Rare earth complex and preparation method thereof, rare earth catalyst system and preparation method of butadiene-isoprene copolymer

A technology of rare earth complexes and rare earth compounds, applied in chemical instruments and methods, compounds containing elements of group 3/13 of the periodic table, organic chemistry, etc., can solve problems such as equipment corrosion and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

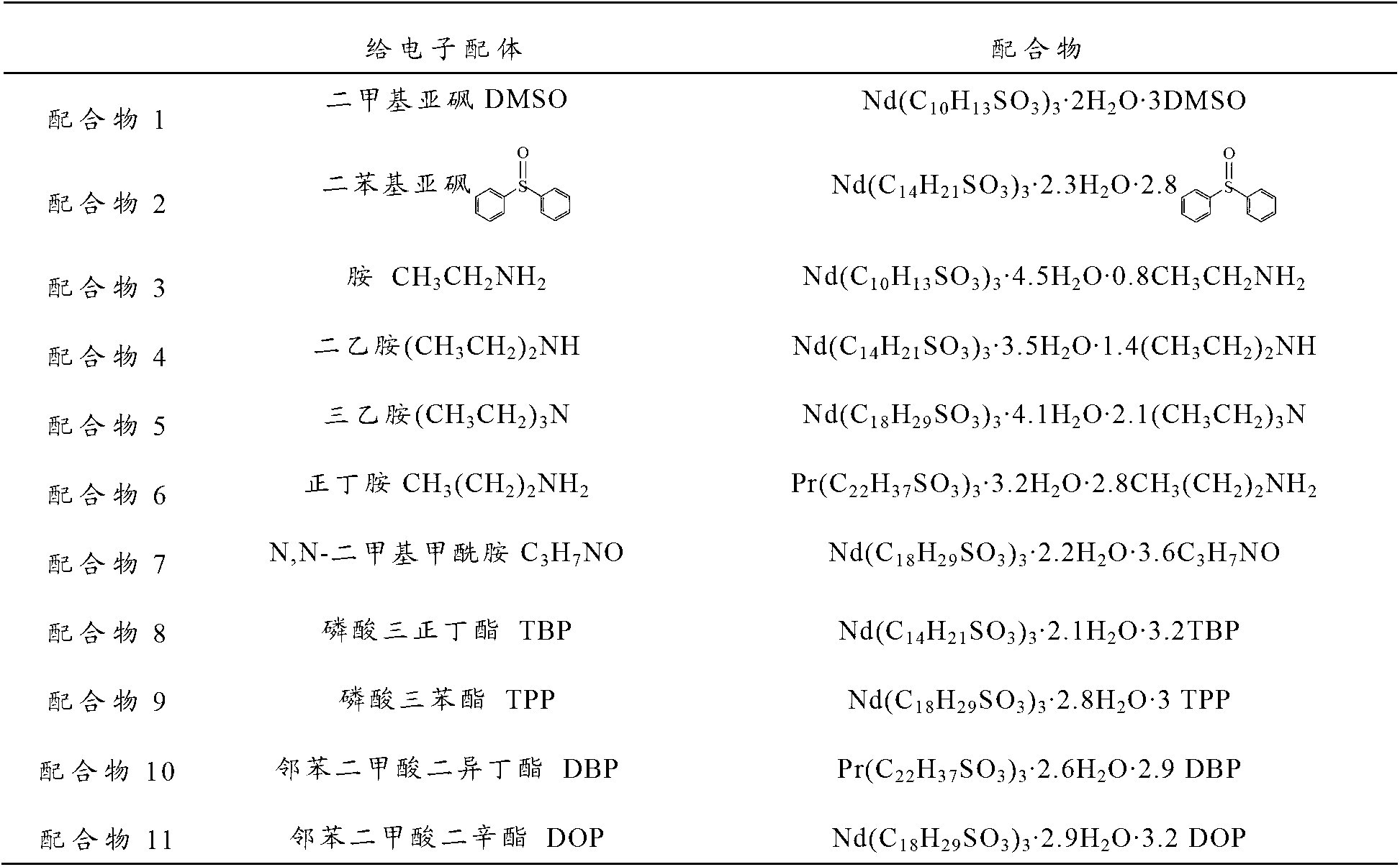

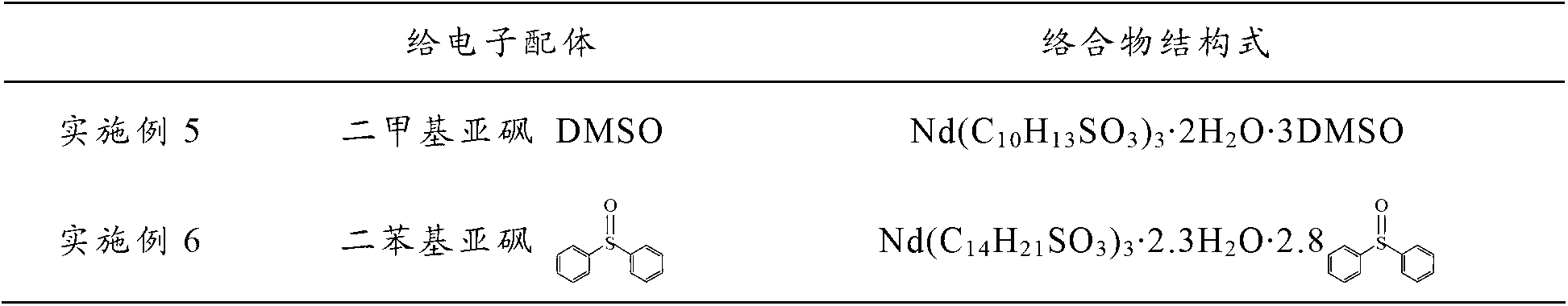

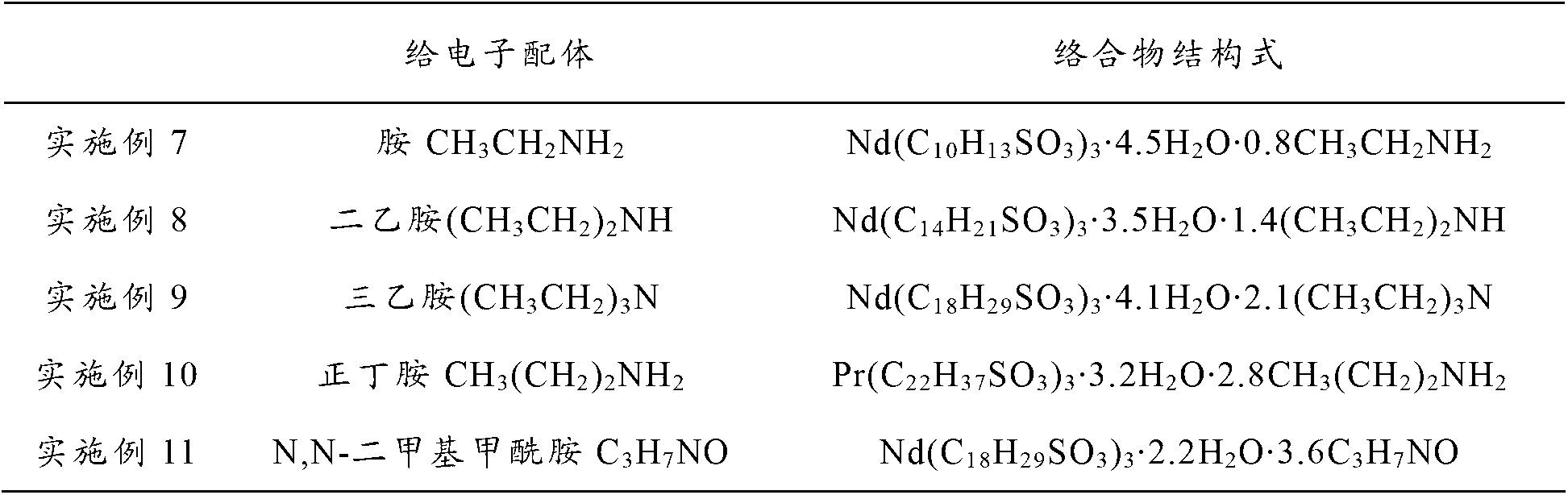

Examples

preparation example Construction

[0034] The present invention also provides a preparation method of the rare earth complex represented by formula (I), including the following steps:

[0035] Mixing rare earth oxide with alkyl benzene sulfonic acid, heating, and obtaining alkyl benzene sulfonic acid rare earth compound after reaction;

[0036] The alkylbenzene sulfonate rare earth compound and the electron donating ligand are dissolved in a solvent, and the rare earth complex as described in formula (I) is obtained after the reaction; the electron donating ligand and the alkylbenzene sulfonic acid rare earth compound are The molar ratio of rare earth elements is (3~10):1.

[0037] According to the present invention, the molar ratio of the rare earth oxide to the alkylbenzene sulfonic acid is preferably 10:1. In the process of obtaining the alkylbenzene sulfonic acid rare earth compound, the heating temperature is preferably 50-80°C, more preferably 60-70°C, and the reaction time is preferably 5-10h, more preferably ...

