Production method of aerospace radiation-resistant cable

A radiation-resistant cable, aerospace technology, used in cable/conductor manufacturing, insulated cables, cables, etc., can solve the problem of high strength, achieve high voltage resistance, excellent radiation resistance, excellent electrical insulation and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

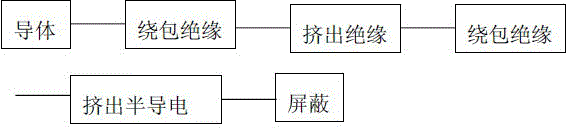

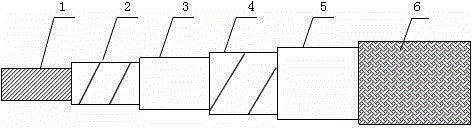

[0026] AWG18 wire, twisted with 19 pieces of 0.26mm nickel-plated round copper wires, through a compression mold to obtain (1.23±0.03)mm stranded conductors; use a concentric wrapping machine to wrap 3 layers of 0.0254mm thick PI tape, and cover The rate is between 67%%; after wrapping, use an extruder to extrude pure polyetheretherketone (PEEK) material with a thickness of 0.30mm to obtain a PEEK layer with high crystallinity, so that the temperature resistance level of PEEK can reach 260°C; then use a wrapping machine to wrap 3 layers of PI tape with a thickness of 0.0254mm, the wrapping rate is between 67% and 70%, and finally form a composite insulating layer of PI+PEEK+PI; the volume resistivity is 10 3 PEEK semi-conductive material between Ω·cm, extrude PEEK semi-conductive material with a thickness of 0.20mm with an extruder to form a semi-conductive layer, so that the semi-conductive layer has an anti-static effect; finally use 0.15mm nickel-plated round copper wire Br...

Embodiment 2

[0028] AWG18 wire, twisted with 19 pieces of 0.26mm nickel-plated round copper wires, through a compression mold to obtain (1.23±0.03)mm stranded conductors; use a concentric wrapping machine to wrap 3 layers of 0.0254mm thick PI tape, and cover The rate is between 67% and 70%; after wrapping, extrude pure polyether ether ketone (PEEK) material with a thickness of 0.30mm by extruder to obtain a PEEK layer with high crystallinity, so that the temperature resistance level of PEEK It can reach 260°C; then use a wrapping machine to wrap 3 layers of PI tape with a thickness of 0.0254mm, the wrapping rate is between 70%, and finally form a composite insulating layer of PI+PEEK+PI; the volume resistivity is 10 7 PEEK semi-conductive material between Ω·cm, extrude PEEK semi-conductive material with a thickness of 0.20mm with an extruder to form a semi-conductive layer, so that the semi-conductive layer has an anti-static effect; finally use 0.15mm nickel-plated round copper wire Braid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com