Visual process control system configuration simulation method

A process control system, configuration simulation technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the lack of pure software process control simulation experiment platform, no control principle visualization function, and long secondary development time and other problems, to achieve the effect of reducing the workload of research and development, convenient operation and rich variety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

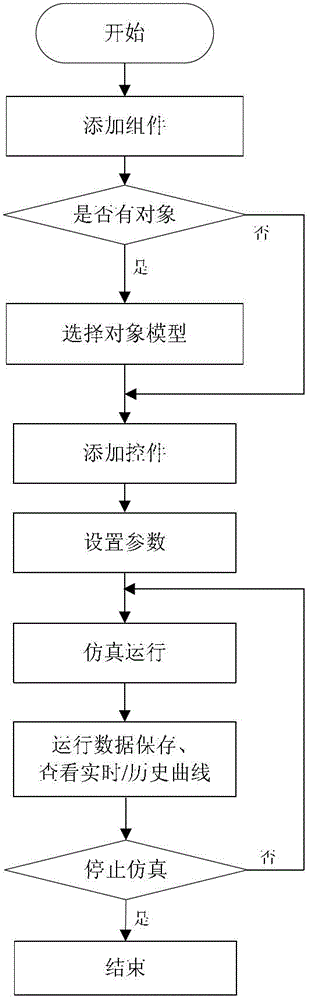

[0050] A flow chart of a visual process control system configuration simulation method based on VC++ and Matlab mixed programming is shown in figure 1 ; Take the single-loop water tank liquid level fuzzy control system as an example, use this system to control the water tank liquid level, and realize the simulation operation using this control system simulation.

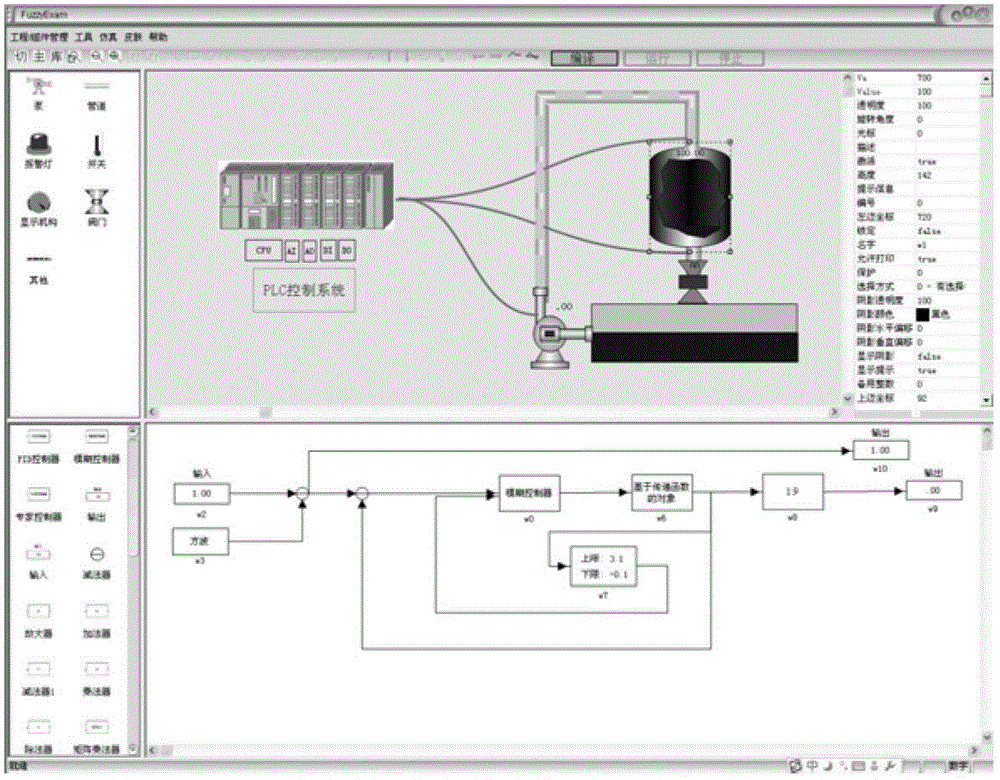

[0051] First, in the figure 2 In the new project configuration diagram, the virtual object water tank w6 is established, which is a second-order system, and the transfer function of the second-order system is:

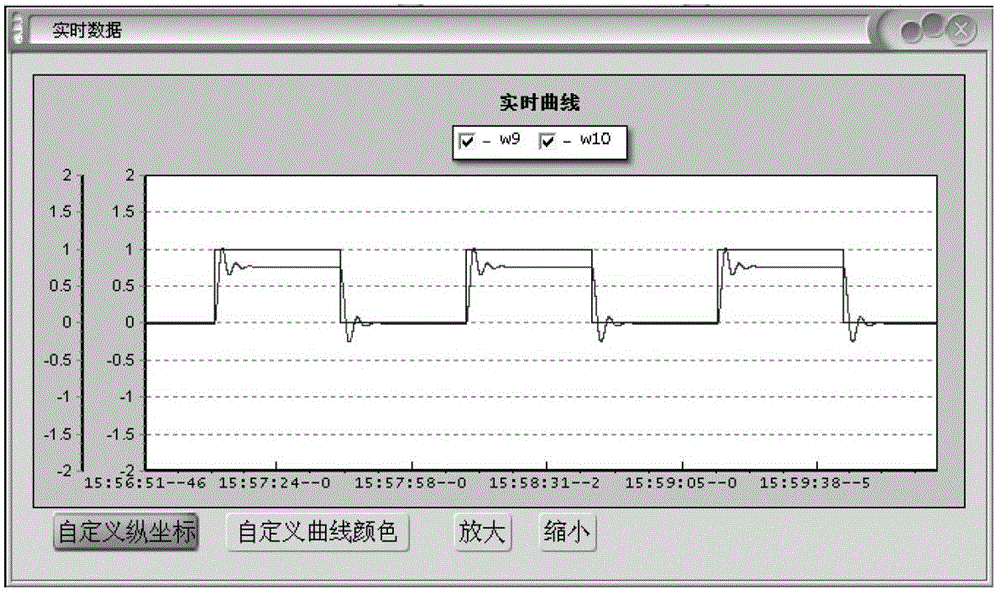

[0052] Secondly, in the schematic diagram, build the system control block diagram, the input signal is a square wave, the period is 62 seconds; the output is the corresponding tracking square wave, and the controller is a fuzzy controller.

[0053] The fuzzy controller is the core of the control system. It has two inputs and one output. The two inputs are the error and the actual output of the system; one...

Embodiment 2

[0060] Taking the single-loop water tank liquid level PID control system as an example, using this system to control the liquid level of the actual water tank object shows that the system can also be used for the control simulation of the actual system.

[0061] First, according to Figure 4 Connect the tank level control system hardware. The shape of the actual water tank is an inverted conical truncated top and a cylindrical bottom, R=275mm, r=50mm, H 1 =500mm,H 2 =155mm, the frequency converter at the water inlet is the actuator, and the opening of the solenoid valve at the water outlet is fixed at 25.

[0062] Secondly, create a new project configuration diagram according to the hardware connection system, such as Figure 5 .

[0063] Again, in the schematic diagram, build the system control block diagram, the initial input setting w3 = 400, the controller w2 selects the PID controller, the PID controller parameters P = 20, I = 1, D = 1, after the limit of the controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com