Preserved plum powder tabletting candy produced by directly tabletting complete powder, and preparation method

A technology for tableting candy and full powder, which is applied in the fields of confectionary, application, confectionary industry, etc. It can solve the problems of unsuitable powder, poor fluidity and compressibility, etc., and achieve improved powder characteristics, uniform shape and composition Consistent, improved overall powder properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

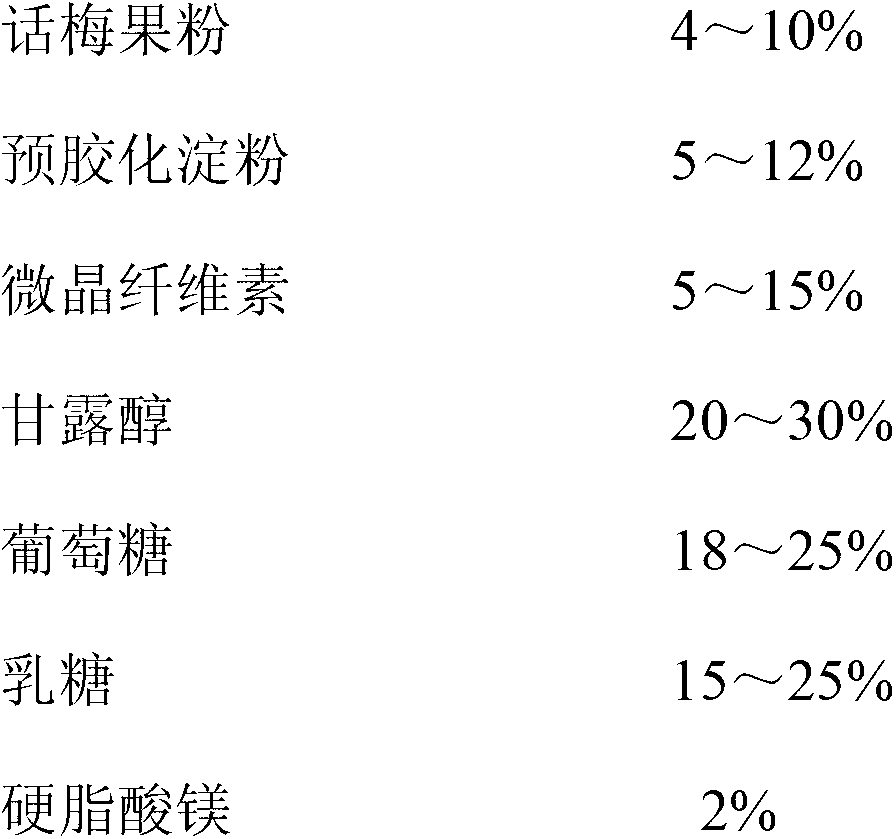

Method used

Image

Examples

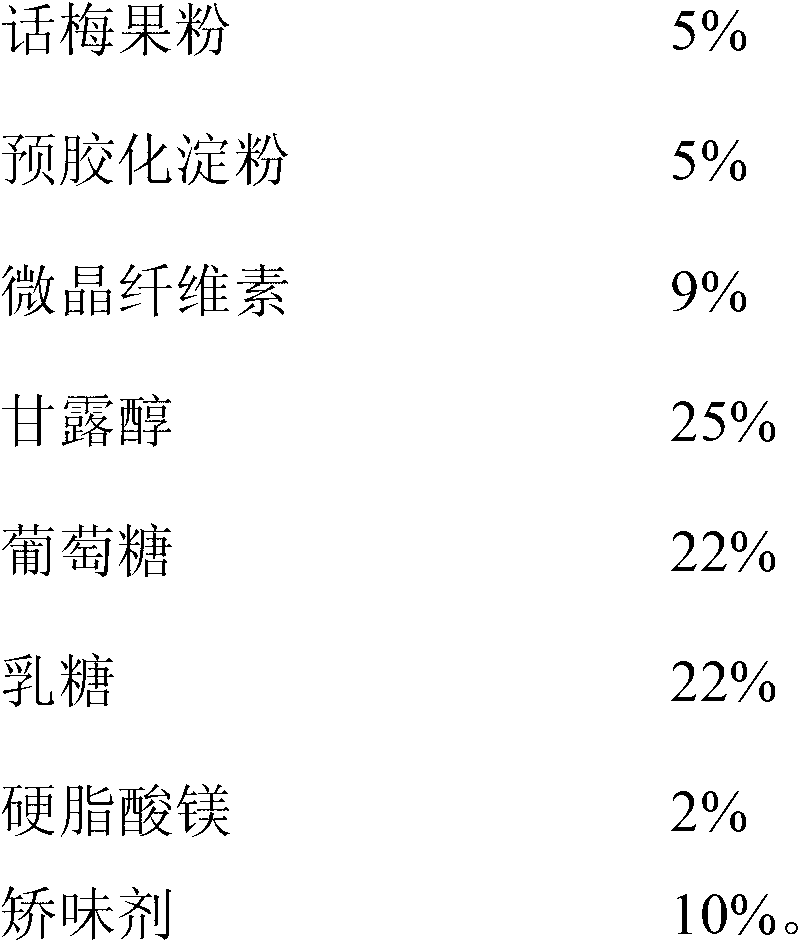

Embodiment 1

[0029] In this example, the plum fruit powder compressed tablet candy is prepared from the following raw materials by weight percentage: plum fruit powder 5.00%; pregelatinized starch 5.00%; microcrystalline cellulose 9.00%; mannitol 25.00%; lactose 22.00%; Glucose 22.00%; Menthol 9.00%; Magnesium Stearate 2%; Citric Acid and Malic Acid 0.3% each, Acesulfame K and Sucralose 0.2% each

[0030] The preparation method follows the steps below:

[0031] (1) Pretreatment: pass the plum fruit powder, pregelatinized starch, microcrystalline cellulose, mannitol, glucose, lactose, flavoring agent and magnesium stearate through an 80-mesh sieve, and set aside;

[0032] (2) Pre-mixing: Weigh the plum fruit powder, pregelatinized starch, microcrystalline cellulose, mannitol, glucose and lactose to mix the formula, then weigh the flavoring agent in the formula, add it to the mixer for pre-mixing ;

[0033] (3) Total blending: adding magnesium stearate to the premixed material for mixing; ...

Embodiment 2

[0038] In this example, the plum fruit powder tablet candy is prepared from the following raw materials by weight percentage: plum fruit powder 5.00%; pregelatinized starch 10%; microcrystalline cellulose 10%; mannitol 21.00% lactose 21.00%; glucose 21.00%; menthol 9.00%; magnesium stearate 2%; 0.3% each of citric acid and malic acid, 0.2% each of acesulfame potassium and sucralose

