Synthesis method of 1-(3-chloro-2-pyridyl)-1H-pyrazole-5-formate

A synthesis method and a formate technology are applied in the field of broad-spectrum insecticide chlorantraniliprole pesticides, which can solve the problems of expensive raw materials and high industrial production costs, reduce equipment corrosion and harm to the health of operators, The effect of cost reduction and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

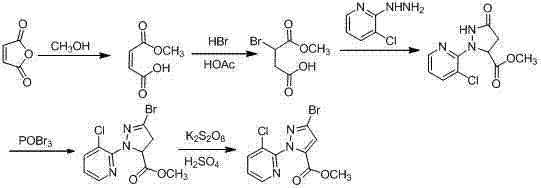

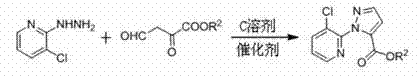

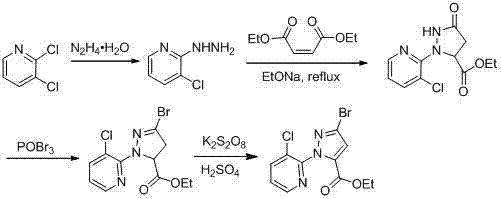

Method used

Image

Examples

Embodiment 1

[0046] (1) Take a 50 mL three-necked flask, add a reflux condenser, and install a drying tube with anhydrous calcium chloride on the top of the condenser. Add 5 mL (123 mmol) of anhydrous methanol to the three-necked flask, and add 0.54 g (10 mmol) of sodium methoxide. When the sodium methoxide is completely dissolved, put the three-necked flask into a low-temperature reactor and cool to 0°C. At this temperature, a mixture of methyl formate (0.78 mL, 13 mmol) and methyl pyruvate (0.75 mL, 8.3 mmol) was slowly added dropwise. After the dropwise addition was completed, the mixture was stirred at this temperature for 10 hours, and then rotary evaporated to dryness. Add 5 mL of cold diethyl ether to the evaporated solid to dissolve, and filter to obtain a khaki solid sodium salt of methyl 2,4-dioxobutyrate. After drying, the weight is 0.85 g, and the yield is 67% (based on Calculate the amount of methyl pyruvate).

[0047](2) Take 1.52 g (10 mmol, sodium salt of methyl 2,4-dioxo...

Embodiment 2

[0049] (1) Take a 50 mL three-necked flask, add a reflux condenser, and install a drying tube with anhydrous calcium chloride on the top of the condenser. Add 10 mL (246 mmol) of anhydrous methanol to the three-necked flask, and add 0.54 g (10 mmol) of sodium methoxide. When the sodium methoxide is completely dissolved, put the three-necked flask into a low-temperature reactor and cool to 0°C. At this temperature, a mixture of methyl formate (1.08 mL, 18 mmol) and methyl pyruvate (0.75 mL, 8.3 mmol) was slowly added dropwise. After the dropwise addition was complete, it was stirred at this temperature for 10 hours. Rotary evaporate to dryness, add 5 mL of cold diethyl ether to the solid, filter to obtain khaki solid sodium salt of methyl 2,4-dioxobutyrate, weigh 0.86 g after drying, and the yield is 55% (based on Calculate the amount of methyl pyruvate).

[0050] (2) Take 1.52 g (10 mmol) of methyl 2,4-dioxobutyrate sodium salt obtained in (1) above, dissolve it in 10 mL of ...

Embodiment 3

[0052] (1) Take a 50 mL three-necked flask, add a reflux condenser, and install a drying tube with anhydrous calcium chloride on the top of the condenser. Add 5 mL (123 mmol) of anhydrous methanol to the three-necked flask, and add 0.54 g (10 mmol) of sodium methoxide. When the sodium methoxide is completely dissolved, put the three-necked flask into a low-temperature reactor and cool to 0°C. At this temperature, a mixture of methyl formate (0.78 mL, 13 mmol) and methyl pyruvate (0.75 mL, 8.3 mmol) was slowly added dropwise. After the dropwise addition was complete, it was stirred at this temperature for 10 hours. Rotary evaporate to dryness, add 5 mL of cold diethyl ether to the solid, filter to obtain khaki solid sodium salt of methyl 2,4-dioxobutyrate, weigh 1.02 g after drying, and the yield is 75% (based on Calculate the amount of methyl pyruvate).

[0053] (2) Take 1.52 g (10 mmol) of methyl 2,4-dioxobutanoate sodium salt in (1) above, dissolve it in 10 mL of methanol,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com