Application method of combined reagent in copper and sulphur separation of ore beneficiation of covellite predominantly copper sulfide ore

A technology for combining chemicals and copper-sulfur separation, applied in solid separation, flotation and other directions, can solve the problems of unstable operation process, unsatisfactory copper-sulfur separation effect, etc., and achieve the effect of low toxicity and environmental friendliness of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

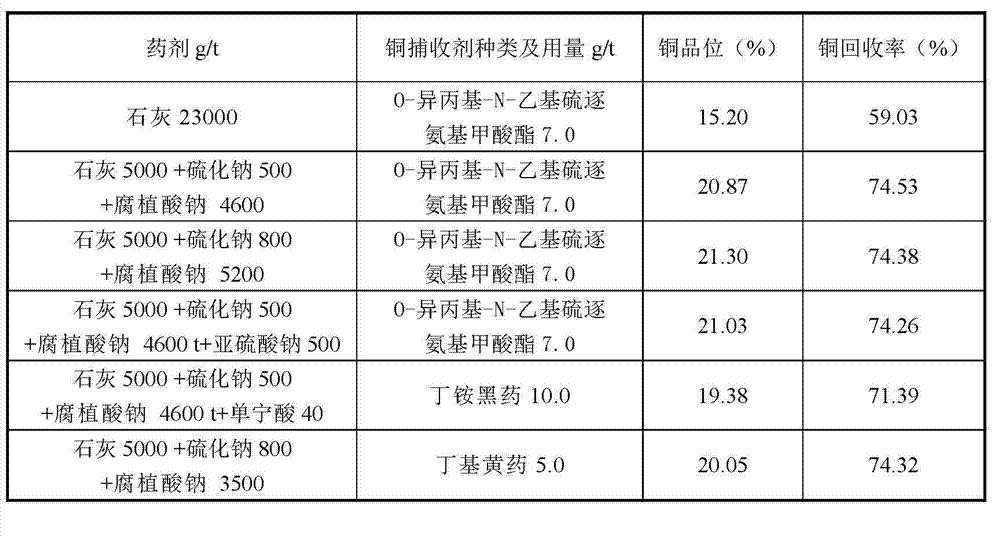

Embodiment 1

[0021] Using this method to treat copper-sulfur ore in a certain place in Tibet, the copper oxidation rate is 25.08%. The raw ore copper minerals of this ore are mainly copper blue and chalcocite, and the sulfur minerals are mainly pyrite.

[0022] After the raw ore is ground, use lime to adjust the slurry to make the pH of the raw ore slurry reach 7.5, add copper collector O-isopropyl-N-ethylsulfurethane 80 g / ton raw ore and butyl yellow 150 g / t raw ore flotation to obtain enriched copper-sulfur mixed concentrate;

[0023] Grind the copper-sulfur mixed concentrate to below 325 mesh, and add 600 g / t raw ore activated carbon to the mill;

[0024] A combination of sodium sulfide and sodium humate is added to the regrind mixed concentrate pulp.

[0025] Stir quickly and fully until the agent reaches the effect of inhibiting pyrite;

[0026] Copper collector is added to flotation to separate copper and sulfur, and copper concentrate is obtained through beneficiation, and sulfur...

