Synthesis method for 3-nitryl-4-hydroxyl phenylarsonic acid

A technology of hydroxyphenylarsinic acid and a synthesis method, applied in the chemical field, can solve the problems of inability to recycle the reaction solution, troublesome waste water treatment, large consumption of raw materials, etc., and achieve the effects of low cost, high utilization rate of raw materials and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

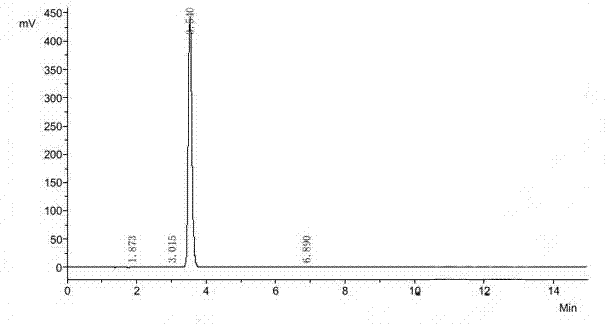

Image

Examples

Embodiment 1

[0022] Add 500kg of arsenic acid aqueous solution (mass concentration 85%), 100kg of o-nitroaniline, 10kg of chloroform, and 0.5kg of β-cyclodextrin into a 2000L enamel pot. When ready, start stirring and heat up, and the reaction temperature is controlled at 135~ 160°C, start the reaction timer, and the reaction time is about 5.5 hours. After the reaction, turn off the steam, concentrate and recover the dehydrating agent under normal pressure, and obtain the concentrated liquid. Filter after cooling to obtain filter cake A and filtrate A. The filter cake A is 3-nitro-4-aminophenylarsine acid condensation material, and the filtrate A is recycled. Add water to the filter cake A and raise the temperature to 70 ° C. Add liquid alkali to adjust the pH value to 4 After dissolving, adsorbed by an adsorbent, cool to 55°C and filter to obtain filter cake B and filtrate B filtrate, add alkali to hydrolyze the B filtrate, react for a certain time and temperature, and obtain 3-nitro-4-hyd...

Embodiment 2

[0024] Add 1200kg of arsenic acid aqueous solution (mass concentration 85%), 100kg of o-nitroaniline, 10kg of polyacrylamide, 0.5kg of β-cyclodextrin into a 2000L enamel pot. When ready, start stirring and heat up, and the reaction temperature is controlled at 135- 160°C, start the reaction timing, the reaction time is about 5.0 hours, after the reaction is over, turn off the steam, concentrate and recover the dehydrating agent under normal pressure, and obtain the concentrated liquid, add water to the condensed liquid for analysis and release, and stir for 0.5 h to obtain the reaction liquid, the reaction liquid Filter after cooling to obtain filter cake A and filtrate A. The filter cake A is 3-nitro-4-aminophenylarsine acid condensation material, and the filtrate A is recycled. Add water to the filter cake A and raise the temperature to 70 ° C. Add liquid alkali to adjust the pH value to 12 After dissolving, adsorbed by an adsorbent, cool to 55°C and filter to obtain filter c...

Embodiment 3

[0026] Add 900kg of arsenic acid aqueous solution (mass concentration 85%), 100kg of o-nitroaniline, 10kg of tetrachloroethylene, 0.5kg of n-octanoic acid into a 2000L enamel pot. When ready, stir and heat up. The reaction temperature is controlled at 135-160°C. Start the reaction timing, and the reaction time is about 5.5 hours. After the reaction is over, turn off the steam, concentrate and recover the dehydrating agent under normal pressure, and obtain the concentrated liquid. Add water to the condensed liquid for analysis and release, and stir for 1 hour to obtain the reaction liquid. The reaction liquid is cooled and filtered. Filter cake A and filtrate A are obtained, filter cake A is 3-nitro-4-aminophenylarsine acid condensation material, filtrate A is recycled, filter cake A is heated to 70°C by adding liquid alkali to adjust the pH value to 14 after being dissolved and then adsorbed After absorbing the agent, cool to 55°C and filter to obtain the filter cake B and filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com