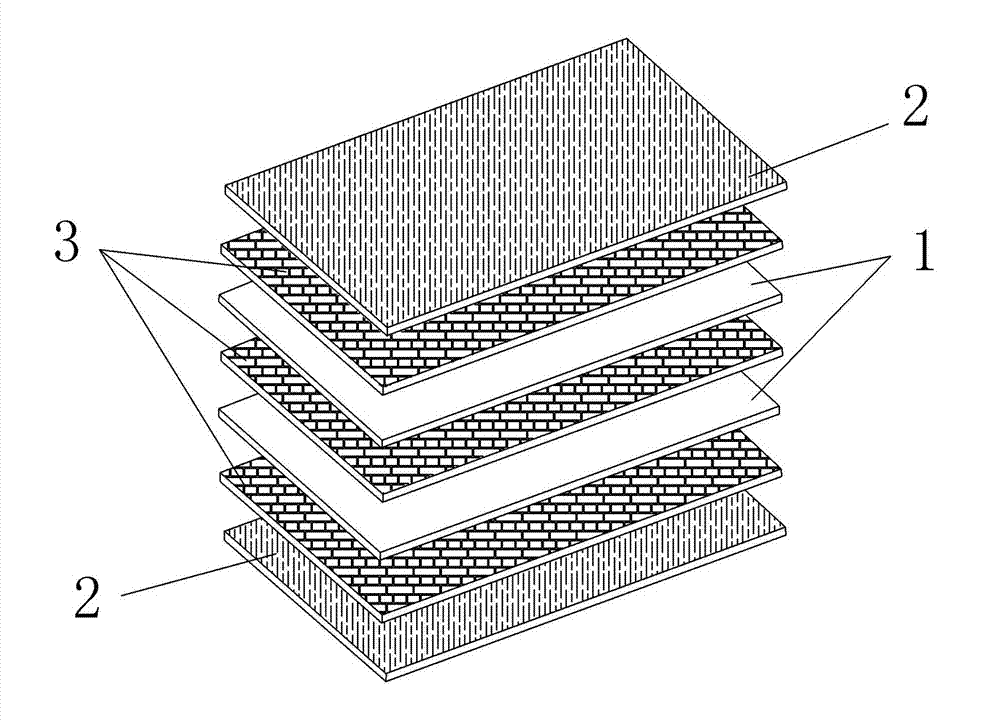

Method for manufacturing bamboo strengthened poplar laminated veneer lumber

A technology of poplar veneer and manufacturing method, which is applied in the jointing of wooden veneers, wood layered products, manufacturing tools, etc., can solve the problems of poor flame retardancy, uneven distribution, and irregular dry shape, and achieve Significant economic benefits, improved flame retardant performance, and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of manufacture method of bamboo reinforced poplar laminated veneer, comprises the following steps:

[0029] (1) Cutting of poplar veneer: rotary cut poplar to get 3mm veneer, sawing and cutting into format as required;

[0030] (2) Mitering of poplar veneer: Grind obliquely the sides that need to be joined until the angle formed by the inclined surface and the surface of the web is 20°, then apply glue to the inclined surface and perform 220° on the mitered joint. ℃ heating for 25 seconds to obtain mitered veneers;

[0031] (3) Impregnation of surface mitered veneers: water-based SiO 2 The sol is vacuum impregnated, the impregnation time is 2 hours, and the impregnation temperature is 25°C; the design pressure of the vacuum impregnation is 0.5MPa, the vacuuming time is 28min, and the vacuum degree is 0.08MPa;

[0032] (4) Bamboo curtain impregnation: place the bamboo curtains arranged in the forward direction in a phenolic resin with a solid content of 20% for ...

Embodiment 2

[0037] A kind of manufacture method of bamboo reinforced poplar laminated veneer, comprises the following steps:

[0038] (1) Cutting of poplar veneer: rotary cut poplar to get 1mm veneer, sawing and cutting into format as required;

[0039] (2) Mitering of poplar veneer: Grind obliquely the sides that need to be joined until the angle formed by the inclined plane and the surface of the web is 10°, then apply glue to the inclined plane and perform 250° ℃ heating for 30 seconds to obtain mitered veneers;

[0040] (3) Impregnation of surface mitered veneers: water-based SiO 2 The sol is vacuum impregnated, the impregnation time is 4 hours, and the impregnation temperature is 30°C; the design pressure of the vacuum impregnation is 0.3MPa, the vacuuming time is 25min, and the vacuum degree is 0.1MPa;

[0041] (4) Impregnation of bamboo rafts: vacuum impregnation of bamboo rafts in phenolic resin with a solid content of 30%, the impregnation time is 6 hours, and the impregnation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com