Synthetic method of SAPO-44 molecular sieve modified by rare earth metals

A SAPO-44, rare earth metal technology, applied in the synthesis field of SAPO-44 molecular sieve, can solve the problems of low catalytic activity, low selectivity of ethylene and propylene, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] According to Equation 1.6C 6 h 13 N:0.5SiO2 2 : 1.0Al 2 o 3 : 1.0P 2 o 5 : 70H 2 O:0.03Ce(NO 3 ) 3 Weigh out ingredients.

[0022] A certain amount of sodium aluminate solution with a concentration of 35wt% and phosphoric acid aqueous solution were fully stirred and mixed to form a uniform jelly, and cerium nitrate aqueous solution and orthosilicate were added sequentially under stirring, and finally a certain amount of template agent cyclohexylamine was slowly added. Add it to the above gel, mix well, put the above reaction mixture into a crystallization kettle with a polytetrafluoroethylene liner, crystallize at 190°C under autogenous pressure for 48 hours, and finally use the crystallized product Washed with ion water, filtered, and dried in air at 100°C, the obtained product was analyzed by XRD diffraction to be SAPO-44 molecular sieve, indicating that rare earth metal ions evenly entered the framework of the molecular sieve.

Embodiment 2

[0024] The original powders obtained in Comparative Example 1 and Example 2 were calcined at 600°C for 4.0 hours to remove the template agent, respectively pressed into tablets and crushed, and then sieved to take out the particle size parts of 20 to 40 mesh. The numbers were respectively S44-1, S44-2 Catalyst, pending evaluation.

Embodiment 3

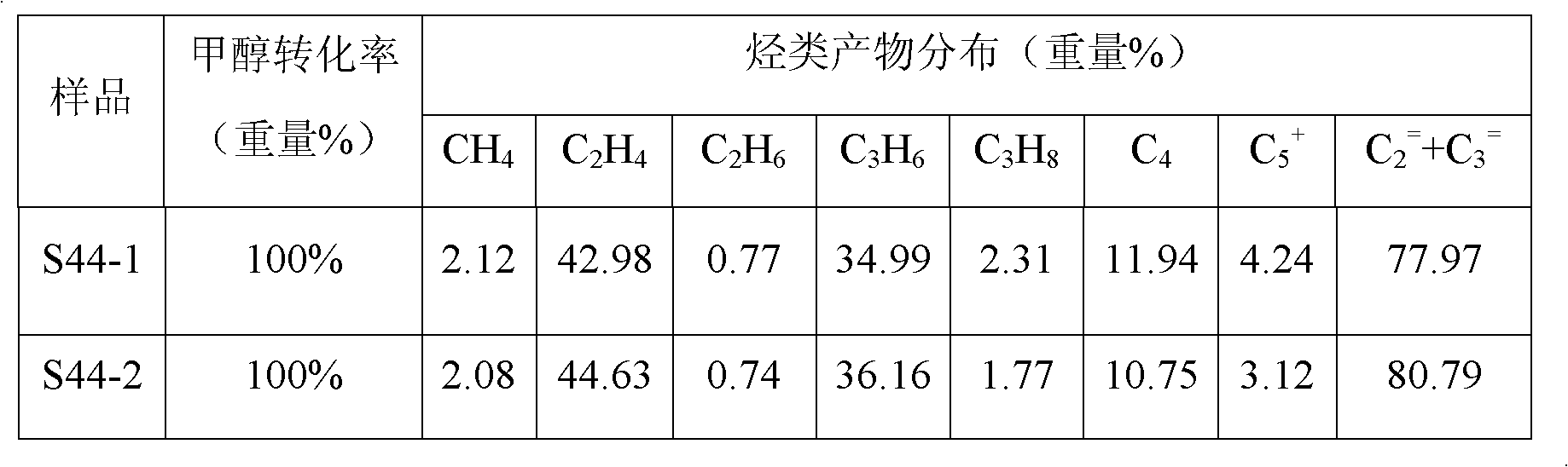

[0026] Using a fixed-bed catalytic reaction device, the S44-1 and S44-2 catalysts obtained in Comparative Example 1 and Example 1 were respectively subjected to catalyst evaluation experiments. Experimental conditions: the catalyst loading is 2.0 grams, the reaction temperature is 460°C, the reaction pressure is normal pressure, and the gravimetric space velocity of methanol is 6.0 hours -1 . The results are shown in Table 1.

[0027] Table 1

[0028]

[0029] As can be seen from Table 1, compared with the SAPO-44 molecular sieve without adding metal, the SAPO-44 molecular sieve sample containing metal cerium can improve the selectivity of low-carbon olefins, especially (ethylene+propylene).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com