Double-crucible induction heating furnace

A technology of induction heating furnace and double crucible, which is applied in the direction of crucible furnace, lighting and heating equipment, furnace, etc., can solve the problems of raw material pollution, easy perforation, etc., and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

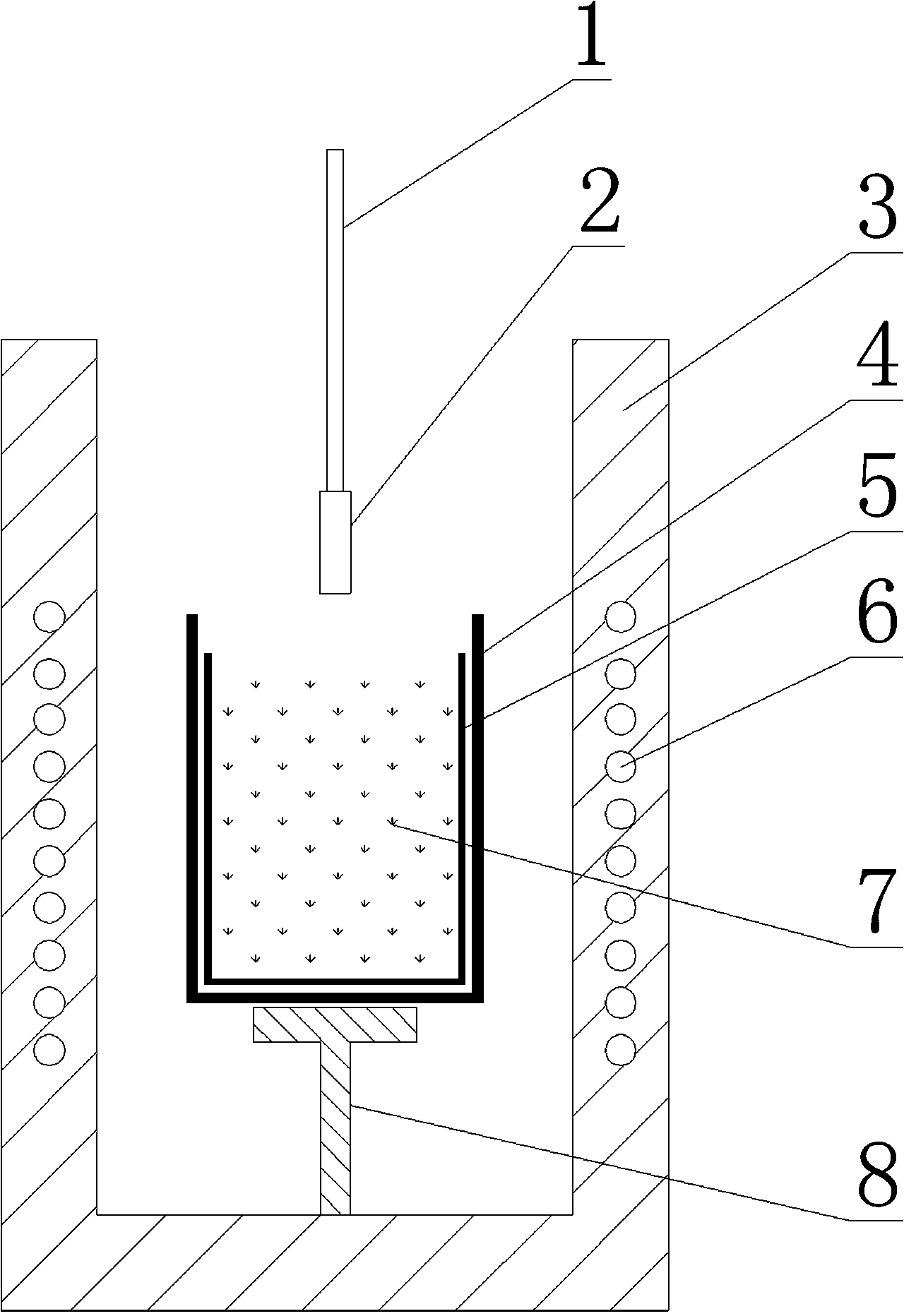

[0027] Embodiment 1: use tungsten crucible and iridium crucible cover to grow sapphire crystal (reference figure 1 ).

