Isonicotinic acid ester and preparation method thereof

A technology of isonicotinic acid ester and isonicotinic acid is applied in the field of new isonicotinic acid ester compounds and their preparation, and can solve the problems of difficult separation of concentrated sulfuric acid and products, inability to regenerate concentrated sulfuric acid, strong oxidizing property of concentrated sulfuric acid, and the like, To achieve the effect of low equipment investment and operating costs, short response time and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

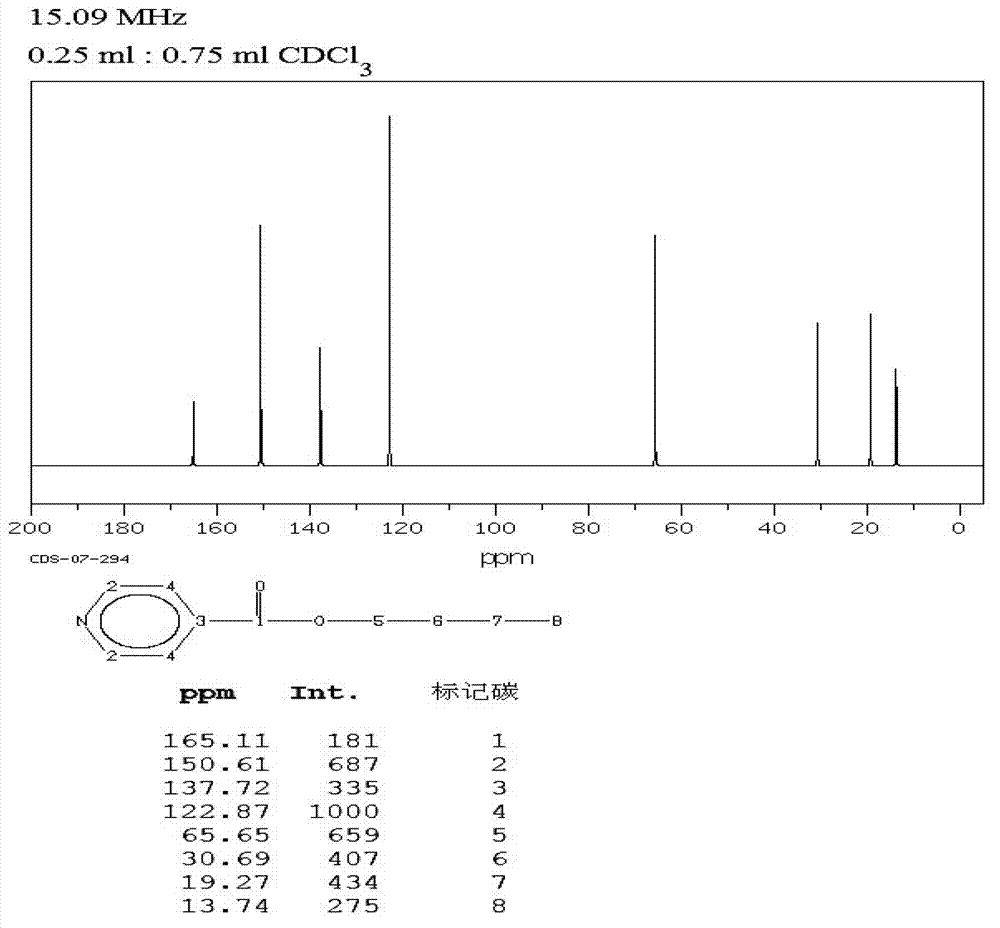

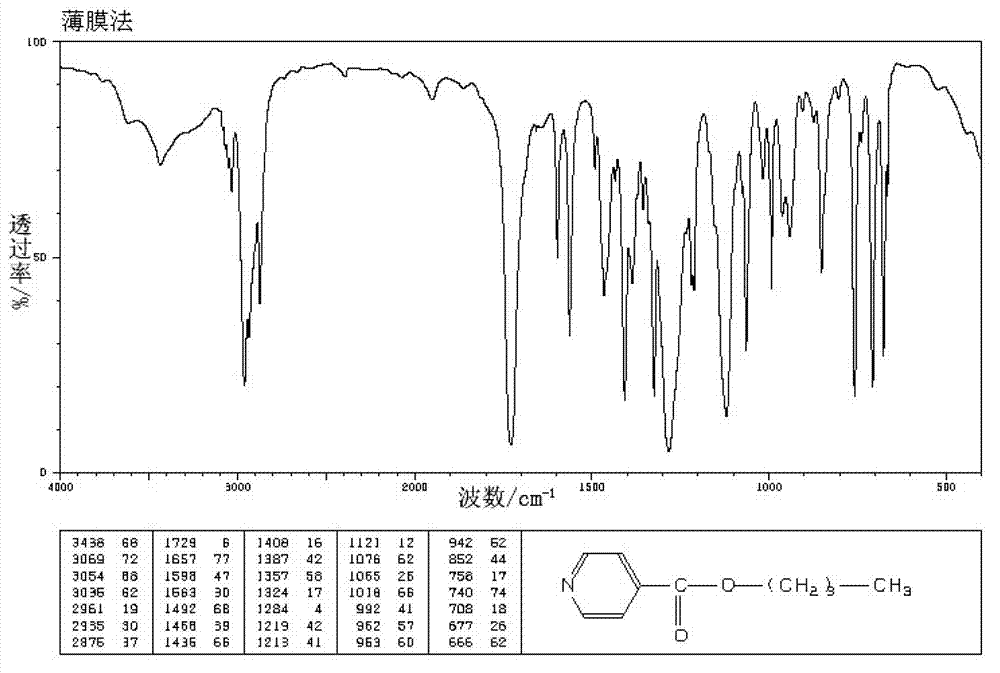

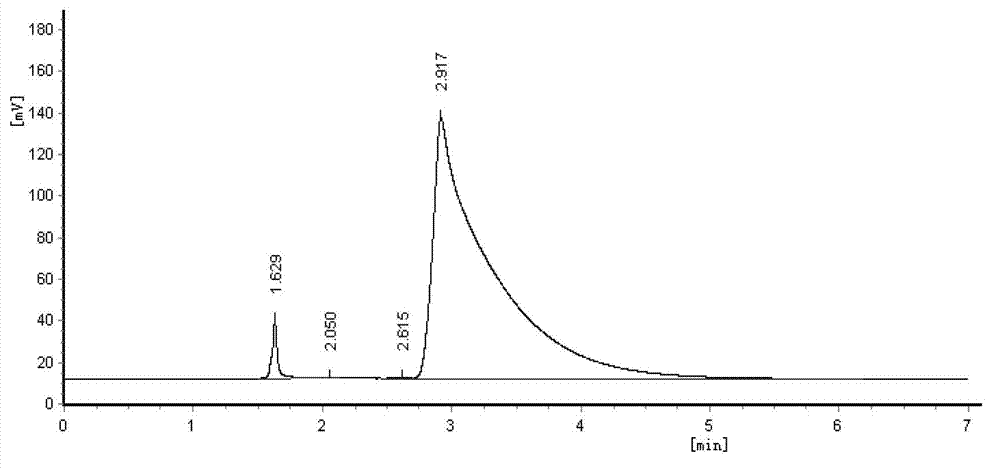

Image

Examples

Embodiment 1

[0033] In a 1-liter four-neck flask equipped with a stirrer, a reflux condenser, and a dropping funnel, add 1.0 mol of isonicotinic acid and 1 mol of n-butanol, fill with nitrogen for protection, and add 100% of the total volume of the water-carrying agent in the water separator. 1 / 3 of the hexane with water agent is heated with an oil bath, and the stirrer is started, and 5.0g of stannous oxalate solid acid catalyst is added, heated and stirred under normal pressure, and when the water produced by the reaction flows out from the water separator, start Timing, the reaction temperature is maintained at 120 ° C ~ 130 ° C, when no more water enters the water separator, the reaction is complete, the reaction solution is filtered, the filter cake is isonicotinic acid and a solid catalyst can be used for recycling, and the filtrate is firstly treated with 20% carbonic acid Washing with sodium solution to weak alkalinity, then washing with water until the washing water is neutral, sta...

Embodiment 2

