Preparation method of water soluble styrene-acrylic acid solid resin used for aluminium foil coating

A technology of solid resin and styrene, applied in coating and other directions, can solve the problems such as the preparation method of styrene-acrylic solid resin has not yet been found, and achieve the effects of curbing pollution behavior, good adhesion and mild reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

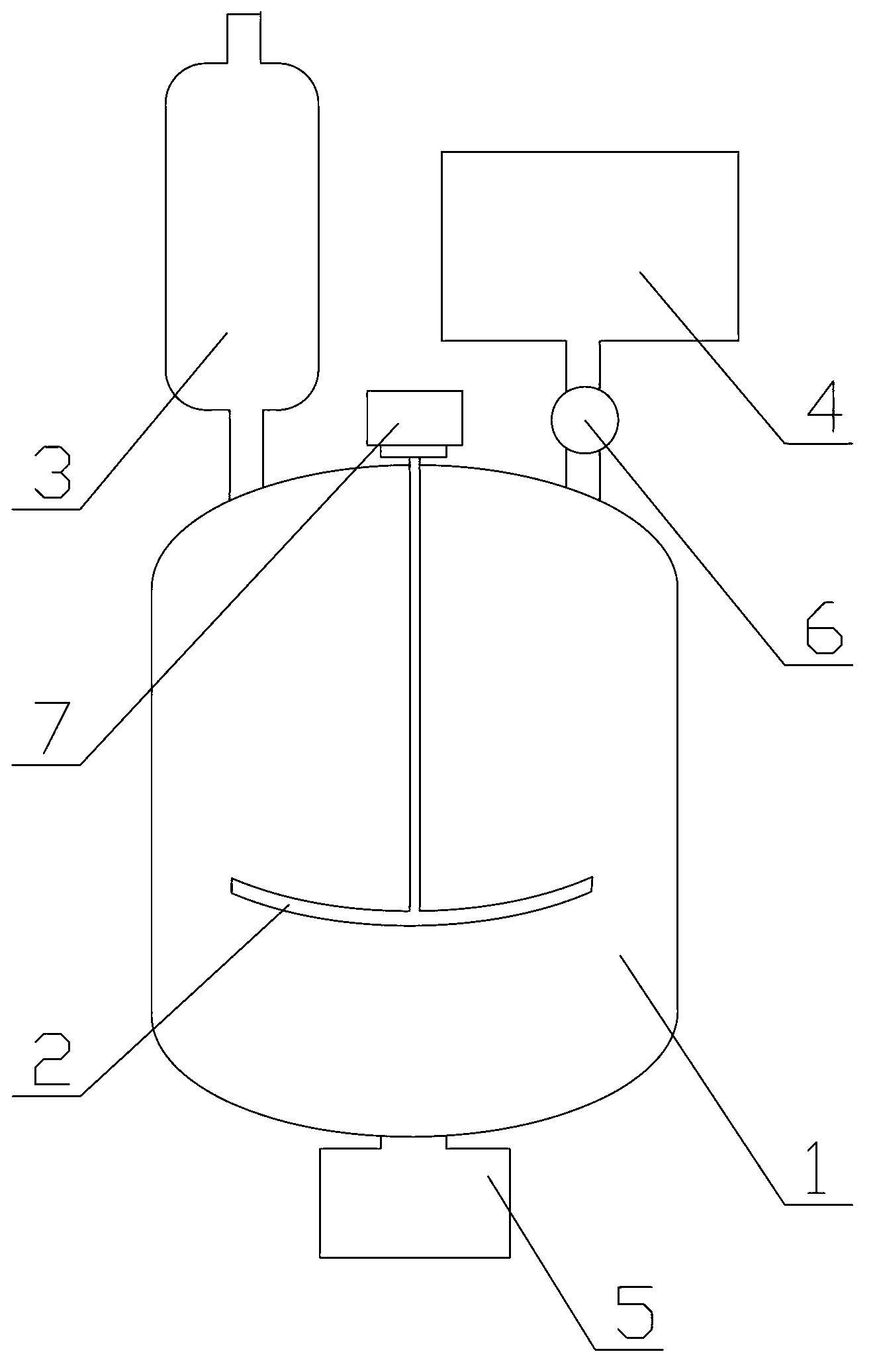

[0036] to combine figure 1, the preparation method of water-soluble styrene-acrylic acid solid resin of present embodiment aluminum foil coating comprises the following steps:

[0037] Step 1, take 5 parts of aliphatic carboxylic acid and 5 parts of ethanol by weight, then stir the weighed aliphatic carboxylic acid and ethanol evenly to obtain ethanol solution of aliphatic carboxylic acid;

[0038] Step 2, take by weight 15 parts of aliphatic vinyl unsaturated monomers, 21 parts of aliphatic unsaturated carboxylic acid monomers, 1.5 parts of chain transfer agents, 0.5 parts of initiators, 2 parts of ester solvents, and then weigh The taken aliphatic ethylenically unsaturated monomers, aliphatic unsaturated carboxylic acid monomers, chain transfer agents, initiators and ester solvents are added to the batching tank 4 and stirred evenly to obtain the first pretreatment liquid;

[0039] Step 3: Weigh 14 parts of the ester solvent by weight, then add the weighed ester solvent int...

Embodiment 2

[0046] combine figure 1 , the preparation method of water-soluble styrene-acrylic acid solid resin of present embodiment aluminum foil coating comprises the following steps:

[0047] Step 1, take by weight 4.5 parts of aliphatic carboxylic acid and 5.5 parts of ethanol, then stir the weighed aliphatic carboxylic acid and ethanol evenly to obtain an ethanol solution of aliphatic carboxylic acid;

[0048] Step 2, take by weight 18 parts of aliphatic vinyl unsaturated monomers, 20 parts of aliphatic unsaturated carboxylic acid monomers, 1.5 parts of chain transfer agents, 0.1 parts of initiators, 1.8 parts of ester solvents, and then weigh The taken aliphatic ethylenically unsaturated monomers, aliphatic unsaturated carboxylic acid monomers, chain transfer agents, initiators and ester solvents are added to the batching tank 4 and stirred evenly to obtain the first pretreatment liquid;

[0049] Step 3: Weigh 11.85 parts of the ester solvent by weight, then add the weighed ester s...

Embodiment 3

[0055] combine figure 1 , the preparation method of water-soluble styrene-acrylic acid solid resin of present embodiment aluminum foil coating comprises the following steps:

[0056] Step 1, take 5.5 parts of aliphatic carboxylic acid and 4.5 parts of ethanol by weight, then stir the weighed aliphatic carboxylic acid and ethanol evenly to obtain an ethanol solution of aliphatic carboxylic acid;

[0057] Step 2, take by weight 20 parts of aliphatic vinyl unsaturated monomers, 20 parts of aliphatic unsaturated carboxylic acid monomers, 0.7 parts of chain transfer agents, 0.3 parts of initiators, 1.5 parts of ester solvents, and then weigh The taken aliphatic ethylenically unsaturated monomers, aliphatic unsaturated carboxylic acid monomers, chain transfer agents, initiators and ester solvents are added to the batching tank 4 and stirred evenly to obtain the first pretreatment liquid;

[0058] Step 3: Weigh 10.5 parts of the ester solvent by weight, then add the weighed ester so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com