A kind of curing agent for attapulgite enhanced printing and dyeing sludge treatment and disposal and its curing method

A technology for attapulgite and printing and dyeing sludge, which is applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of low mechanical strength of sludge solidified body and high leaching concentration of pollutants, and achieves good generalizability and practicability , Good fixation effect and low cost components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An attapulgite-enhanced solidifying agent for treatment and disposal of printing and dyeing sludge in this embodiment includes composite additives and attapulgite, and the composite additives include cement, fly ash and calcium chloride. According to the sludge moisture content, organic matter content and heavy metal content and the application purpose of sludge solidification, combined with the design software design expert8.0.6, after creating a new task, select the Optimal type in the mixture tab, set the number of components and the maximum and minimum of each component value. After selecting the response index, determine the proportion of each component contained in the composite additive and the addition ratio of the composite additive and attapulgite. In view of the fact that the solidified printing and dyeing sludge obtained in this embodiment is mainly used for sanitary landfill. The mass ratio of cement, fly ash and calcium chloride in the composite additive ...

Embodiment 2

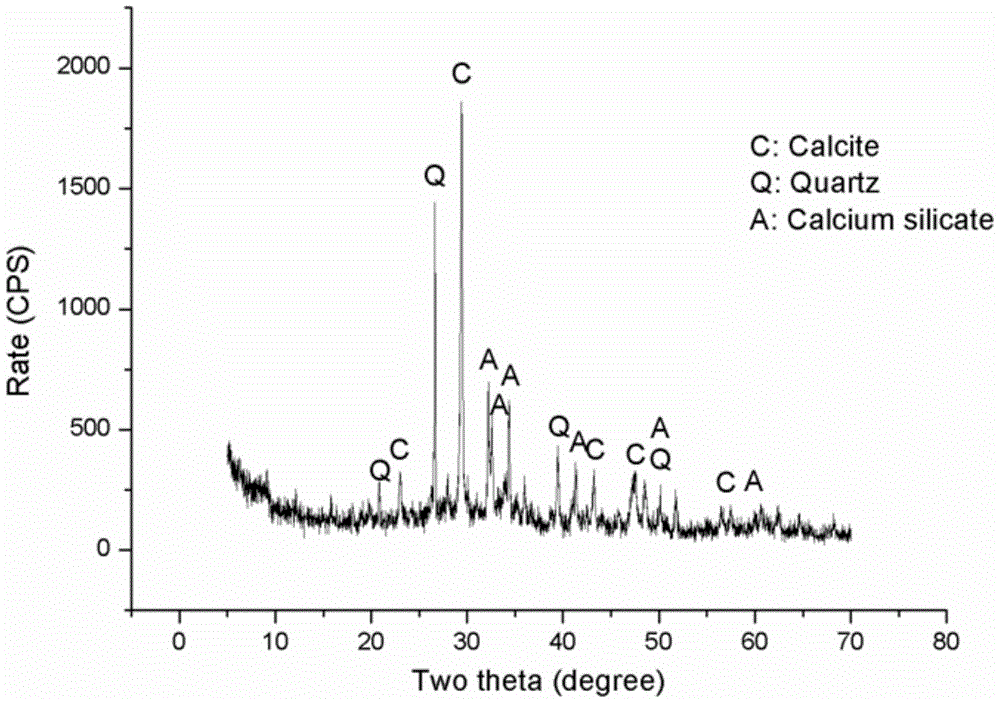

[0035] In this example, the composite additive is first mixed according to cement: fly ash: calcium chloride = 1:0:0, and then the components are mixed according to printing and dyeing sludge: attapulgite: composite additive = 0.433:0.133:0.433 solidified. Add 133g of attapulgite and 433g of cement to 433g of printing and dyeing sludge according to the above ratio, and mix evenly. Put it into a 70.7mm×70.7mm×70.7mm mold at room temperature for 24 hours and mold it. After demolding and curing for 28 days, the unconfined compressive strength of the cured block reaches 3.0MPa. Meet the compressive strength requirements for soil base and road construction bricks in Evaluation of physical stability and leachability of Portland Pozzolona Cement (PPC) solidified chemical sludge generated from textile wastewater treatment plants, Journal of Hazardous Materials 207:56-64 published by Patel. XRD results show that quartz and calcite are the main components, and figure 1 similar. Adopt...

Embodiment 3

[0037] A kind of attapulgite reinforced printing and dyeing sludge curing agent and its curing method of this embodiment are basically the same as embodiment 1, the difference is: in this embodiment cement: fly ash: calcium chloride=6 : 0: 0.18, printing and dyeing sludge: attapulgite: composite additive = 0.1: 0.05: 0.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com