[0035] In a 1-liter four-neck flask equipped with a stirrer, a reflux condenser, and a dropping funnel, add 1.0 mol of isonicotinic acid and 2 mol of n-butanol, fill with nitrogen for protection, and add 100% of the total volume of the water-carrying agent in the water separator. 1 / 3 of the cyclohexane with water agent is heated with an oil bath, and the stirrer is started, and the 5.0g stannous oxalate solid acid catalyst that is recycled after the reaction of Example 1 is added, and heated under normal pressure to reflux and stir. When the water flows out of the water separator, start timing, and keep the reaction temperature at 120°C to 130°C. When no more water enters the water separator, the reaction is complete, and the reaction liquid is filtered, and the filter cake is isonicotinic acid and solid menstrual catalyst. It can be used for recovery and circulation. The filtrate is first washed with 20% sodium carbonate solution to weak alkalinity, and then washed with water ...

Embodiment 3

[0037] In a 1-liter four-neck flask equipped with a stirrer, reflux condenser, and dropping funnel, add 1.0 mol of isonicotinic acid and 3 mol of n-butanol, fill with nitrogen for protection, do not add water-carrying agent, heat with an oil bath, and start Stirrer, add the 5.0g stannous oxalate solid acid catalyst that embodiment 2 has reacted and recycles, carry out normal pressure heating and reflux stirring, when the water that is to be reacted flows out from the water trap, start timing, and the reaction temperature is maintained at 120° C. to 130° C. ℃, when no more water enters the water separator, the reaction is complete, and the reaction solution is filtered, and the filter cake is isonicotinic acid and solid menstrual catalyst can be used for recycling, and the filtrate is first washed with 20% sodium carbonate solution to weak alkalinity , and then washed with water until the washing water is neutral, standing for stratification, distilling the upper organic layer u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com