Mixed positive-pole material for lithium ion battery

A technology of mixing positive electrode materials and lithium-ion batteries, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of inconsistency in the delithiation amount, easy occurrence of mixed discharge, and deterioration of battery performance, so as to improve the compaction density. Low, guaranteed lithium impurity content, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

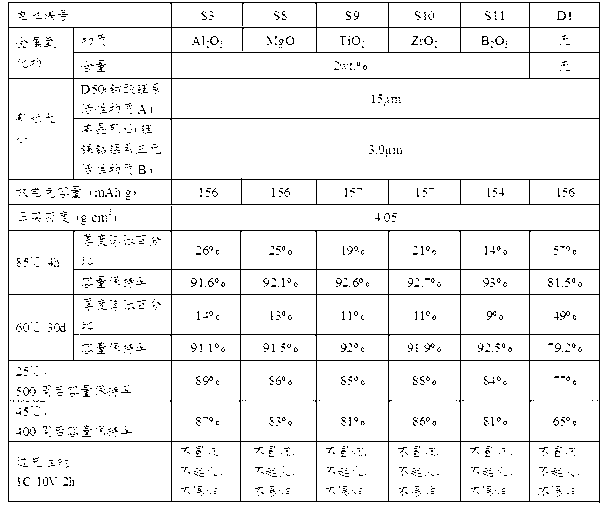

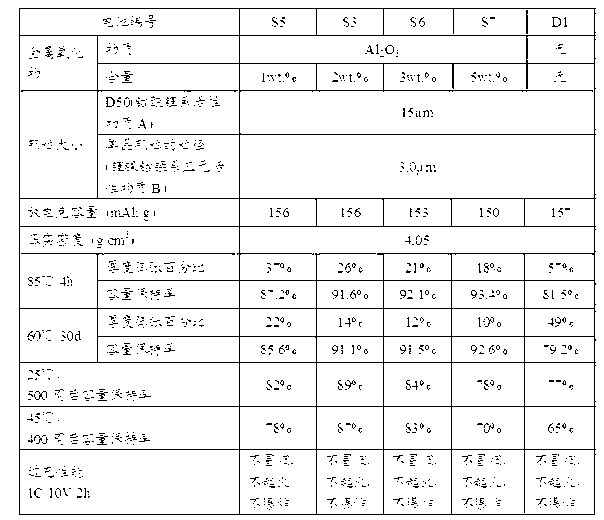

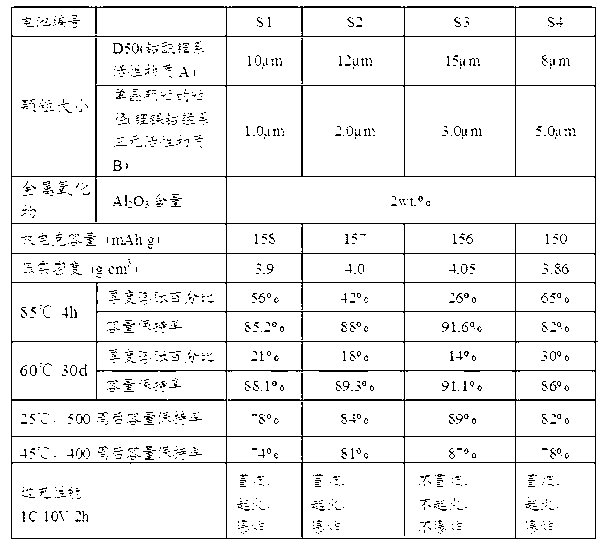

[0027] Embodiment 1: This embodiment provides a lithium-ion battery hybrid positive electrode material, the positive electrode material is LiCoO 2 and LiNi 0.5 co 0.2 mn 0.3 o 2 The hybrid material, among them, LiCoO 2 The median particle size D50 is 10μm, LiNi 0.5 co 0.2 mn 0.3 o 2 The particle size of the single crystal particles is 1 μm, LiNi 0.5 co 0.2 mn 0.3 o 2 and LiCoO 2 The mass ratio is 2:8, through the LiCoO 2 and LiNi 0.5 co 0.2 mn 0.3 o 2 Al was added during the mixing process 2 o 3 And after sintering, making Al 2 o 3 Evenly distributed in LiNi 0.5 co 0.2 mn 0.3 o 2 and LiCoO 2 surface, and makes LiNi 0.5 co 0.2 mn 0.3 o 2 and LiCoO 2 A molten network layer is formed between them.

[0028] Among them, the LiNi wrapped in the molten network layer 0.5 co 0.2 mn 0.3 o 2 and LiCoO 2 The total number of particles is from 2 to 50.

[0029] Melted network layer wrapped LiNi 0.5 co 0.2 mn 0.3 o 2 and LiCoO 2 The final diam...

Embodiment 2

[0033] Embodiment 2: The difference from Embodiment 1 is: LiCoO 2 The median particle size D50 of LiNi is 12μm; LiNi 0.5 co 0.2 mn 0.3 o 2 The particle size of the single crystal particles is 2 μm, and the others are the same as those in Example 1, and will not be repeated here.

Embodiment 3

[0034] Embodiment 3: Different from Embodiment 1: the positive electrode material is LiCo 0.9 Mg 0.1 o 2 and LiNi 0.5 co 0.2 Mg 0.3 o 2 of hybrid materials, where LiCo 0.9 Mg 0.1 o 2 The median particle size D50 of LiNi is 15μm; LiNi 0.5 co 0.2 Mg 0.3 o 2 The particle size of the single crystal particles is 3 μm, LiCo 0.9 Mg 0.1 o 2 and LiNi 0.5 co 0.2 Mg 0.3 o 2 The mass ratio is 1:5.

[0035] The sintering is LiCo 0.9 Mg 0.1 o 2 、LiNi 0.5 co 0.2 Mg 0.3 o 2 and Al 2 o 3 After the three are mixed evenly, the temperature is raised at a rate of 3°C / min, and the mixture is burned at a constant temperature of 900°C in an air atmosphere for 4 hours.

[0036] Others are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com