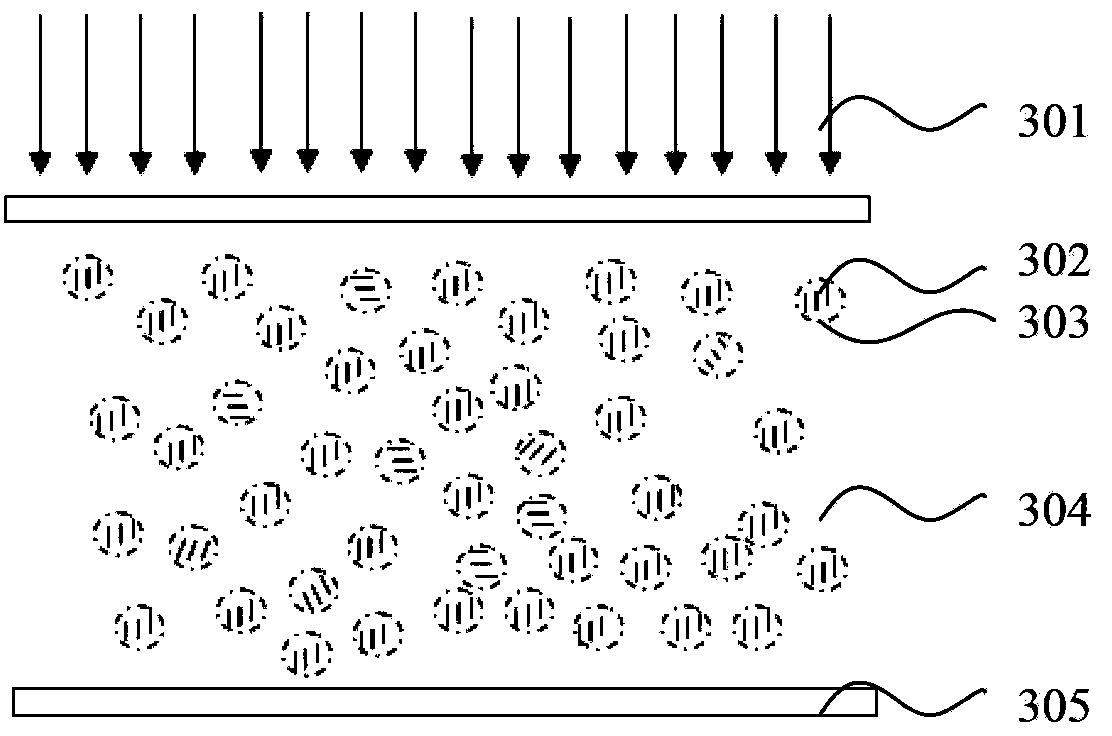

Method used

Image

Examples

Embodiment 1

[0026] (1) Prepare distilled water, sodium polyacrylate and mixed solution, the weight ratio of which is 40:10:50. The mixed liquid is composed of liquid crystal and acrylate, and its weight ratio is 60:40. The degree of polymerization of sodium polyacrylate is 10-100, the liquid crystal is E44, and the acrylate is 2-methyl methacrylate.

[0027] The mixed solution is initially mixed with a magnetic stirrer or an ultrasonic stirrer, and the initial mixing time is 10 minutes to achieve a colloid-like transparent mixing state.

[0028] (2) In a water bath at 80°C or in an infrared environment, use a propeller to stir and disperse, add distilled water to the round bottom flask in turn, add sodium polyacrylate in two batches, increase the stirring speed, and wait until the sodium polyacrylate colloid reaches a stable state Then add the initial mixed liquid, stir thoroughly for 30 minutes, and evaporate part of the water to make the whole system into a viscous liquid mixture. At ...

Embodiment 2

[0033] (1) Prepare distilled water, sodium polyacrylate and mixed solution, the weight ratio of which is 30:20:50. The mixed liquid is composed of liquid crystal and acrylate, and its weight ratio is 60:40. The degree of polymerization of sodium polyacrylate is 10-100, the liquid crystal is E44, and the acrylate is polyurethane acrylate.

[0034] The mixed solution is initially mixed with a magnetic stirrer or an ultrasonic stirrer, and the initial mixing time is 10 minutes to achieve a colloid-like transparent mixing state.

[0035] (2) In a water bath at 80°C or in an infrared environment, use a propeller to stir and disperse, add distilled water to the round bottom flask in turn, add sodium polyacrylate in two batches, increase the stirring speed, and wait until the sodium polyacrylate colloid reaches a stable state Then add the initial mixed liquid, stir thoroughly for 30 minutes, and evaporate part of the water to make the whole system into a viscous liquid mixture. At ...

Embodiment 3

[0039](1) Prepare distilled water, sodium polyacrylate and mixed solution, the weight ratio of which is 30:10:60. The mixed liquid is composed of liquid crystal and acrylate, and its weight ratio is 50:50. The degree of polymerization of sodium polyacrylate is 10-100, the liquid crystal is E44, and the acrylate is polyurethane acrylate.

[0040] The mixed solution is initially mixed with a magnetic stirrer or an ultrasonic stirrer, and the initial mixing time is 10 minutes to achieve a colloid-like transparent mixing state.

[0041] (2) In a water bath at 80°C or in an infrared environment, use a propeller to stir and disperse, add distilled water to the round bottom flask in turn, add sodium polyacrylate in two batches, increase the stirring speed, and wait until the sodium polyacrylate colloid reaches a stable state Then add the initial mixed liquid, stir thoroughly for 30 minutes, and evaporate part of the water to make the whole system into a viscous liquid mixture. At t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com