Preparation method and light emitting diode (LED) structure of indium gallium nitride (InGaN) base multiple quantum well structure

A multi-quantum well structure and quantum well technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low luminous efficiency and low internal quantum efficiency, and achieve the effect of improving the probability of radiation recombination and increasing the internal quantum efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

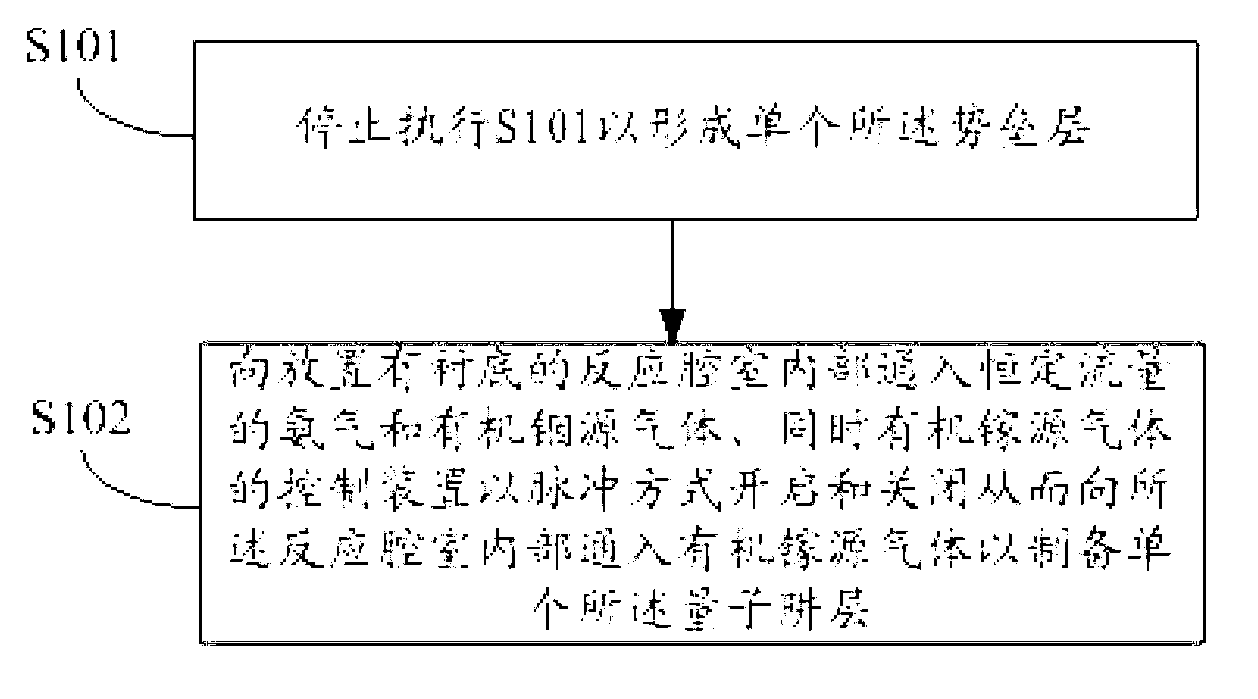

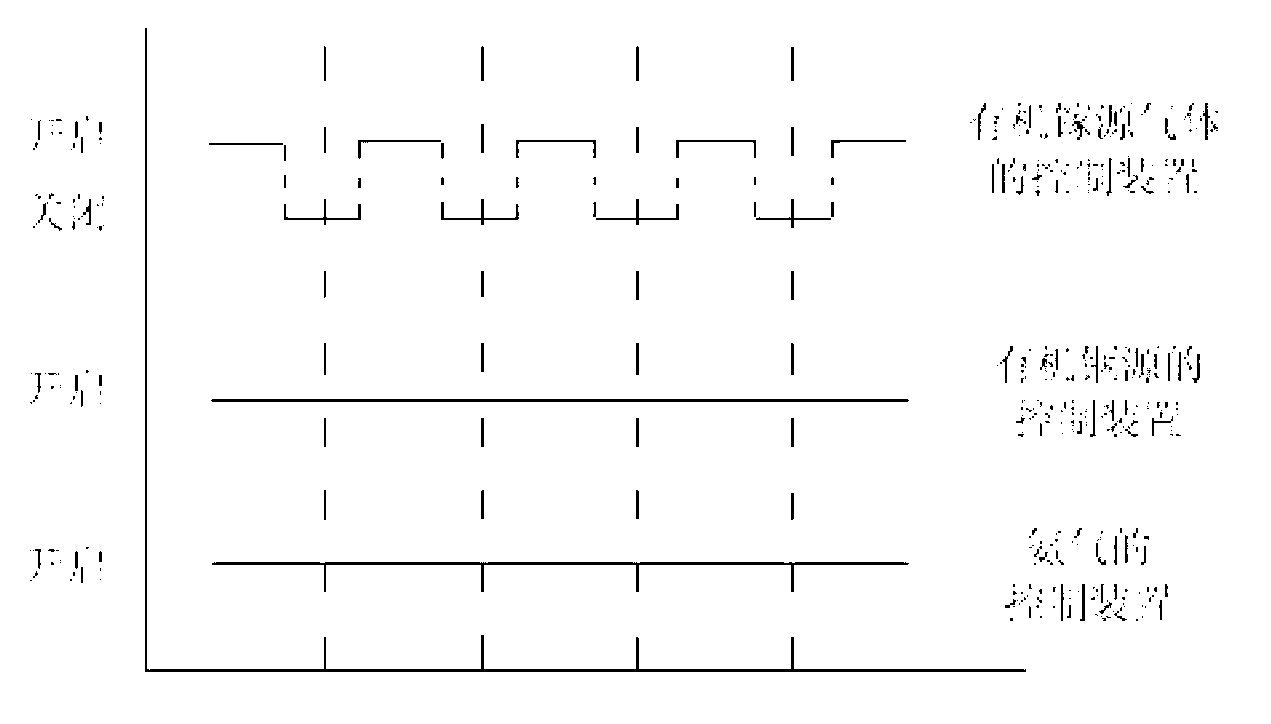

[0034] The flow chart of a certain growth cycle in the preparation method of the InGaN-based multiple quantum well structure provided by Embodiment 1 of the present invention is as follows figure 1 As shown, here "one growth cycle" (the same below) refers to the growth of a potential barrier layer and an InGaN-based quantum well layer (such as Figure 7 In the process of adjacently arranged a quantum well layer 41 and a barrier layer 42), in the actual preparation process of the InGaN-based multi-quantum well structure, it is necessary to continuously perform several growth cycles, that is, to continuously grow multiple adjacent Arranged barrier layers and InGaN-based quantum well layers can form InGaN-based multiple quantum well structures (such as Figure 7 The multiple quantum well structure in 4). For example, when the multi-quantum well structure includes alternately arranged M+1 barrier layers and M quantum well layers, M growth cycles need to be performed continuously ...