[0039] The preparation method follows the steps below:

[0040] (1) Pretreatment: pass the plum fruit powder, pregelatinized starch, microcrystalline cellulose, mannitol, glucose, lactose, flavoring agent and magnesium stearate through a 100-mesh sieve, and set aside;

[0041] (2) Pre-mixing: Weigh the plum fruit powder, pregelatinized starch, microcrystalline cellulose, mannitol, glucose and lactose to mix the formula, then weigh the flavoring agent in the formula, add it to the mixer for pre-mixing ;

[0042] (3) Total blending: adding magnesium stearate to the premixed material for mixing;

...

Embodiment 3

[0047] In this example, the plum fruit powder compressed tablet candy is prepared from the following raw materials by weight percentage: plum fruit powder 4.00%; pregelatinized starch 12.00%; microcrystalline cellulose 5.00%; mannitol 21.50%; lactose 21.50%; Glucose 24.00%; Menthol 9.00%; Magnesium Stearate 2%; Citric Acid and Malic Acid 0.3% each, Acesulfame K and Sucralose 0.2% each

[0048] The preparation method follows the steps below:

[0049] (1) Pretreatment: pass the plum fruit powder, pregelatinized starch, microcrystalline cellulose, mannitol, glucose, lactose, flavoring agent and magnesium stearate through a 90-mesh sieve, and set aside;

[0050](2) Pre-mixing: Weigh the plum fruit powder, pregelatinized starch, microcrystalline cellulose, mannitol, glucose and lactose to mix the formula, then weigh the flavoring agent in the formula, add it to the mixer for pre-mixing ;

[0051] (3) Total blending: adding magnesium stearate to the premixed material for mixing; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com