Embodiment 2

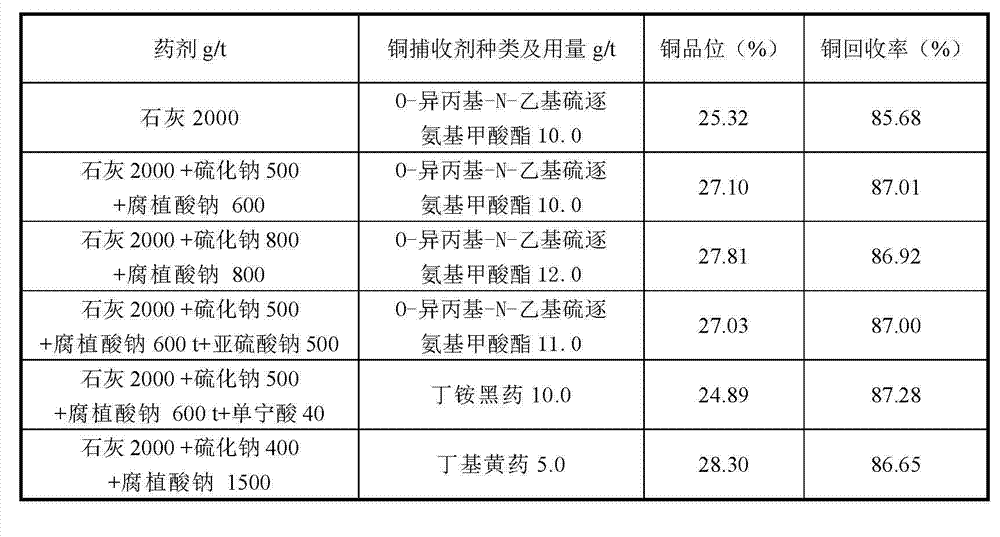

[0031] Using this method to treat copper-sulfur ore in a certain place in North Korea, the copper oxidation rate is 11.28%. The raw ore copper minerals of this ore are mainly copper blue and chalcocite, and the sulfur minerals are mainly pyrrhotite.

[0032] After the raw ore is ground, use lime to adjust the slurry to make the pH of the raw ore slurry reach 8.2, add copper collector O-isopropyl-N-ethylsulfurethane 50 g / ton of raw ore and butyl yellow 100 g / t raw ore flotation to obtain enriched copper-sulfur mixed concentrate;

[0033] Grind the copper-sulfur mixed concentrate to below 325 mesh, and add 100 g / t raw ore activated carbon to the mill;

[0034] The combined agent composed of sodium sulfide and sodium humate is added to the regrind copper-sulfur mixed concentrate slurry.

[0035] Stir quickly and fully until the agent reaches the effect of inhibiting pyrite;

[0036] Copper collector is added to flotation to separate copper and sulfur, and copper concentrate is...

Embodiment 3

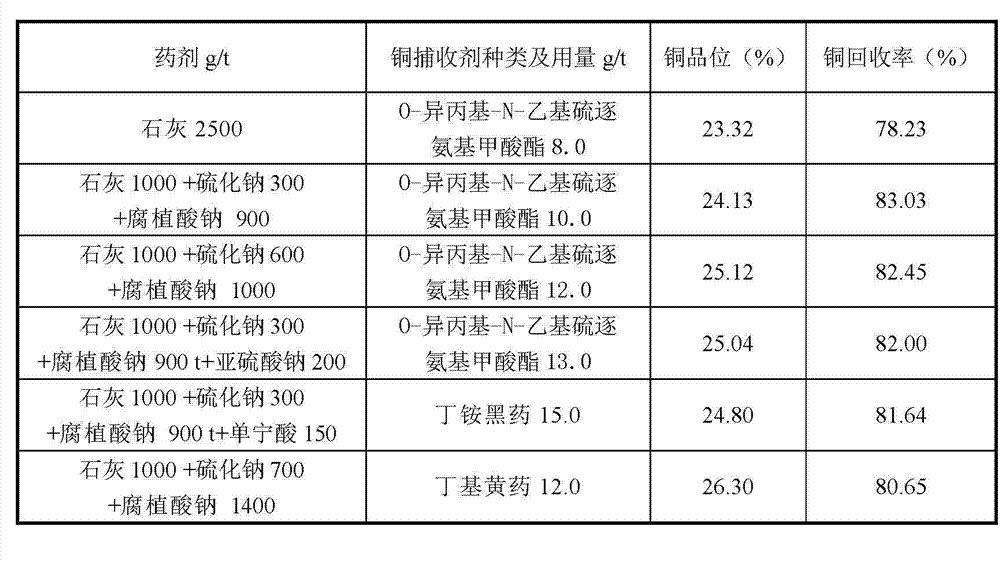

[0041] Using this method to treat copper-sulfur ore in a certain place in Xinjiang, the copper oxidation rate is 14.35%. The raw ore copper minerals of this ore are mainly copper blue and chalcocite, and the sulfur minerals are mainly pyrrhotite.

[0042] After the raw ore is ground, use lime to adjust the slurry to make the pH value of the raw ore slurry reach 8.6, add copper collector O-isopropyl-N-ethyl thiocarbamate 100 g / ton of raw ore and butyl yellow 60g / ton raw ore flotation to obtain enriched copper-sulfur mixed concentrate;

[0043] Grind the copper-sulfur mixed concentrate to below 325 mesh, and add 155 g / t raw ore activated carbon to the mill;

[0044] A combination of sodium sulfide and sodium humate is added to the regrind mixed concentrate pulp.

[0045] Stir quickly and fully until the agent reaches the effect of inhibiting pyrite;

[0046] Copper collectors are added to separate copper and sulfur by flotation, copper concentrate is obtained through concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com