Flame-retardant smoke-suspension asphalt for environment-friendly road and preparation method of asphalt

A road and environmental protection technology, applied in building thermal insulation materials, building components, buildings and other directions, can solve the problems of high toxicity of flame retardant asphalt flame retardant, large amount of asphalt burning smoke, and high construction requirements, and achieve low price and production. The effect of low cost and high reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

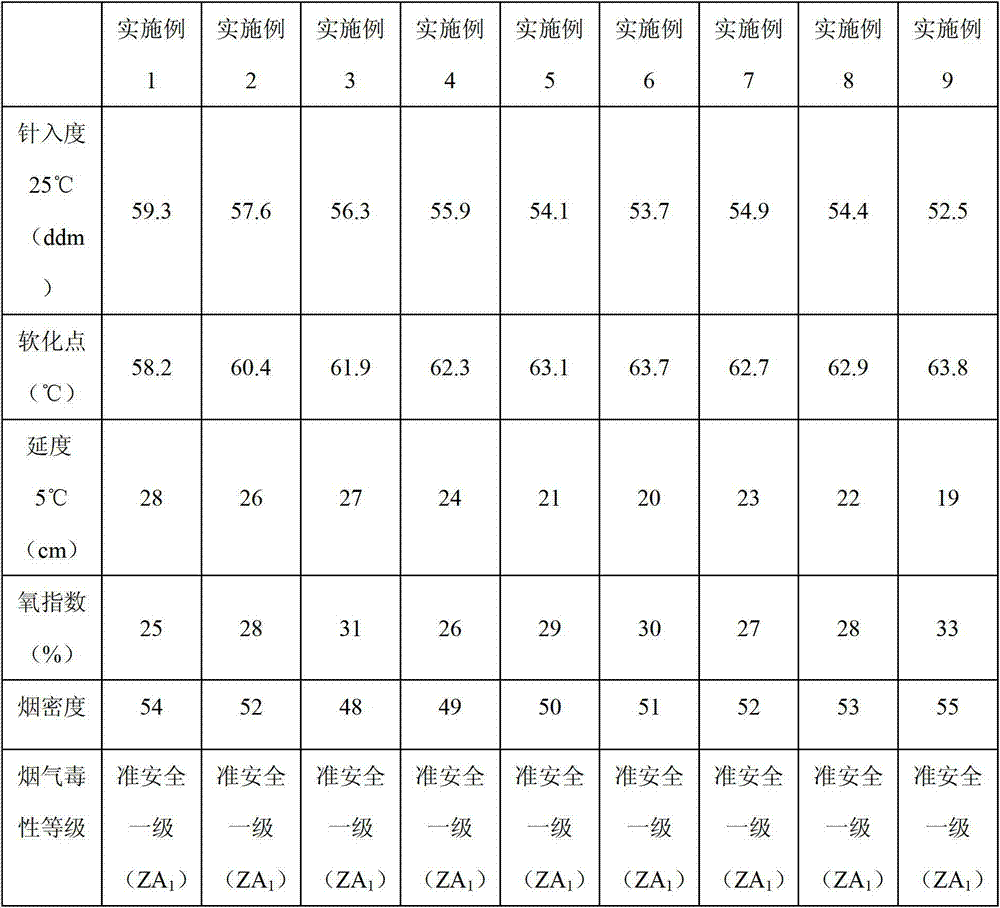

Embodiment 1

[0035] Take by weight: 100 parts of Korean SK90# asphalt; 2 parts of hydrotalcite powder; 10 parts of aluminum hydroxide; 1 part of zinc borate;

[0036] (1) Raise the temperature of the Korean SK90# asphalt to 130°C~135°C and keep it in a molten state;

[0037] (2) Add hydrotalcite powder, aluminum hydroxide and zinc borate in proportion to the molten Korean SK90# asphalt, and use a stirrer to stir evenly;

[0038] (3) Use a high-speed shearing machine to cut at a speed of 1000r / min for 10 to 15 minutes;

[0039] (4) Use a high-speed shearing machine to cut for 15-20 minutes at a speed of 5000r / min.

Embodiment 2

[0041] Take by weight: 100 parts of Korean SK90# asphalt; 4 parts of hydrotalcite powder; 15 parts of aluminum hydroxide; 1 part of silane coupling agent;

[0042] (1) Raise the temperature of the Korean SK90# asphalt to 130°C~135°C and keep it in a molten state;

[0043] (2) Add hydrotalcite powder, aluminum hydroxide and silane coupling agent in proportion to the molten Korean SK90# asphalt, and use a stirrer to stir evenly;

[0044] (3) Use a high-speed shearing machine to cut at a speed of 1000r / min for 10 to 15 minutes;

[0045] (4) Use a high-speed shearing machine to cut for 15-20 minutes at a speed of 5500r / min.

Embodiment 3

[0047] Take by weight: 100 parts of Korean SK90# asphalt; 5 parts of hydrotalcite powder; 20 parts of aluminum hydroxide; 5 parts of zinc borate; 3 parts of silane coupling agent;

[0048] (1) Raise the temperature of the Korean SK90# asphalt to 130°C~135°C and keep it in a molten state;

[0049] (2) Add hydrotalcite powder, aluminum hydroxide, zinc borate and silane coupling agent in proportion to the molten Korean SK90# asphalt, and use a stirrer to stir evenly;

[0050] (3) Use a high-speed shearing machine to cut at a speed of 1000r / min for 10 to 15 minutes;

[0051] (4) Use a high-speed shearing machine to cut for 15-20 minutes at a speed of 5500r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com