Super-toughened nylon 66 nano composite material prepared by in situ compatibilization and preparation method thereof

A nano-composite material, nylon technology, applied in the field of materials, can solve the problems of low notched impact strength, poor dimensional stability, strong hygroscopicity, etc., and achieve the effects of high notched impact strength, good low temperature impact resistance, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] In-situ compatibilization preparation of super-tough nylon 66 nanocomposites is made of the following raw materials in parts by weight: 90 parts of nylon 66 (PA66), 10 parts of ethylene propylene diene monomer (EPDM), and dicumyl peroxide (DCP) 0.1 part, maleic anhydride (MAH) 1 part, organic montmorillonite (OMMT) 5 parts.

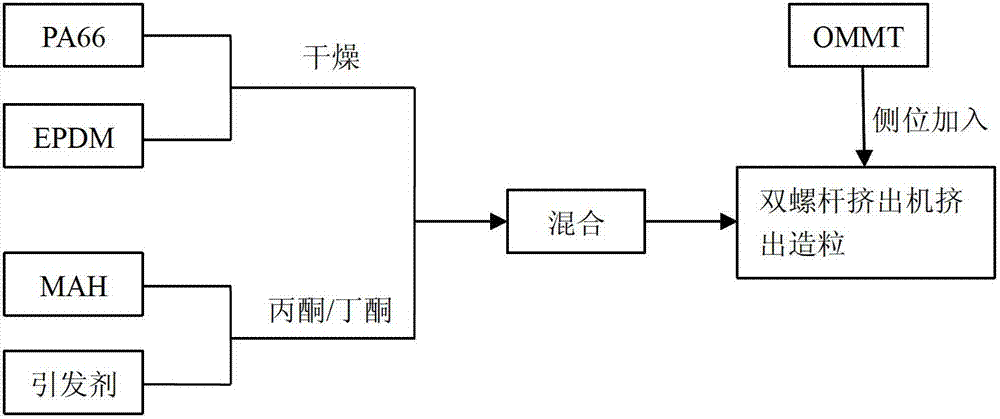

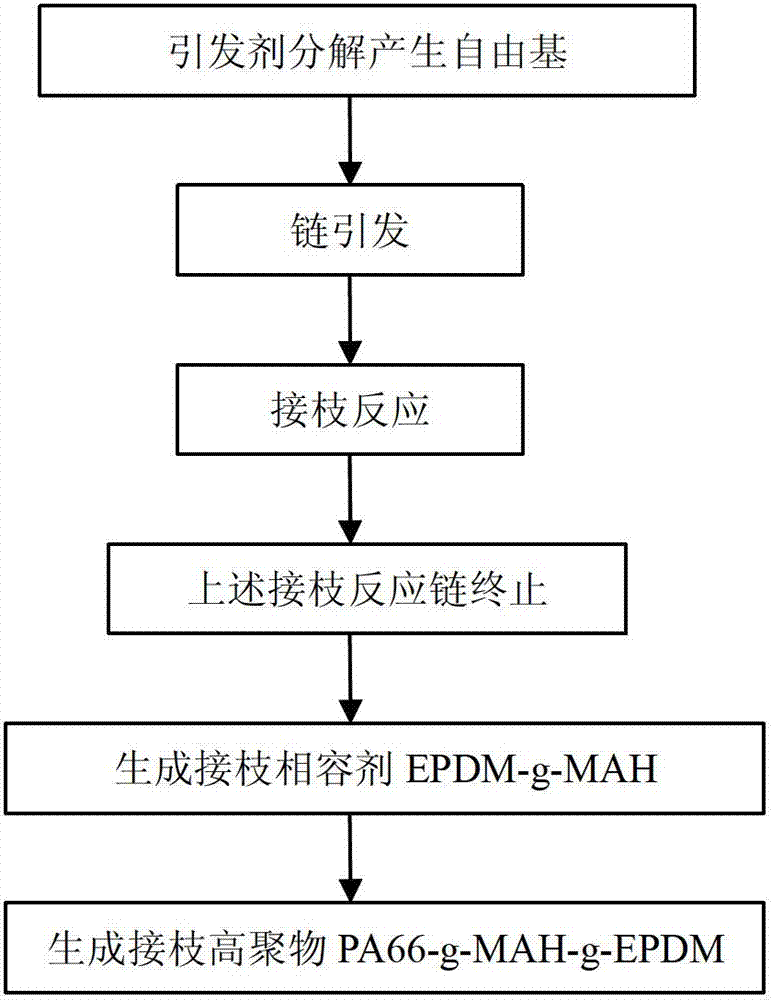

[0058] The method for preparing super-tough nylon 66 nanocomposite by in-situ compatibilization comprises the following steps:

[0059] (1) Dissolve the initiator dicumyl peroxide (DCP) and maleic anhydride (MAH) in methyl ethyl ketone to obtain a mixed solution, and place it for later use;

[0060] (2), place nylon 66 in a vacuum oven for drying treatment, control the oven temperature at 90°C, and dry for 4 hours, place EPDM in a vacuum oven for drying treatment, control the oven temperature at 70°C, and dry for 4 hours, Then nylon 66 and EPDM are cooled to room temperature, and the nylon 66 and EPDM after drying treatment are mixed uniformly acc...

Embodiment 2

[0064] Super-tough nylon 66 nanocomposites prepared by in-situ compatibilization are prepared from the following raw materials in parts by weight: 80 parts of nylon 66 (PA66), 20 parts of ethylene-propylene-diene rubber (EPDM), 2,5-dimethyl-2 , 0.1 part of 5-di-tert-butylperoxyhexane (L-101), 1 part of maleic anhydride (MAH), 5 parts of organic montmorillonite (OMMT).

[0065] The method for preparing super-tough nylon 66 nanocomposite by in-situ compatibilization comprises the following steps:

[0066] (1) Dissolve the initiator 2,5-dimethyl-2,5-di-tert-butylperoxyhexane (L-101) and maleic anhydride (MAH) in acetone to obtain a mixed solution, put aside;

[0067] (2), place nylon 66 in a vacuum oven for drying treatment, control the oven temperature at 90°C, and dry for 4 hours, place EPDM in a vacuum oven for drying treatment, control the oven temperature at 70°C, and dry for 4 hours, Then nylon 66 and EPDM are cooled to room temperature, and the nylon 66 and EPDM after dr...

Embodiment 3

[0071] Super-tough nylon 66 nanocomposites prepared by in-situ compatibilization are prepared from the following raw materials in parts by weight: 70 parts of nylon 66 (PA66), 30 parts of ethylene-propylene-diene rubber (EPDM), 2,5-dimethyl-2 , 0.1 part of 5-di-tert-butylperoxyhexane (L-101), 1 part of maleic anhydride (MAH), 5 parts of organic montmorillonite (OMMT).

[0072] The method for preparing super-tough nylon 66 nanocomposite by in-situ compatibilization comprises the following steps:

[0073] (1) Dissolve the initiator 2,5-dimethyl-2,5-di-tert-butylperoxyhexane (L-101) and maleic anhydride (MAH) in acetone to obtain a mixed solution, put aside;

[0074] (2), place nylon 66 in a vacuum oven for drying treatment, control the oven temperature at 90°C, and dry for 4 hours, place EPDM in a vacuum oven for drying treatment, control the oven temperature at 70°C, and dry for 4 hours, Then nylon 66 and EPDM are cooled to room temperature, and the nylon 66 and EPDM after dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com