Amorphous carbon complex coating and preparation method thereof

A composite coating and amorphous carbon technology, applied in the field of wear-resistant coatings, can solve problems such as hardness and unsatisfactory friction and wear performance, and achieve the effects of easy promotion and utilization, improved binding force, and good binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

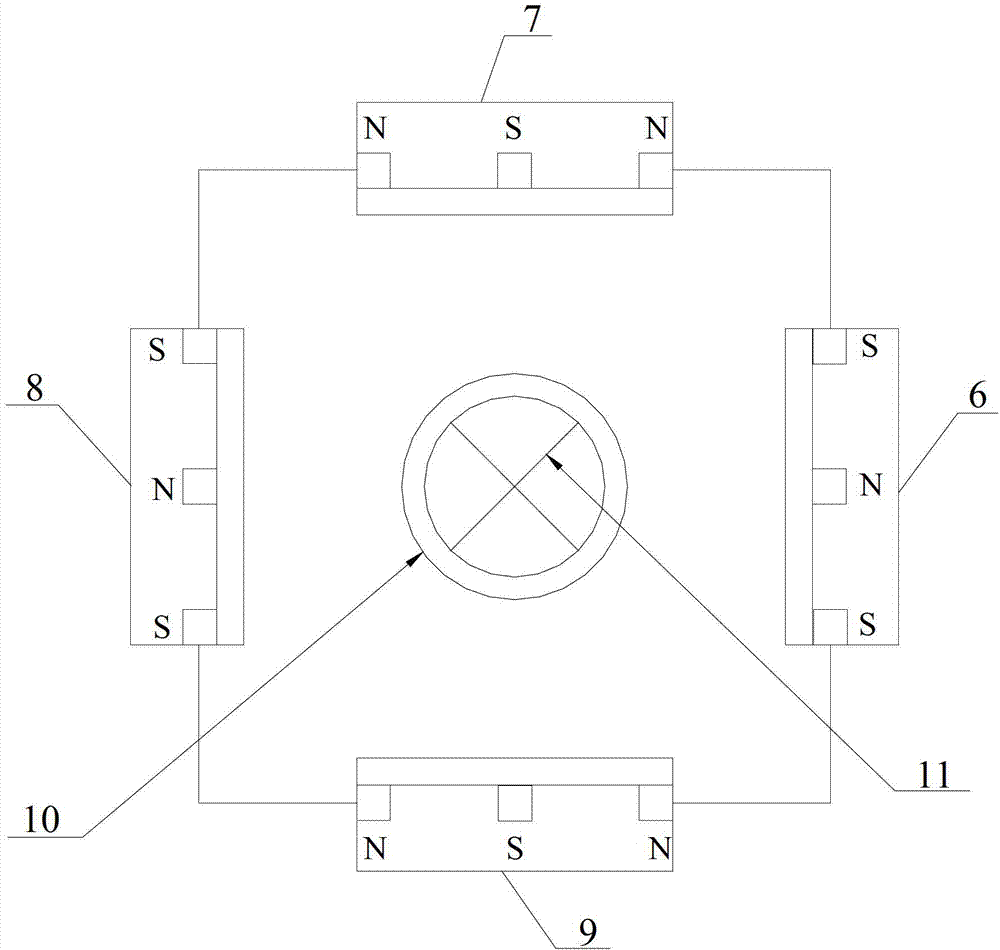

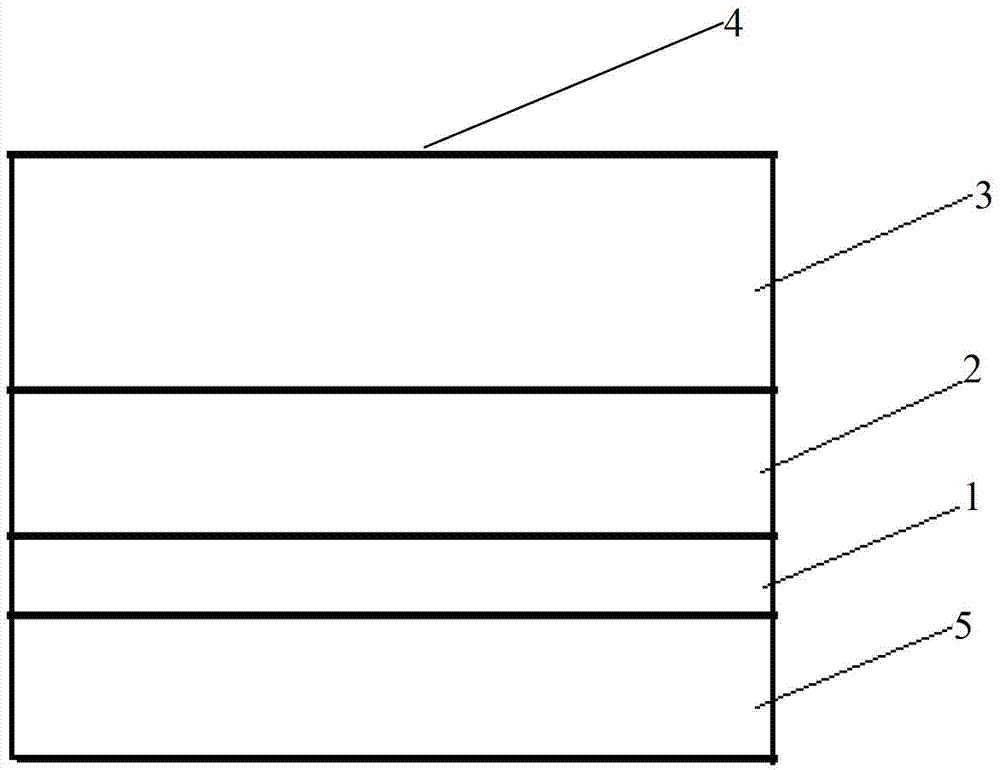

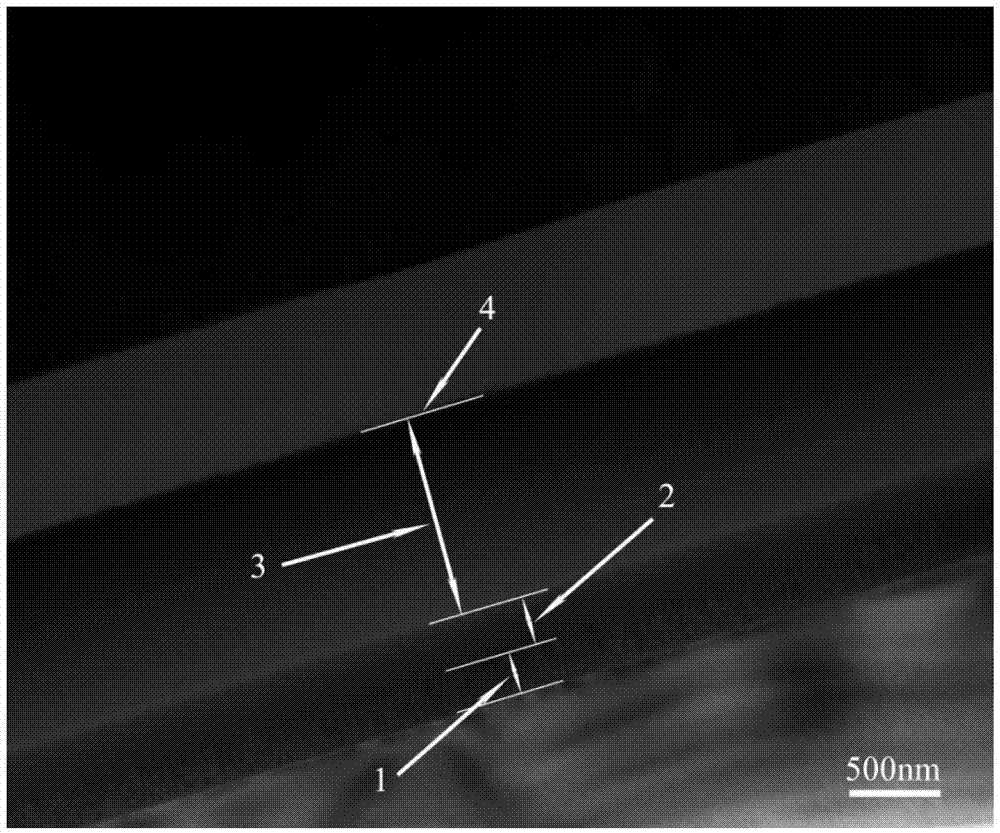

[0036] The amorphous carbon composite coating prepared by the closed-field unbalanced magnetron sputtering method adopts the device for realizing the preparation method of the amorphous carbon composite coating of the present invention in the specific embodiment, and the preparation steps are as follows:

[0037] 1) Select the medical Ti6Al4V alloy as the substrate, place the substrate on the sample holder 11 on the sample stage 10, the graphite target 6 and the graphite target 8 work, the titanium target 7 works, the titanium target 9 does not work, adjust the relationship between each target and the substrate The spacing is adjusted by 10cm, and the rotational speed of the sample stage 10 is controlled to be 3rpm;

[0038] Pre-evacuate the chamber to 4.5 x 10 -4 Pa, followed by pure argon gas, the flow rate of argon gas was controlled at 25 sccm, and the pre-sputtering was performed for 30 min at a bias voltage of -500V and a titanium target current of 0.2A and a graphite ta...

Embodiment 2

[0046] The amorphous carbon composite coating prepared by the closed-field unbalanced magnetron sputtering method adopts the device for realizing the preparation method of the amorphous carbon composite coating of the present invention in the specific embodiment, and the preparation steps are as follows:

