Aqueous polyurethane emulsion as well as application thereof on electrophoretic display coating liquid and display device

A water-based polyurethane and electrophoretic display technology, applied in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, coatings, etc., can solve the problems of weak adhesive viscosity, poor photoelectric performance, and low volume resistivity, etc., to achieve Improve the tensile strength and cohesion, good viscosity and film strength, improve the effect of volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

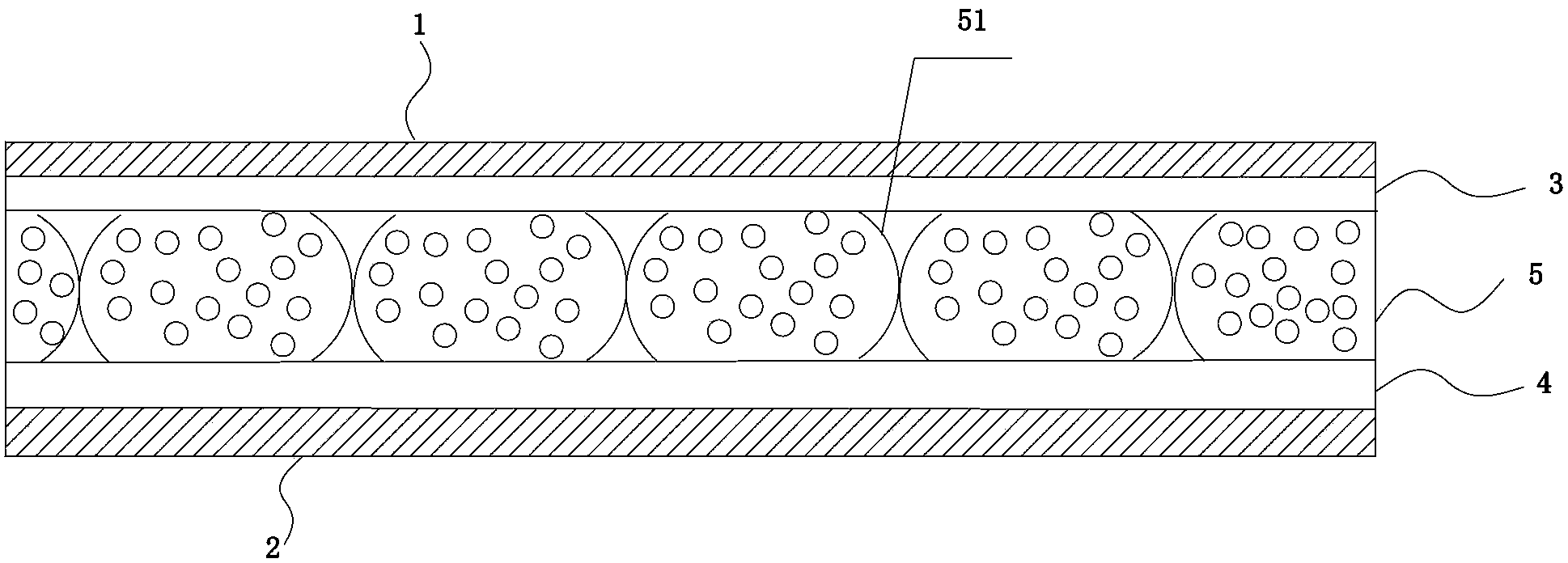

Image

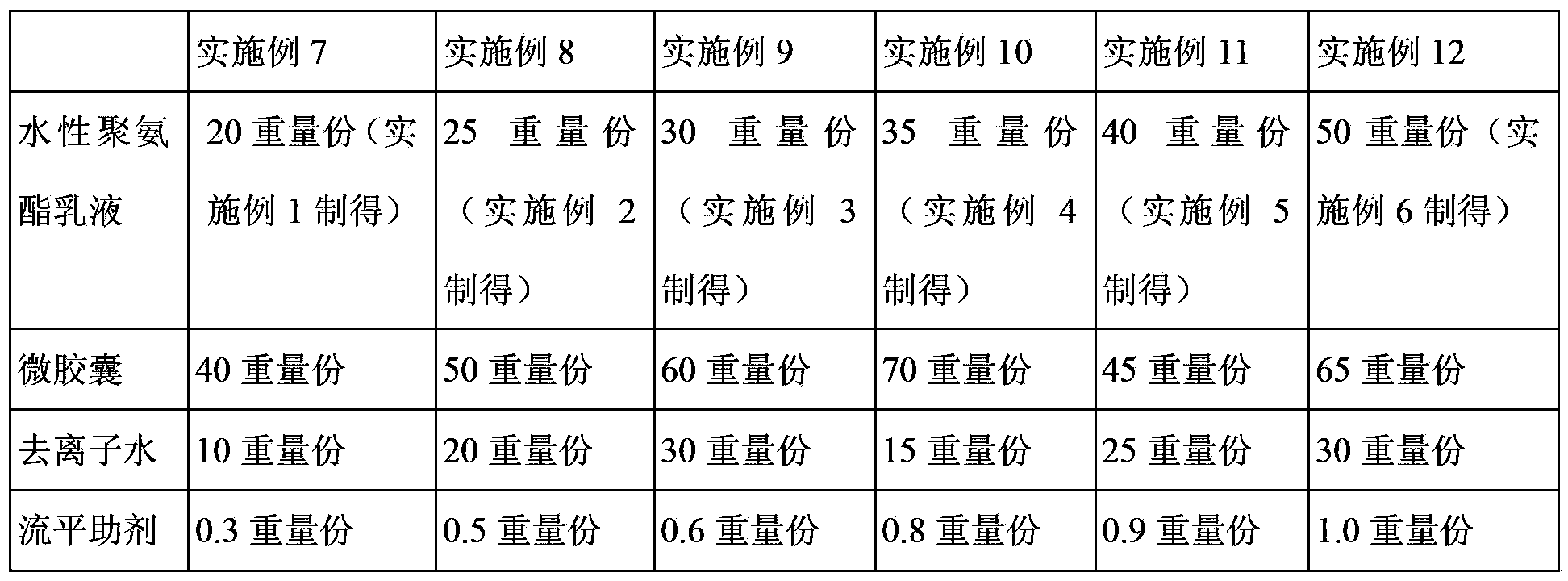

Examples

Embodiment 1

[0037] A kind of aqueous polyurethane emulsion is prepared according to the following preparation steps:

[0038] 1) Weigh the first part of raw materials, that is, weigh 18 parts by weight of polyester diol, 40 parts by weight of polyether diol (number average molecular weight Mn is 500), 13 parts by weight of polyethylene glycol, and 3 parts by weight of small molecules Diol chain extender and 26 diisocyanates are put into the reaction pot and stirred at 85°C for 4 hours to form reaction mixture I;

[0039] 2) When the reaction mixture I in step 1) becomes viscous, add the second part of raw materials, acetone, a low-boiling point solvent, in an amount of 1 to 1.2:2 compared with the total weight of the first part of raw materials, and lower the temperature to 50°C. Stir until the reaction mixture I is completely dissolved to form a reaction mixture II; the judging method for the thickening of the reaction mixture I is by preparing a 50% DMF (N,N-dimethylformamide) solution ...

Embodiment 2

[0043] A kind of aqueous polyurethane emulsion is prepared according to the following preparation steps:

