Hydroxy acrylic resin for reflective film and preparation method thereof

A technology of hydroxyacrylic acid and methacrylic acid, applied in the field of hydroxyacrylic resin for reflective film and its preparation, can solve the problems of poor flexibility and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

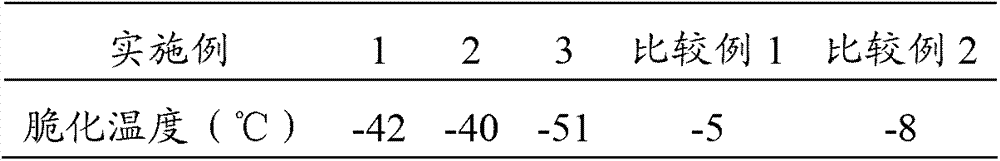

Examples

preparation example Construction

[0037] The invention provides a preparation method of hydroxyacrylic resin for reflective film, comprising the following steps:

[0038] a) Mixing the first acrylic monomer, the second acrylic monomer, the third acrylic monomer and the first mass part initiator to obtain a monomer mixture material, the first acrylic monomer is an unsubstituted acrylate compound , the second acrylic monomer is a methacrylate compound, and the third acrylic monomer is a hydroxy acrylate compound;

[0039] b) Adding the monomer mixture material dropwise into an organic solvent to obtain a reaction liquid, the temperature of the organic solvent is 80°C~120°C;

[0040] c) After the addition of the monomer mixture is completed, a second mass part of an organic solution of an initiator is added dropwise to the reaction solution, and a hydroxyacrylic resin is obtained after the reaction is completed.

[0041] In the present invention, the first acrylic monomer, the second acrylic monomer, the third a...

Embodiment 1

[0056] Add 130kg of xylene into a 500L reaction kettle equipped with a condensation tower, water separator and head tank, and heat the xylene to 120°C;

[0057] Add 12kg ethyl acrylate, 15kg butyl acrylate, 35kg methyl methacrylate, 67kg n-butyl methacrylate, 24kg acrylate-2-hydroxypropyl and 1.4kg peroxy-2-ethylhexanoic acid in the stirring tank For tert-butyl ester, after stirring evenly, the obtained monomer mixture material is transported to the head tank equipped with toluene through the anti-corrosion pump, and the monomer mixture material is added dropwise to the reaction kettle through the head tank, and the time for dropping is 2.5 hours;

[0058] After the monomer is added dropwise, add 20kg of xylene pre-dissolved with 0.3kg of tert-butyl peroxy-2-ethylhexanoate dropwise into the reaction kettle. The dropwise addition takes 20 minutes, and then the insulation reaction is carried out at 120°C for 2 hours. , measure the content of the double bond in the reaction syste...

Embodiment 2

[0061] Add 100kg of xylene and 70kg of butyl acetate into a reaction kettle with a volume of 1 cubic meter equipped with a condensation tower, a water separator and a head tank, and heat the solvent obtained by mixing xylene and butyl acetate to 115°C;

[0062] Put 92kg of ethyl acrylate, 68kg of methyl methacrylate, 97kg of n-butyl methacrylate, 45kg of hydroxyethyl acrylate and 1.8kg of benzoyl peroxide in the stirring tank, stir the obtained single The monomer mixture material is transported to the head tank filled with the mixed solvent, and the monomer mixture material is added dropwise to the reaction kettle through the head tank, and the dropwise addition takes 3 hours;

[0063] After the addition of the monomers, 30kg of xylene pre-dissolved with 0.5kg of benzoyl peroxide was added dropwise into the reaction kettle, and the addition took 30 minutes, and then the insulation reaction was carried out at 115°C for 1.5 hours, and the double bond in the reaction system was meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com