Embodiment 1

[0050] Example 1: Neodymium tetraalkylbenzene sulfonate Nd(C 10 H 13 SO 3 ) 3 Compound preparation

[0051] In the reactor, add neodymium oxide to the tetraalkylbenzene sulfonic acid solution at a ratio of 10:1 in the molar ratio of neodymium oxide to tetraalkylbenzene sulfonic acid, heat to 80°C under stirring, react for 8 hours, and filter , The unreacted neodymium oxide is removed and concentrated to obtain an aqueous solution of neodymium tetraalkylbenzenesulfonate compound, and then the concentrated solution is placed at room temperature to naturally precipitate crystals, which are tetraalkylbenzenesulfonate rare earth compounds with crystal water.

Embodiment 2

[0052] Example 2: Neodymium octaalkylbenzene sulfonate Nd(C 14 H 21 SO 3 ) 3 Compound preparation

[0053] In the reactor, add neodymium oxide to the octaalkylbenzene sulfonic acid solution in a ratio of 10:1 molar ratio of neodymium oxide to octaalkylbenzene sulfonic acid, and heat to 70°C under stirring, react for 6 hours, and filter , Remove the unreacted neodymium oxide, concentrate to obtain an aqueous solution of neodymium octaalkylbenzenesulfonate compound, and then place the concentrated solution at room temperature to naturally precipitate crystals, which are rare earth octaalkylbenzenesulfonate compounds with crystal water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com