Method for forming ZnS/SnS/CuA core-shell structure composite powder through thermosynthesis of normal pressure solvent

A core-shell structure, composite powder technology, applied in chemical instruments and methods, tin compounds, microcapsule preparations, etc., can solve the problems of slow reaction speed, harshness, difficult controllable synthesis of core-shell, etc. The effect of low cost and strong controllability of the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

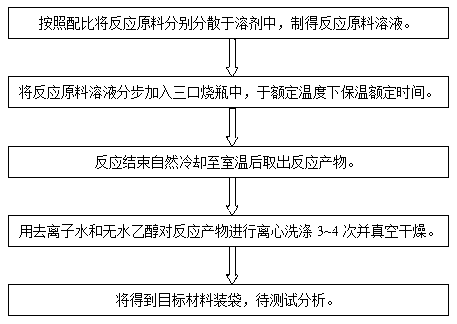

Method used

Image

Examples

Embodiment 1

[0027] (1) Take by weighing 2.7375 grams of zinc acetate, 2.8206 grams of stannous chloride, 2.8549 grams of thiourea, 4.9913 grams of copper acetate and 2.961 grams of selenium powder, wherein zinc acetate, stannous chloride, thiourea and copper acetate are respectively dissolved in ethylene glycol to obtain a solution, and the selenium powder is dissolved in hydrazine hydrate to obtain a solution.

[0028] (2) Add the ethylene glycol solution of zinc acetate prepared in step (1) and the ethylene glycol solution of thiourea into a three-necked flask and mix them, then add 5 milliliters of ethylenediamine, and place the three-necked flask in a magnetic stirring oil bath , and the three bottle mouths were respectively inserted with sealing plugs, condenser tubes and thermometers, heated while stirring, and kept at 150°C for 1 hour, then naturally cooled to room temperature to prepare a solution containing ZnS nanopowder.

[0029] (3) Add the ethylene glycol solution of the tin ...

Embodiment 2

[0033] (1) Take by weighing 0.5488 gram of zinc acetate, 0.5641 gram of stannous chloride, 0.3806 gram of thiourea, 0.9983 gram of copper acetate and 0.3806 grams of thiourea, wherein zinc acetate, stannous chloride, copper acetate and two parts of thiourea are dissolved in ethylene glycol respectively to obtain a solution, and the ethylene glycol solutions of two parts of thiourea are respectively marked a (containing 0.3806 grams of thiourea) , b (containing 0.3806 grams of thiourea).

[0034] (2) The ethylene glycol solution of zinc acetate prepared in step (1) and the ethylene glycol solution of No. a thiourea are added in a three-necked flask and mixed, and the three-necked flask is placed in a magnetic stirring oil bath, and three bottles Insert a sealing plug, a condenser tube and a thermometer into the mouth respectively, stir while heating, keep warm at 150°C for 1 hour, and cool naturally to room temperature to prepare a solution containing ZnS nanopowder.

[0035] ...

Embodiment 3

[0039] (1) Take by weighing 0.5488 gram of zinc acetate, 0.5641 gram of stannous chloride, 0.5709 gram of thiourea, 0.9983 gram of copper acetate and 0.5709 grams of thiourea, wherein zinc acetate, stannous chloride, copper acetate and two parts of thiourea are dissolved in ethylene glycol respectively to obtain a solution, and the ethylene glycol solutions of two parts of thiourea are respectively labeled a (containing 0.5709 grams of thiourea) , b (containing 0.5709 grams of thiourea).

[0040](2) The ethylene glycol solution of zinc acetate prepared in step (1) and the ethylene glycol solution of No. a thiourea are added in a three-necked flask and mixed, and the three-necked flask is placed in a magnetic stirring oil bath, and three bottles Insert a sealing plug, a condenser tube and a thermometer into the mouth respectively, stir while heating, keep warm at 150°C for 1 hour, and cool naturally to room temperature to prepare a solution containing ZnS nanopowder.

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com