Embodiment 2

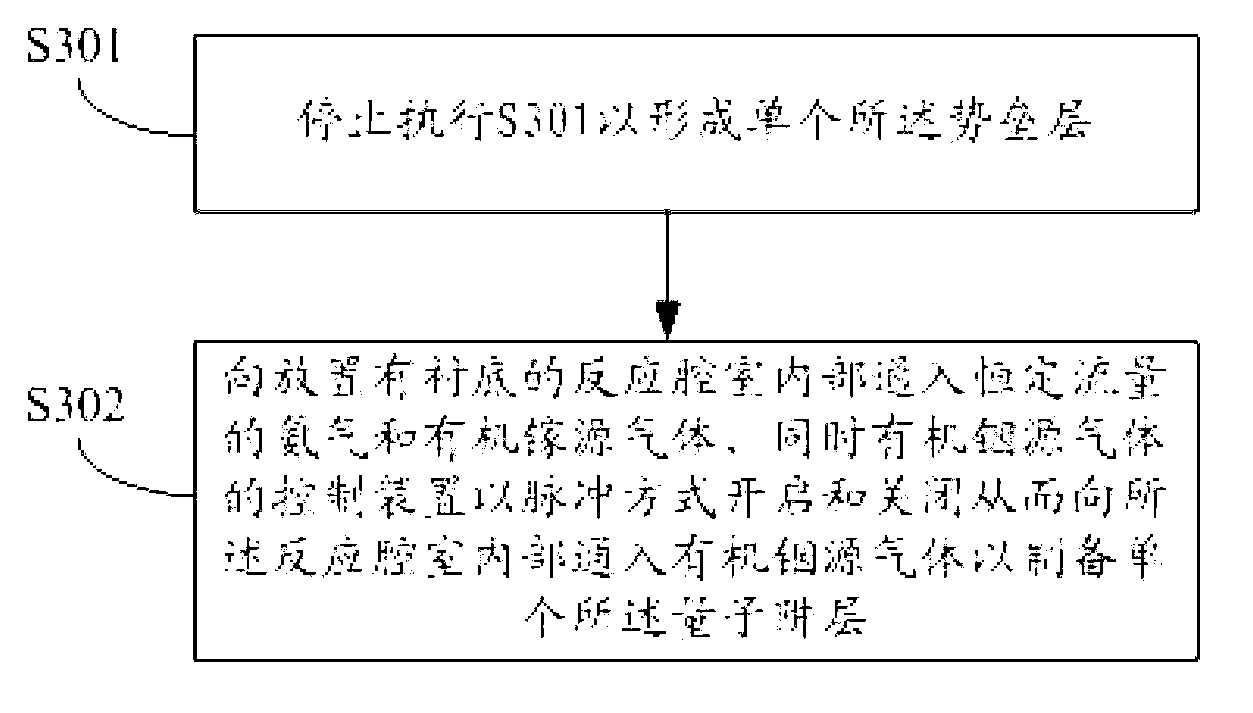

[0051] The flow chart of a certain growth cycle in the preparation method of the InGaN-based multiple quantum well structure provided by Embodiment 2 of the present invention is as follows image 3 shown.

[0052] In the second embodiment of the present invention, the following steps S301 and S302 are performed in a certain growth cycle:

[0053] Step S301: Introduce a constant flow of ammonia gas and organic gallium source gas into the reaction chamber to prepare a single barrier layer (see Figure 7 The barrier layer 42 in ), at this time, the barrier layer is GaN.

[0054] Step S302: Continuously feed organic gallium source gas and constant flow ammonia gas into the reaction chamber where the substrate is placed, and at the same time, the control device for organic indium source gas is turned on and off in a pulsed manner to vent into the organic indium source gas to prepare a single InGaN-based quantum well layer (see Figure 7 quantum well in 41).

[0055] In this ste...

Embodiment 3

[0063] The flow chart of a certain growth cycle in the preparation method of the InGaN-based multiple quantum well structure provided by Embodiment 3 of the present invention is as follows Figure 5 shown.

[0064] In the third embodiment of the present invention, the following steps S501 and S502 are performed in a certain growth cycle:

[0065] Step S501: Introduce a constant flow of ammonia gas and organic gallium source gas into the reaction chamber to prepare a single barrier layer (see Figure 7 The barrier layer 42 in ), at this time, the barrier layer is GaN.

[0066] Step S502: Continuously feed a constant flow of ammonia gas into the reaction chamber where the substrate is placed, and at the same time, the control device for the organic gallium source gas is turned on and off in a first pulse manner, so as to feed the organic gallium source gas into the reaction chamber And the control device of the organic indium source gas is turned on and off in a second pulse m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com