High-efficient needle punched filter felt for purifying Pm 2.5 fine particles and manufacturing method thereof

A technology of fine particles and manufacturing methods, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of low cost and achieve the effects of improving wear resistance, air permeability, and high temperature resistant chemical fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 (manufacturing 100 square meters of needle felts)

[0031] The intermediate chemical fiber base cloth layer is made of PTFE fiber, the specification is 150g / m 2 .

[0032] The face yarn is made of ultra-fine E-glass fiber and ultra-fine PTFE fiber. Among them, the amount of E glass fiber accounts for 70%, and PTFE accounts for 30%. The dosage is 42Kg and 18Kg respectively. The face layer yarn is made by conventional production process. Its specification is 600g / m 2 .

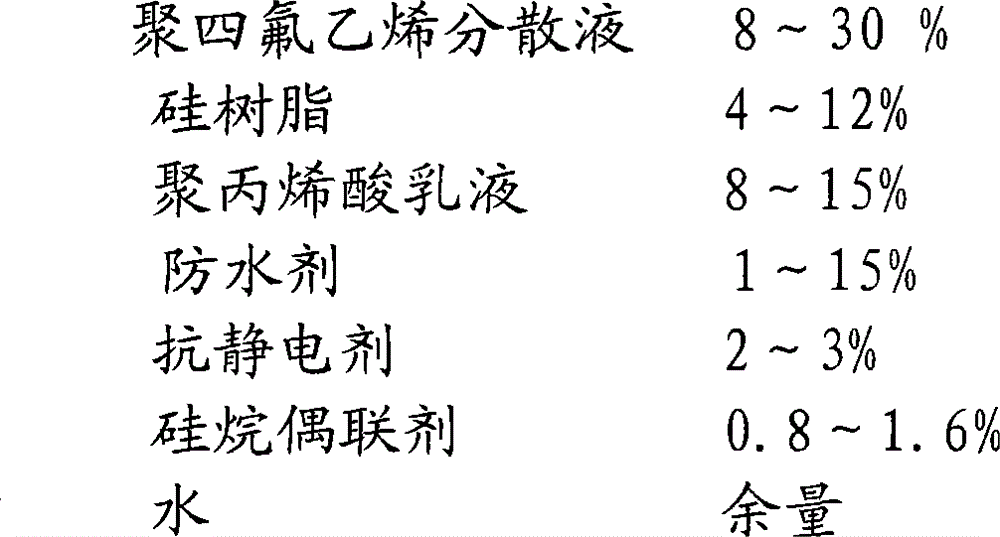

[0033] The inner layer yarn is made of E glass fiber and PTEF ordinary chemical fiber material, and its specifications are 5-7um and 10um respectively. PTEF chemical fiber accounts for 70%, E glass fiber accounts for 30%. Made into inner yarn. Its specification is 600g / m 2 . Then use the conventional needle punching process to make the surface layer yarn, the inner layer yarn and the intermediate chemical fiber base cloth into a plain felt. The finished plain felt is then chemicall...

Embodiment 2

[0035] The intermediate chemical fiber base cloth layer is made of PTFE fiber, the specification is 150g / m 2 .

[0036] The surface yarn is made of ultra-fine E glass fiber, and its specification is 600g / m 2 .

[0037] The inner yarn is made of E glass fiber and chemical fiber material, PTEF chemical fiber accounts for 70%, E glass fiber accounts for 30%. The two fiber specifications are 7um and 10um respectively. Made into inner yarn. Its specification is 600 / m 2 . , and then use the conventional acupuncture process to make plain felt. The finished plain felt is then chemically treated. The compounding method of chemical treatment agent is identical with embodiment 1. Then dry it. Hot press calendering treatment. Process is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com