Solar selective absorption film system with adjustable color and preparation method thereof

A selective and solar technology, applied in the field of heat absorbing film of solar collectors and light-to-heat conversion materials, can solve the problems of unadjustable appearance color, difficult to control the valence state of compounds, poor light-to-heat conversion performance, etc., to achieve good resistance Erosion resistance, service life improvement, hardness and wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

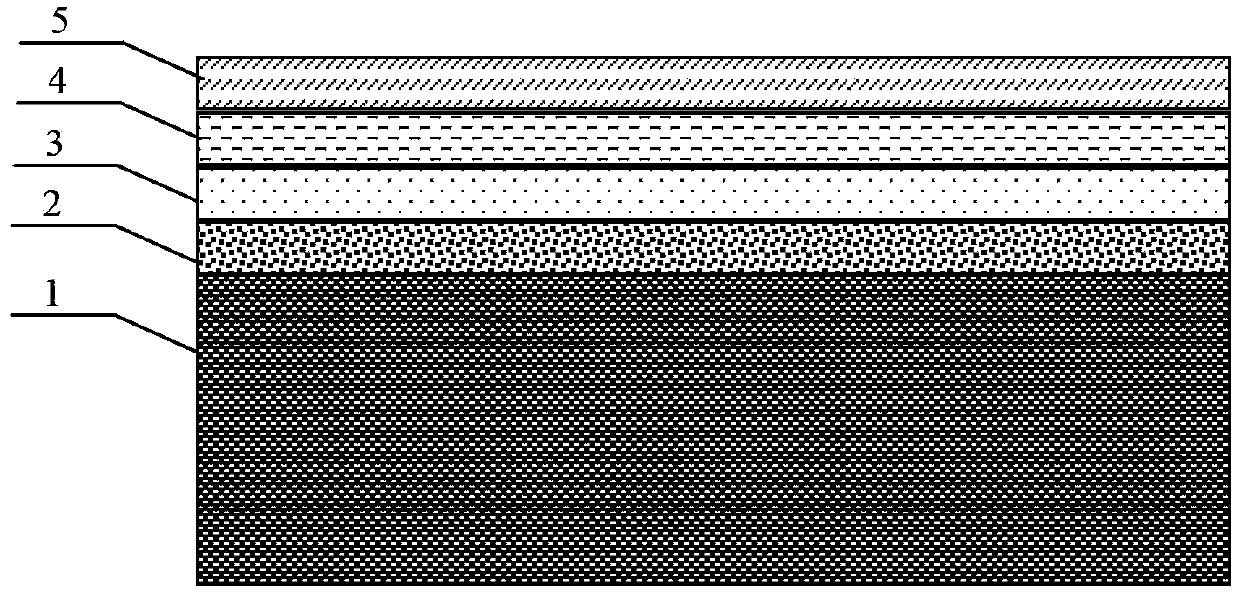

[0048] A dark blue solar selective absorption film system 1 and a preparation method thereof.

[0049] The thickness of each film layer of this absorption film system 1 is composed as follows:

[0050] Cu foil substrate / TiN x o y Thin film (69nm) / Si 3 N 4 Thin film (58nm) / SiO 2 Thin film (54nm).

[0051] Taking the process parameters of the magnetron sputtering equipment used in this embodiment as an example, the preparation method of this absorbing film system is as follows:

[0052] First, using magnetron sputtering method, using Cu foil as the substrate, using TiN sintered according to the preset atomic ratio of Ti, N and O. x o y The ceramic is used as the target material, and a layer of TiN is plated on the Cu film x o y Thin films were grown to a thickness of 69nm by controlling the reactive sputtering time. The atomic ratio of the three elements in the target used in this embodiment is Ti:N:O=1:0.8:1.3, the sputtering power is 1kW, the intermediate frequency f...

Embodiment 2

[0059] A dark green solar selective absorption film system 2 and a preparation method thereof.

[0060] The thickness of each film layer of this absorption film system 2 is composed as follows:

[0061] Ag-coated Cu foil substrate / TiN x o y Thin film (77nm) / TiO 2 Thin film (5nm) / Si 3 N 4 Thin film (63nm) / SiO 2 Thin film (51nm).

[0062] Taking the process parameters of the magnetron sputtering equipment used in this embodiment as an example, the preparation method of this absorbing film system is as follows:

[0063] First, using the magnetron sputtering method, using metal Ag as the target material, a layer of 50nm infrared highly reflective Ag film is coated on the Cu foil substrate;

[0064] Then, the Cu foil substrate coated with Ag film was used as the substrate, the TiN ceramic was used as the target material, Ar gas was used as the sputtering gas, and O gas was introduced as the reaction gas to prepare TiN x o y film. Adjust TiN by adjusting the sputtering pow...

Embodiment 3

[0072] A light yellow solar selective absorption film system 3 and its preparation method.

[0073] The thickness of each film layer of this absorption film system 3 is composed as follows:

[0074] Cu foil substrate / TiN x o y Thin film (97nm) / TiO 2 Thin film (21nm) / Si 3 N 4 Thin film (36nm) / SiO 2 Thin film (49nm).

[0075] Taking the process parameters of the magnetron sputtering equipment used in this embodiment as an example, the preparation method of this absorbing film system is as follows:

[0076] First, using the magnetron sputtering method, using Cu foil as the substrate, metal Ti as the target material, Ar gas as the sputtering gas, and N gas and O gas as the reaction gas to prepare TiN with gradually changing composition. x o y film. Preparation of TiN with gradually changing composition by controlling the flow ratio or pressure ratio of Ar gas, N gas and O gas over time x o y Thin film, by controlling the reactive sputtering time to grow the film thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com