Method and device for vacuum electro-osmotic drainage for reinforcing dredged silt soil

A technology of dredging sludge filling and electroosmosis, which is applied in soil protection, construction, infrastructure engineering, etc., can solve problems such as failure to achieve organic integration, inconsistent directions, energy waste, etc., achieve good consolidation and densification, save construction period, shorten the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

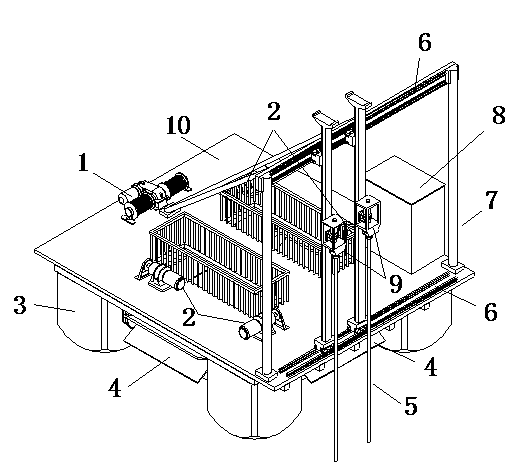

[0032] Such as figure 1 As shown, the plug-in machine used for sludge beating includes hoist (1), engine (2), pile pipe (5), control room (8), vibratory hammer (9), operating platform (10), operating platform (10) Four pontoon tanks (3) are respectively installed in the four corners below, impellers (4) are installed between the pontoon tanks, the impeller blades are connected to the engine (2) through bearings and V-belts, and a gantry is installed on the operating platform (10) Frame (7), pile pipe track (6) is set between gantry (7).

[0033] The vacuum electroosmotic drainage method for reinforcing dredging and filling mud with the above-mentioned plug-in machine includes the following steps:

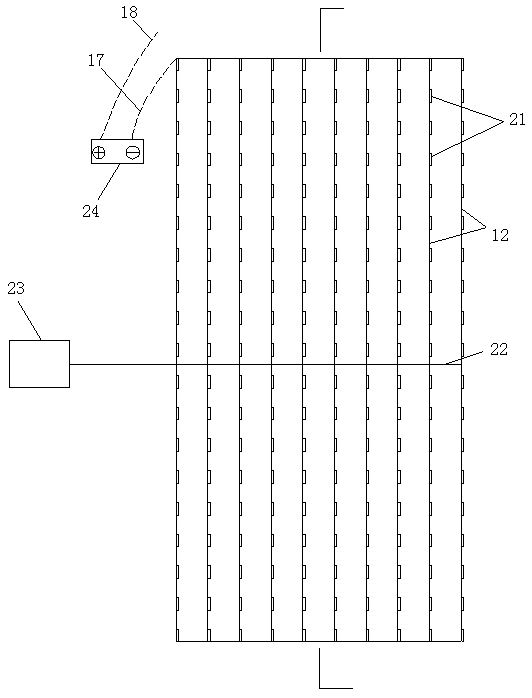

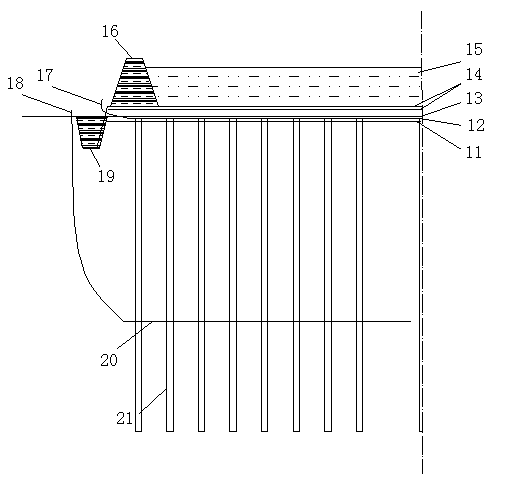

[0034] 1) Make and pre-embed the anode (20). Spread iron rods about 10m long and 24~32mm in diameter at the site design position, and fix them to prevent them from moving during filling. The positive electrode is connected with lead wire (18) and drawn out of the purge filling ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com