Pyrolysis and gasification method and device for preparing tar-free hydrogen-rich gas

A pyrolysis gasification, tar-free technology, used in the manufacture of combustible gas, petroleum industry, etc., can solve problems such as agglomeration and affecting the normal operation of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

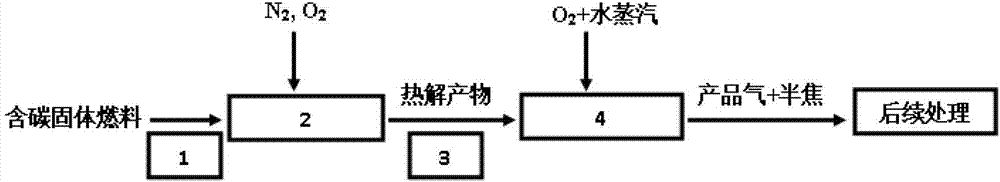

[0043] The pyrolysis gasification method for preparing tar-free hydrogen-rich gas of the present invention comprises the following steps:

[0044] 1) The carbon-containing solid raw material is sent into the upstream pyrolysis reactor through the feeding device for pyrolysis to produce pyrolysis gas phase products and solid products;

[0045] 2) The pyrolysis gas phase products and solid products produced in step 1) are passed into the downstream tar cracking reactor, and the tar is removed through high-temperature pyrolysis, partial oxidation and pyrolysis semi-coke catalytic cracking reactions to obtain pyrolysis gas and pyrolysis semi-coke. coke.

[0046] The upstream pyrolysis reactor can be a rotary kiln, a fluidized bed or a dilute phase transport bed. The above-mentioned downstream tar cracking reactor can be a rotary kiln, a dilute phase conveying bed, a settling furnace or a fixed bed.

[0047] The carbon-containing solid raw material is coal, biomass or other carbon-...

Embodiment 1

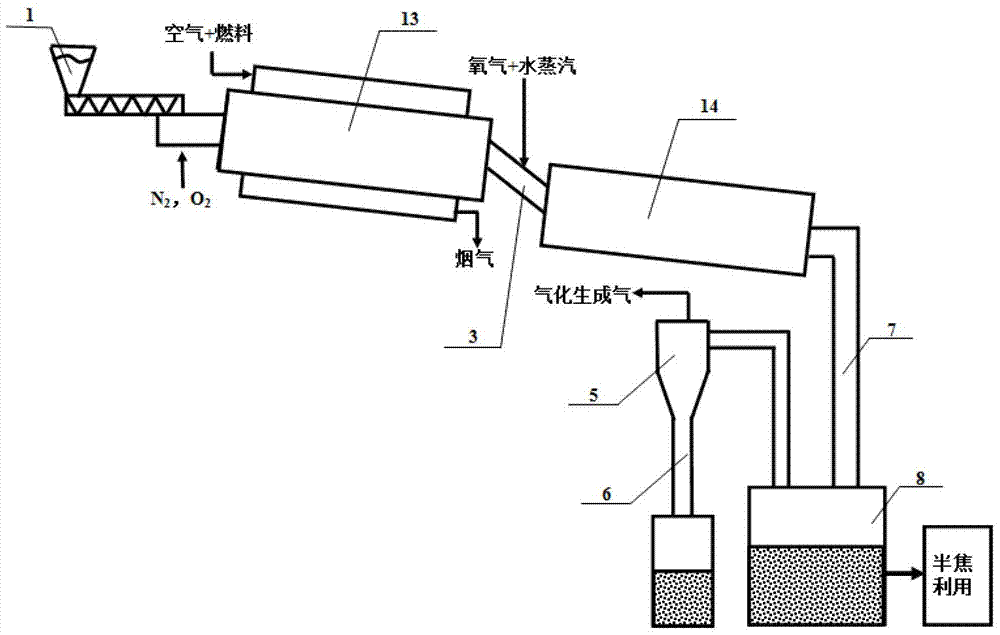

[0058] The schematic diagram of the pyrolysis gasification device combined with the two-stage rotary kiln reactor in this embodiment is as follows figure 2 As shown, it includes a feeding device 1, a first rotary kiln reactor 13, a second rotary kiln reactor 14, a coke quenching device 8, a cyclone separator 5, a dipleg 6, and the like.

[0059] When using this pyrolysis gasification device to prepare tar-free hydrogen-rich gas, carbon-containing solid fuel (such as coal) with a particle size of <20mm is sent to the upstream first rotary kiln through the feeding device 1 (such as a screw feeder) Pyrolysis is carried out at 700-900°C in the reactor 13, and the generated mixed gas and solid products enter the downstream second rotary kiln reactor 14 through the overflow pipe 3. A certain amount of oxygen, water vapor and other gases are introduced into the second rotary kiln reactor 14 and maintained at 1100°C. In the second rotary kiln reactor 14, the thermal cracking and par...

Embodiment 2

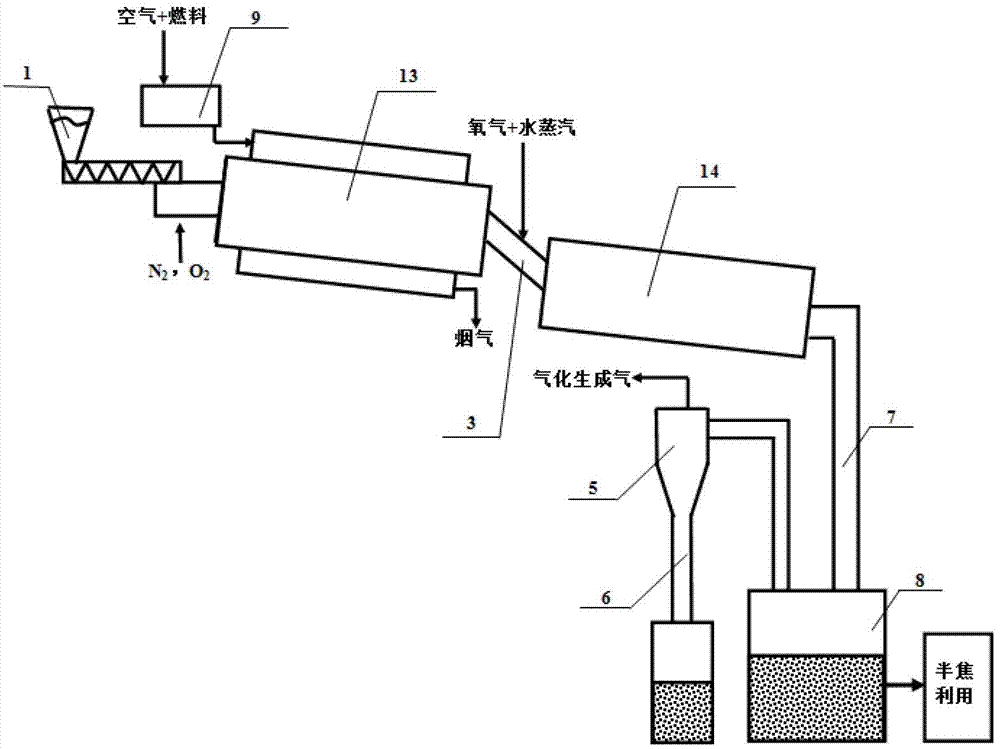

[0062] The schematic diagram of the pyrolysis gasification device of this embodiment is as follows image 3 As shown, in this embodiment, a burner 9 is added outside the upstream first rotary kiln reactor 13 described in embodiment 1, and hot flue gas is used as the heat source of the first rotary kiln reactor 13, and the others are the same as in embodiment 1. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com