[0044] 1) Weigh the first part of raw materials, that is, weigh 20 parts by weight of polyester diol, 48 parts by weight of polyether diol (the number average molecular weight Mn is 800), 15 parts by weight of polyethylene glycol, and 6 parts by weight of small molecules Polyamine chain extender and 23 diisocyanates are put into the reaction pot and stirred at 85°C for 5 hours to form reaction mixture I;

[0045] 2) When the reaction mixture I in step 1) becomes viscous, add the second part of the raw material butanone, a low-boiling point solvent, in an amount of 1.4:2 compared with the total weight of the first part of the raw material, lower the temperature to 58°C, and stir Until the reaction mixture I is completely dissolved to form the reaction mixture II; wherein the method for judging that the reaction mixture I becomes viscous is by preparing a 50% DMF solution o...

Embodiment 3

[0049] A kind of aqueous polyurethane emulsion is prepared according to the following preparation steps:

[0050] 1) Weigh the first part of raw materials, that is, weigh 9 parts by weight of polyester diol, 36 parts of polyether diol (the number average molecular weight Mn is 1000), 10 parts of polyethylene glycol, and 2 parts of small molecules Polyol chain extender and 20% aliphatic diisocyanate are put into the reaction pot and stirred at 70°C for 2 hours to form reaction mixture I;

[0051] 2) When the reaction mixture I in step 1) becomes viscous, add the second part of the raw material, acetone, a low-boiling point solvent, the amount of which is 1:2 compared with the total weight of the first part of the raw material, lower the temperature to 45°C, and stir until The reaction mixture I is completely dissolved to form a reaction mixture II; wherein the method for judging that the reaction mixture I becomes viscous is by preparing a 50% DMF solution of the reaction mixtu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com