Gas-solid joint biomass partition speed control pyrolysis system and use method thereof

A biomass pyrolysis and biomass technology, which is applied in the direction of biofuel, direct heating carbonization, special carbonization, etc., can solve the problems of reduced gas utilization efficiency, high cost of dust removal, and high cost of biomass pyrolysis, so as to reduce equipment investment and fan power consumption, simplify the post-processing process, and improve the quality of biotar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

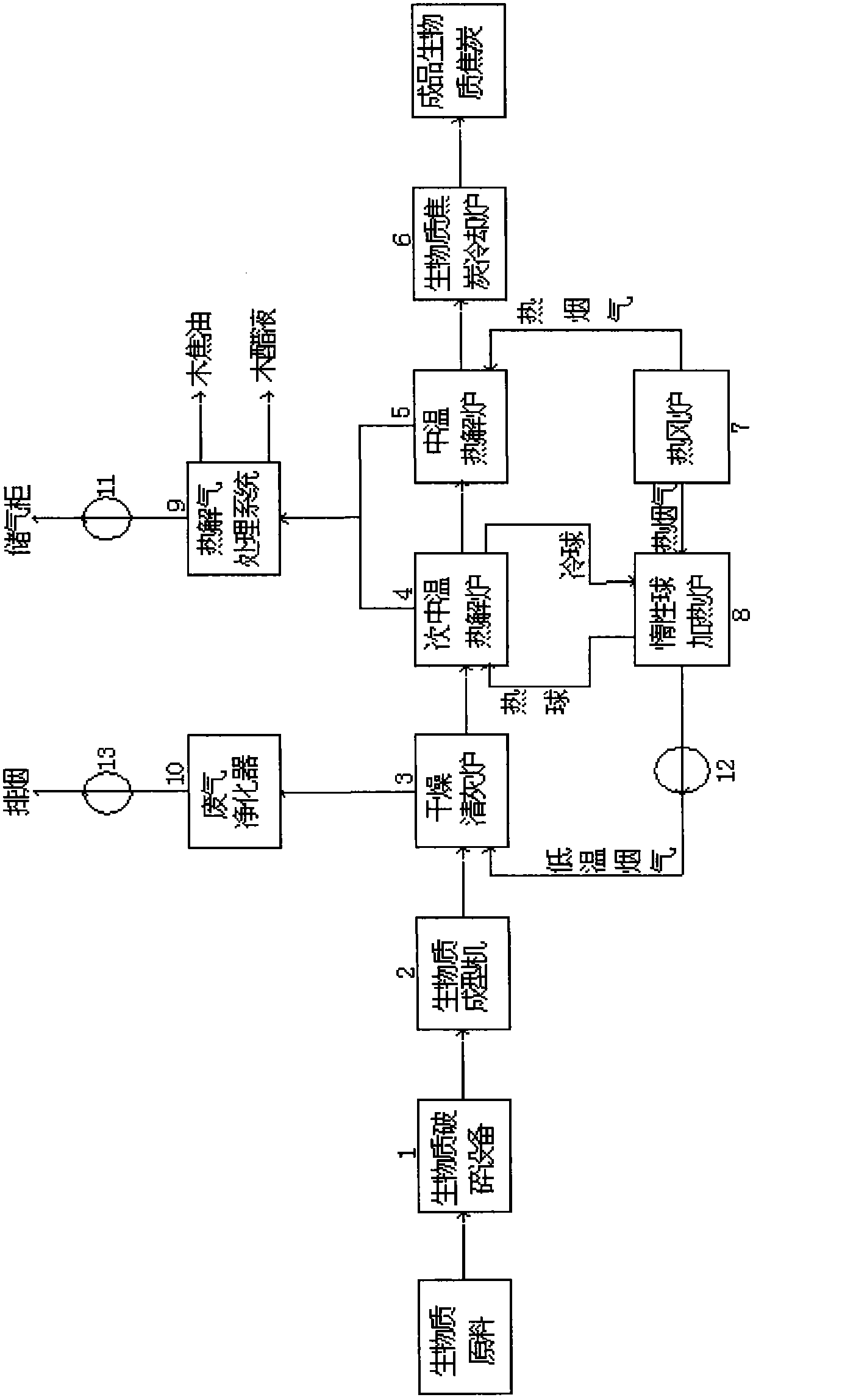

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0040] see figure 1, a flow chart of a gas-solid combined heat-carrying biomass zone-controlled pyrolysis system and method.

[0041] A gas-solid combined biomass partition speed control pyrolysis system, including biomass raw material preparation equipment, biomass pyrolysis equipment, product harvesting equipment and waste gas treatment equipment, biomass pyrolysis equipment includes drying and cleaning furnace 3, secondary The warm pyrolysis furnace 4 and the medium temperature pyrolysis furnace 5 respectively enter the three equipment zones for pyrolysis during pyrolysis. The said sub-medium temperature pyrolysis furnace 3 can use inert solids as the heat carrier. The biomass raw material preparation equipment includes biomass crushing equipment 1 and biomass molding machine 2, and the biomass crushing equipment is a pulverizer or a grinder; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com