[0047] 1) Select the medical Ti6Al4V alloy as the substrate, place the substrate on the sample holder 11 on the sample stage 10, the graphite target 6 and the graphite target 8 work, the titanium target 7 works, the titanium target 9 does not work, adjust the relationship between each target and the substrate The spacing is adjusted by 10cm, and the rotational speed of the sample stage 10 is controlled to be 3rpm;

[0048] Pre-evacuate the chamber to 4.5 x 10 -4 Pa, followed by pure argon gas, the flow rate of argon gas was controlled at 25 sccm, and the pre-sputtering was performed for 30 min at a bias voltage of -500V and a titanium target current of 0.2A and a graphite ta...

Embodiment 3

[0056] The amorphous carbon composite coating prepared by the closed-field unbalanced magnetron sputtering method adopts the device for realizing the preparation method of the amorphous carbon composite coating of the present invention in the specific embodiment, and the preparation steps are as follows:

[0057] 1) Select the medical Ti6Al4V alloy as the substrate, place the substrate on the sample holder 11 on the sample stage 10, the graphite target 6 and the graphite target 8 work, the titanium target 7 works, the titanium target 9 does not work, adjust the relationship between each target and the substrate The spacing is adjusted by 10cm, and the rotational speed of the sample stage 10 is controlled to be 3rpm;

[0058] Pre-evacuate the chamber to 4.5 x 10 -4 Pa, followed by pure argon gas, the flow rate of argon gas was controlled at 25 sccm, and the pre-sputtering was performed for 30 min at a bias voltage of 500V and a titanium target current of 0.2A and a graphite tar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com