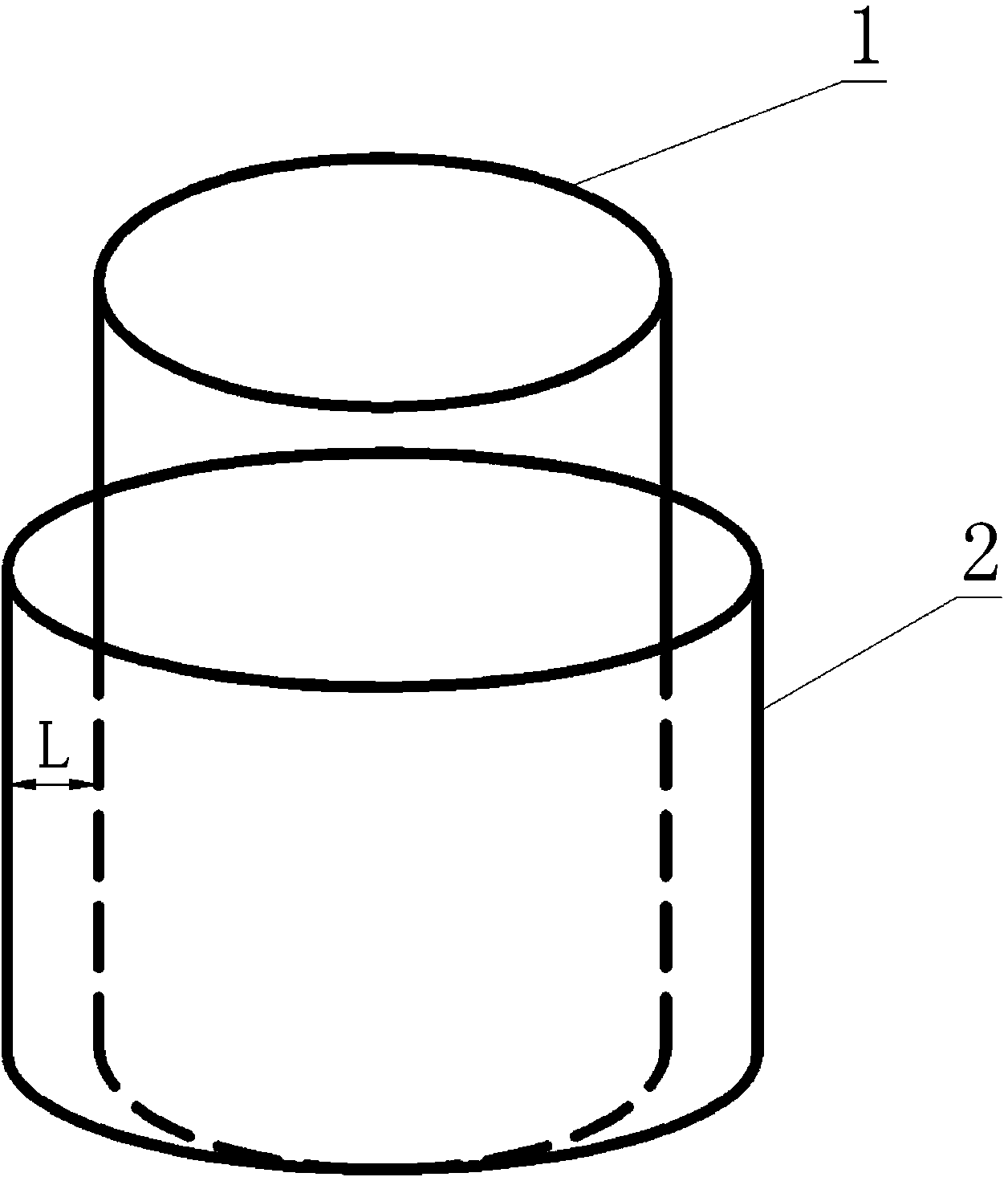

[0028] A tungsten crucible is used as the outer crucible 4 and an iridium crucible is used as the inner crucible 5 . First put the cleaned outer crucible 4 on the crucible support frame 8 of the intermediate frequency induction heating furnace, then put the cleaned inner crucible 5 into the outer crucible 4, and the center lines of the two crucibles and the center line of the heating furnace are in a straight line Above, the gap between the crucible walls is 1-15mm, the height of the outer crucible 4 and the inner crucible 5 are the same, the wall thickness of the outer crucible 4 is 5-10mm, and the wall thickness of the inner crucible 5 is 3-8mm.

[0029] Put 30kg of clean aluminum oxide raw material 7 into the inner crucible 5, install the sapphire seed crystal 2 on the lifting rod 1 and adjust the verticality, and finally cover and seal the furnace.

[...

Embodiment 2

[0033] Embodiment 2: use graphite crucible and platinum-rhodium crucible cover to grow lithium cholate crystal (reference figure 1 ).

[0034] A graphite crucible is used as the outer crucible 4, and a platinum-rhodium crucible is used as the inner crucible 5. Install the inner and outer crucibles as in the process of embodiment 1, the gap between the two crucible walls is 1-10mm, the height of the outer crucible 4 is 1 / 2 of the inner crucible 5, the wall thickness of the outer crucible 4 is 2-10mm, and the inner crucible 5 wall thickness 3-10mm.

[0035] Put 10 kg of clean lithium cholate raw material 7 into the inner crucible 5, install the lithium cholate seed crystal 2 on the lifting rod 1 and adjust the verticality, and finally cover and seal the furnace.

[0036] The air in the furnace was extracted as in the process of Example 1, and then filled with argon to keep the slight positive pressure in the furnace all the time.

[0037] Turn on the heating power supply, ra...

Embodiment 3

[0039] Embodiment 3: cover with molybdenum crucible and corundum crucible melting nickel-titanium alloy (reference figure 1 ).

[0040]A molybdenum crucible is used as the outer crucible 4, and a corundum crucible is used as the inner crucible 5. Install the inner and outer crucibles as in the process of Example 1, the gap between the two crucible walls is 5-15mm, the height of the outer crucible 4 is 1.5 times that of the inner crucible 5, the wall thickness of the outer crucible 4 is 3-6mm, and the inner crucible 5 walls 3-10mm thick.

[0041] Mix 5kg of high-purity nickel and 5kg of high-purity titanium evenly and put them into the inner crucible, cover and seal the furnace. Vacuumize and maintain the vacuum in the furnace within 0.01pa.

[0042] Turn on the heating power supply to melt the raw materials slowly (about 1450°C), then slowly cool down until the power of the induction coil 6 drops to 0, turn off the heating power supply, and after the furnace cools down to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com