A kind of black composite portland cement and production method thereof

A technology for compounding silicate and portland cement, applied in the direction of cement production and the like, can solve the problems of unfavorable popularization and application of black cement, difficulty in clinker production, complicated process, etc., and achieve favorable popularization and use, low cost, and production technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

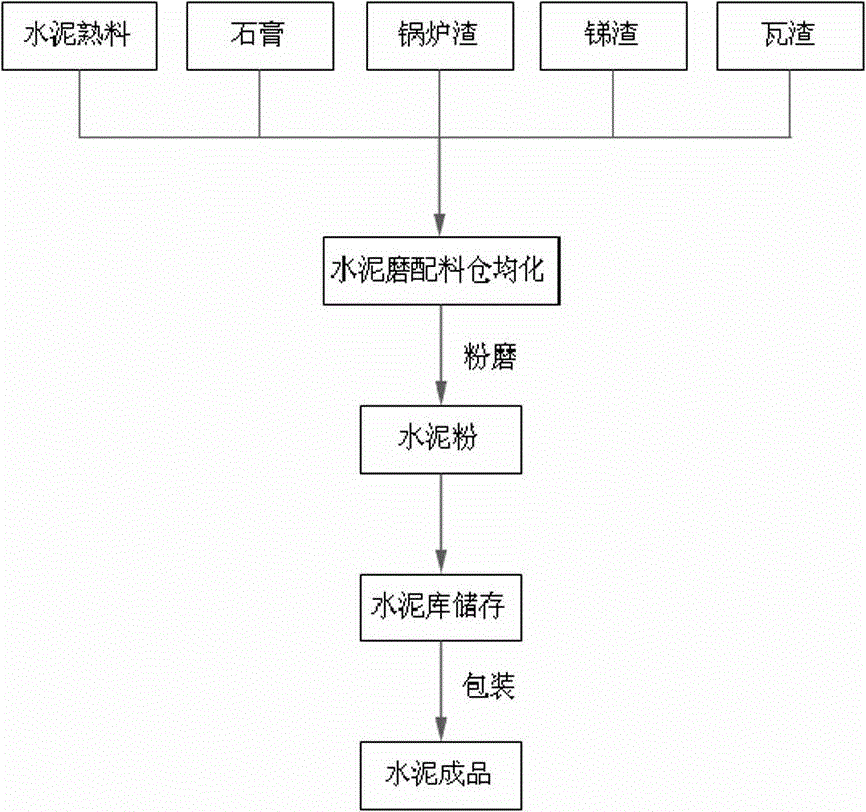

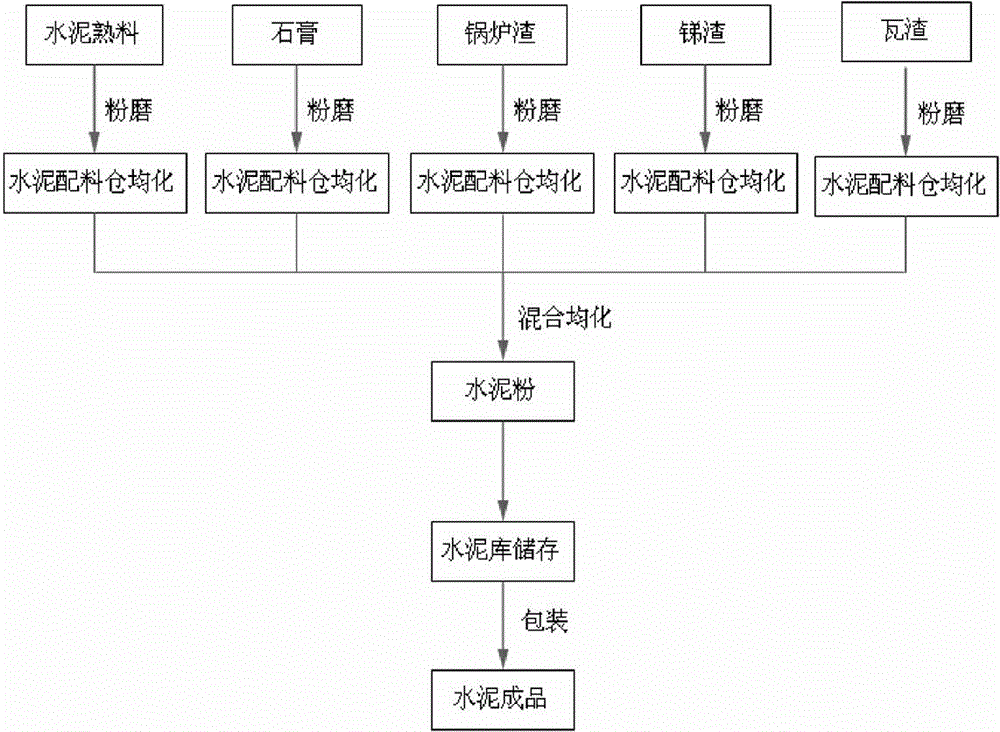

[0031] Manufacturers with ordinary Portland cement and composite Portland cement production, according to the mass percentage of 62% Portland cement clinker, 20% ordinary coal-fired boiler slag, 5% blast water quenching antimony slag, 8% Clay slag and 5% gypsum are prepared as raw materials, which are measured and transported to the cement mill batching bin according to the above proportions for homogenization and storage, and then transported to a ball mill for grinding until the specific surface area is greater than 350m 2 / kg or 0.08mm sieve is less than 4%, the ground cement is transported to the cement warehouse for storage, and is packed and shipped by a packaging machine or shipped in bulk.

Embodiment 2

[0033] For manufacturers with ordinary Portland cement and composite Portland cement, according to the mass percentage of 75% Portland cement clinker, 13% power station circulating fluidized bed slag, 3% blast furnace water-quenched antimony slag, 