Treatment system and treatment method for continuous dynamic aerobic fermentation of organic waste

An organic waste and aerobic fermentation technology, applied in the field of urban organic waste treatment, can solve the problems of long fermentation period, difficult control, insufficient dynamic processing capacity, etc., and achieve the effect of improving treatment effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The continuous dynamic aerobic fermentation treatment system for organic waste provided in this embodiment can treat municipal solid waste, such as treating dewatered sludge produced in a sewage treatment plant, so that the treated sludge meets the stabilization requirements.

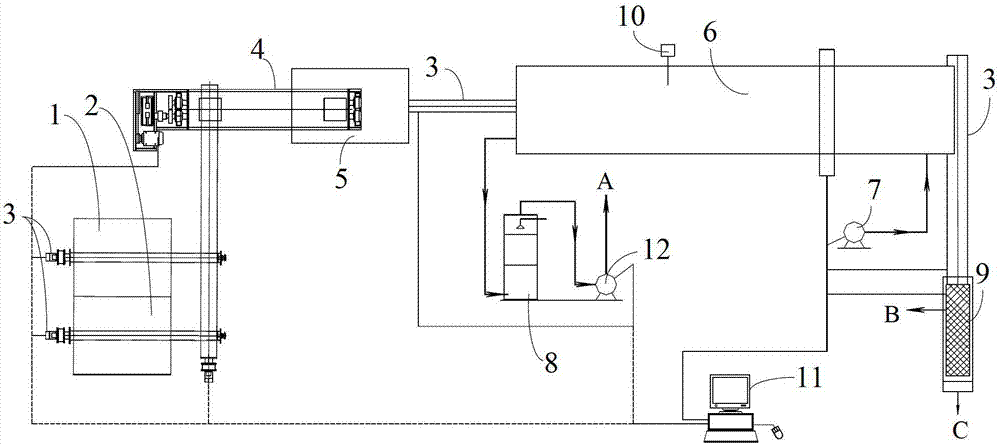

[0050] Such as figure 1 As shown, the system includes: auxiliary silo 1, organic waste silo 2, conveyor 3, mixer 4, mixing silo 5, aerobic fermentation drum 6, first fan 7, second fan 12, waste gas treatment Tower 8, screening machine 9, online detector 10 and control subsystem 11;

[0051] Among them, the conveyor 3 is connected to the auxiliary silo 1 and the organic waste silo 2 respectively. The discharge of the auxiliary silo 1 and the organic waste silo 2 is connected to the mixing silo 5, the aerobic fermentation drum 6 and the screening machine in turn through the conveyor. 9 connections;

[0052] The aerobic fermentation drum 6 is a fully enclosed external rotary fermentation drum. Through the...

Embodiment 2

[0066] This embodiment provides a continuous dynamic aerobic fermentation treatment system for organic waste. The system structure is basically the same as the system given in the first embodiment above. The difference is that a crushing device is provided in the auxiliary silo 1 and the organic waste silo 2. , The crushing device can crush the reprocessed domestic garbage after screening.

[0067] Use the above aerobic fermentation system to ferment the municipal solid waste, and place the municipal solid waste fully mixed with the fermentation auxiliary materials and part of the fermentation materials in the auxiliary silo 1 and the organic waste bin 2 for temporary storage, and pass the conveyor 3 The organic waste and auxiliary materials in the auxiliary silo 1, the organic waste silo 2 are sent to the mixing silo 5 for mixing by the mixer 4, and the mixed materials are temporarily stored or passed through the mixing silo 5. The conveyor 3 is transported to the aerobic fermen...

Embodiment 3

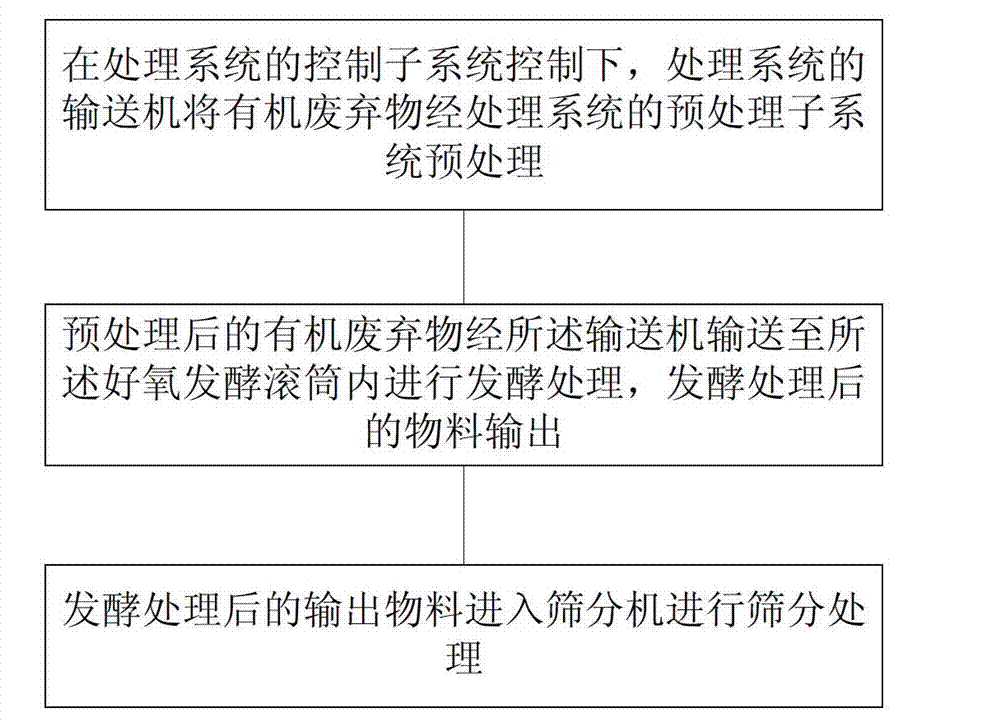

[0070] This embodiment provides a continuous dynamic aerobic fermentation treatment method for organic waste, which can treat municipal solid waste so that the treated product meets the stabilization requirements. Such as image 3 As shown, the method is a method of using the organic waste continuous dynamic aerobic fermentation treatment system of the foregoing embodiment 1 or embodiment 2, and includes the following steps:

[0071] Under the control of the control subsystem of the treatment system, the conveyor of the treatment system preprocesses the organic waste through the pretreatment subsystem of the treatment system;

[0072] The pretreated organic waste is transported by a conveyor to the aerobic fermentation drum for fermentation treatment, and the material after the fermentation treatment is output;

[0073] The control subsystem of the processing system controls the operation status of each device to complete the continuous dynamic aerobic fermentation treatment of orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com