Method for screening citrus fruit wine brewing saccharomycetes and method for producing citrus fruit wine

A technology of fruit wine brewing and production methods, applied in the field of bioengineering, can solve problems such as shortage, unstable product flavor, precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

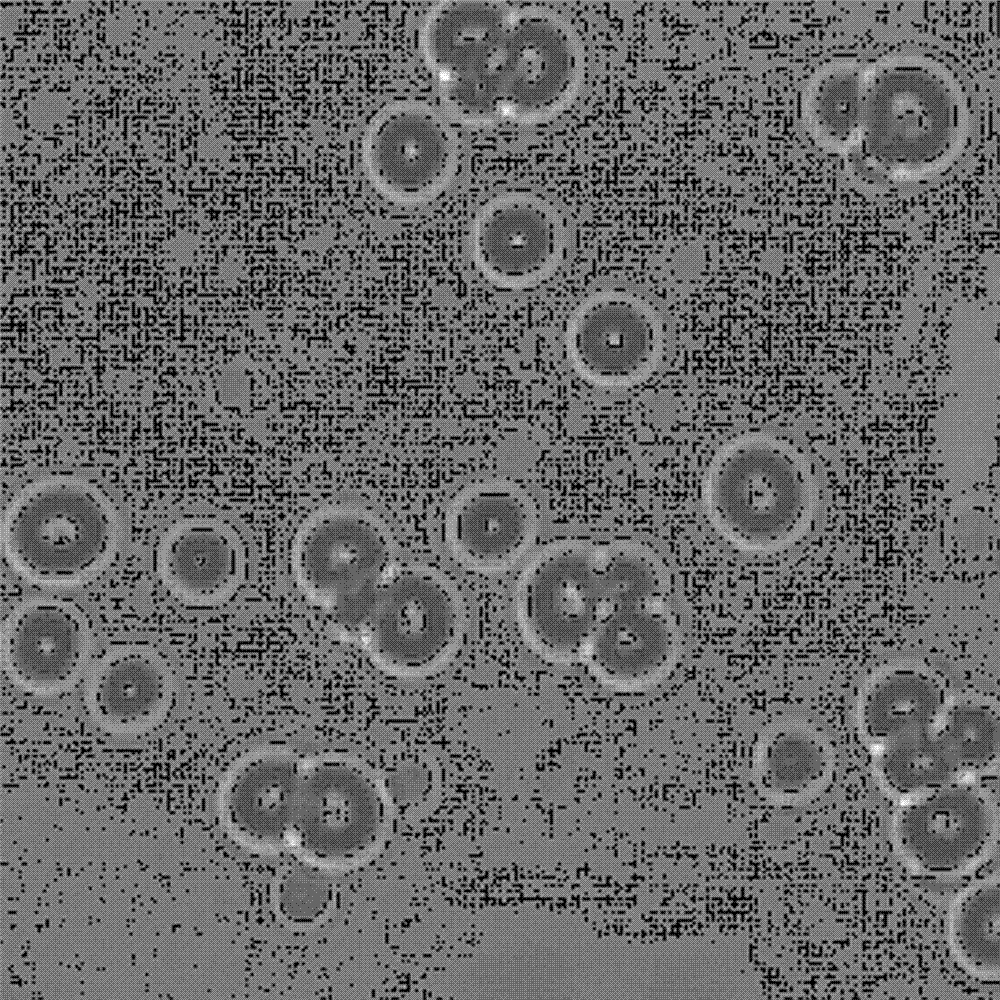

[0033] Example 1 : Isolation, purification and cultivation of yeast ZGJ-1 for high-quality fruit wine

[0034] 1. Peel wild tangerines, squeeze the juice, and put them in bottles. At a suitable temperature, the juice of tangerines can be fermented by itself, and the wine body emits fruity aroma, but the quality is unstable, and the wine has a light sour taste. It is preliminarily determined that there is Saccharomyces cerevisiae in wild tangerine.

[0035]2. Spread the yeast on a petri dish containing sterilized bean sprouts juice solid medium on a sterile operating table, and put it into a 28°C incubator for cultivation. After 3 days, it was found that in addition to yeast, there was also a small amount of mold in the culture medium. Pick the yeast and inoculate it on the reconstituted fresh medium. After culturing for 3 days, repeat the above steps until a pure yeast strain is isolated. The colony on the medium is milky white, the yeast grows well, is relatively moist,...

Embodiment 2

[0036] Example 2: Using yeast ZGJ-1 (CCTCC No: 2012472) to brew citrus fruit wine

[0037] 1. Raw material processing: 10kg of fresh citrus with high maturity and no rot is selected as raw material. Cleaning→peeling and splitting→steaming in a steamer for 3~5 minutes to passivate the enzymes in the citrus→pulp into pulp with a juicer→filter with sterilized double-layer gauze in a sterilized fermenter→get citrus pulp . Measure the total sugar content of the juice and record the result.

[0038] 2. Pectinase treatment: measure the original pH of the citrus pulp, add 0.2% pectinase, and let it stand for clarification at 50°C for 4 hours. After the clarification is complete, take the supernatant and adjust the sugar content of the citrus pulp to 20%. If reached, add white sugar to adjust.

[0039] 3. Main fermentation: In the sterilized fermentation bottle, add 5-10% (optimum 7%) of the yeast ZGJ-1 of the present invention, add potassium metabisulfite at a ratio of 60-80mg / L,...

Embodiment 3

[0041] Embodiment 3: Determination of the amount of pectinase added during citrus fruit wine brewing

[0042] 1. Choose fresh citrus with high maturity and no rot as raw material; clean → peel and split → steam in a steamer for 3-5 minutes, passivate the enzymes in citrus → use a juicer to make pulp → use sterilized citrus Double-layer gauze filter in a fermentation bottle → get citrus pulp. Measure the total sugar content of the juice and record the result.

[0043] 2. Pectinase treatment: measure the original pH of the citrus pulp, pack in sterilized fermentation bottles and number them, and add 0.1%, 0.2%, 0.3% and 0.4% pectinase respectively. Put the fermentation bottle in a 50°C incubator and let it stand for clarification for 4 hours, then take the supernatant and measure the light transmittance at a wavelength of 610nm, and record the results. The higher the light transmittance, the higher the clarity of the juice. Known from Table 1: adding 0.2% pectinase, the lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com