5% % of clay slag and 4% of gypsum are prepared as raw materials, which are measured and transported to the cement mill batching bin according to the above proportions for homogenization and storage, and then transported to the vertical mill for grinding until the specific surface area is greater than 350m 2 / kg or 0.08mm sieve is less than 2%, the ground cement is transported to the cement warehouse for storage, and is packaged and shipped by a packaging machine or shipped in bulk.

Embodiment 3

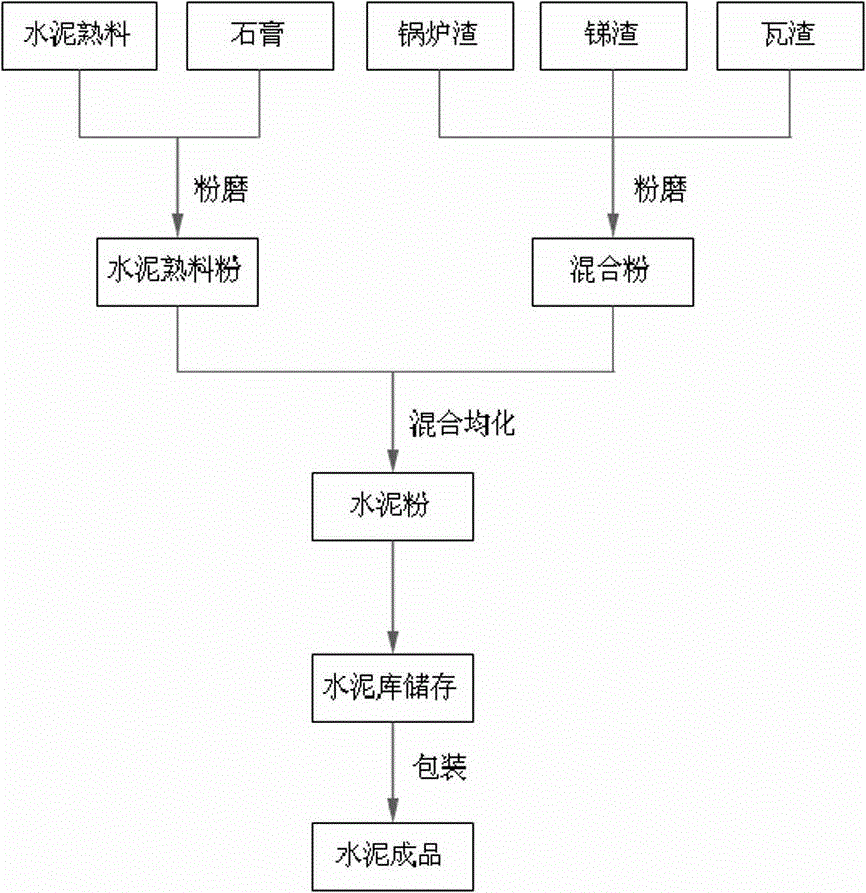

[0035] Manufacturers with the production of ordinary Portland cement and composite Portland cement prepare materials according to the mass percentage of 70% Portland cement clinker and 5% gypsum, and then measure and transport them to the ball mill for grinding until the specific surface area is greater than 350m 2 / kg or 0.08mm to sieve less than 3% clinker powder; according to the mass percentage of 15% boiling slag, 4% blast furnace water-quenched antimony slag, and 6% tile slag raw materials, they are then transported to the vertical mill by weighing scales Machine grinding until the specific surface area is greater than 350m 2 / kg or 0.08mm to sieve the mixed powder less than 3%; finally, mix and homogenize the clinker powder and the mixed powder to obtain cement powder, which is then transported to the cement warehouse for storage, and is packed and shipped by a packaging machine or shipped in bulk.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com