A preparation method of zno spherical hollow shell structure nanoparticle array

A technology of nanoparticle arrays and empty shells, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., and can solve the problems of low solar photoelectric conversion efficiency and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

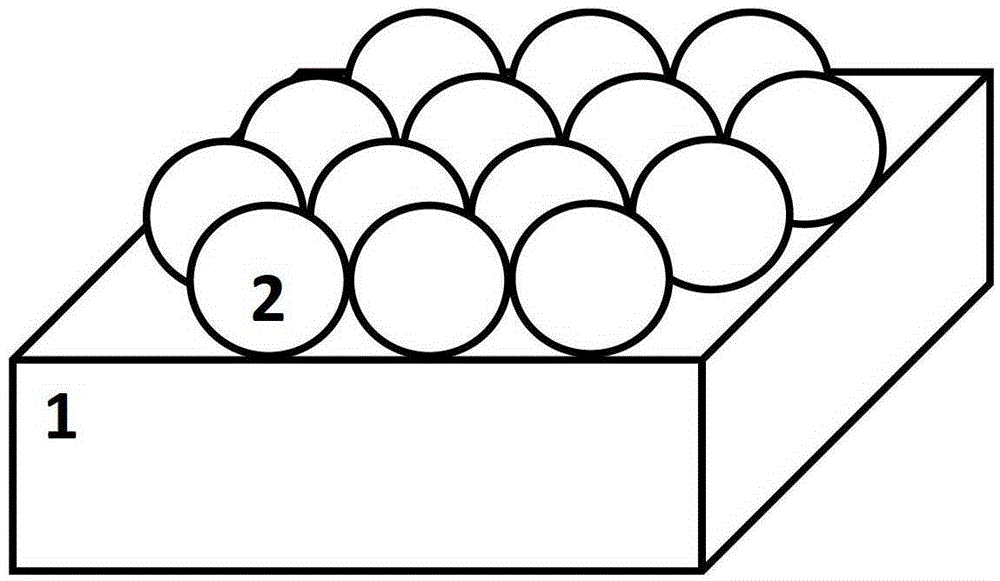

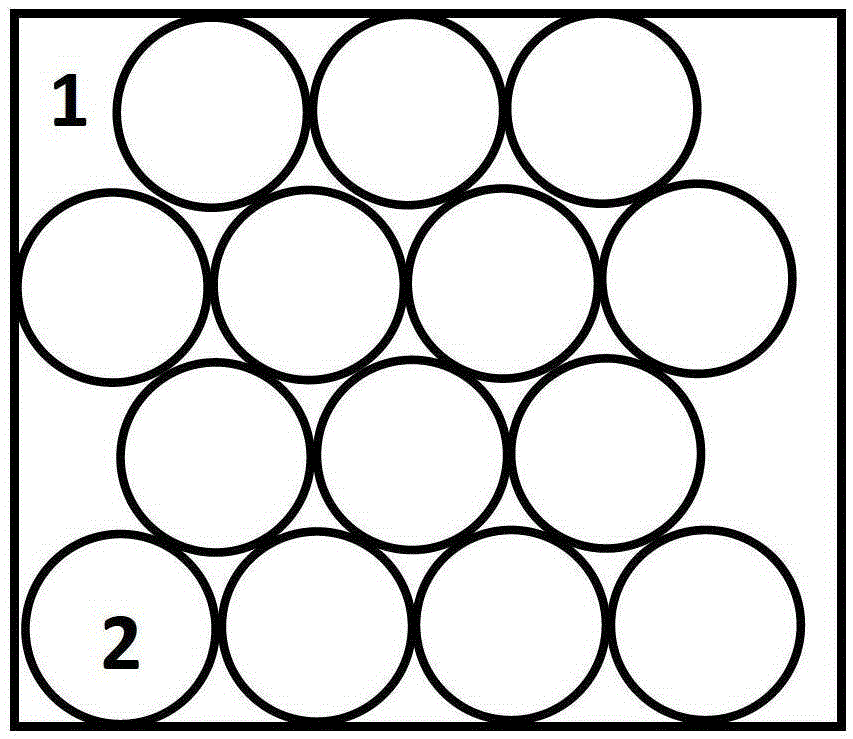

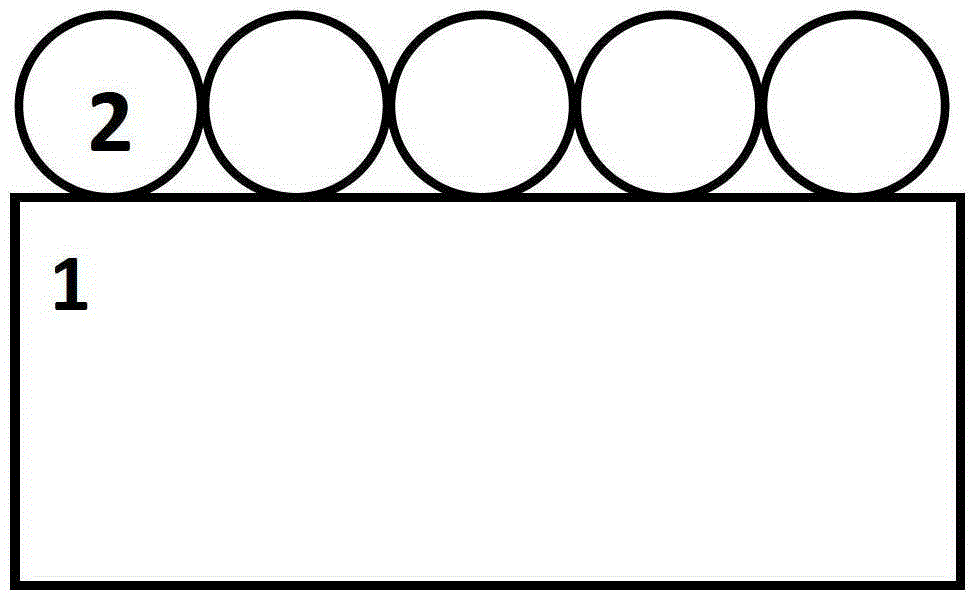

Image

Examples

Embodiment

[0057] First, the cleaned silicon thin film solar cell substrate (size: 10mm×10mm cell) is activated for 6 minutes under the RIE system with a power of 80W, and then self-assembled single-layer PS nanospheres (500nm in diameter) are rotated at a low speed Control at 500rpm, spin coating time 10s, high speed 2500rpm, spin coating time 40s. Then put the silicon thin-film solar cell substrate with the single-layer PS nanosphere as the template into the RIE system with a power of 80W to etch for 60s, O 2 The flow rate is 2.0L / min. In the next step, put the above-mentioned treated sample into the magnetron sputtering deposition equipment to sputter the ZnO film. During sputtering, the RF power is 75W, and the ratio of argon and oxygen is 1:1; the substrate is rotated without heating, The pressure is 1 Pa, and the sputtering time is controlled at 24 minutes, so as to ensure that the thickness of the sputtered ZnO film is 50 nm. Finally, the samples of the above sputtered ZnO films...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com