Water-soluble floor paint resin and application thereof

A floor paint and water-soluble technology, applied in the field of paint and coatings, can solve problems such as fire hazards, air pollution, and damage to operators, and achieve the effects of meeting environmental protection performance, improving film hardness and wear resistance, and low VOC

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: Water-soluble floor paint resin, its production formula includes the following raw materials in parts by weight: 200 parts of castor oil; 90 parts of HDI; 100 parts of diethylene glycol; 55 parts of pentaerythritol; 35 parts of trimethylolpropane diallyl ether 70 parts of dimethylolpropionic acid; 2 parts of hypophosphorous acid; 9 parts of ammonia water; 180 parts of acetone.

[0017] The synthetic technique of present embodiment: throw castor oil, diethylene glycol, pentaerythritol, trimethylol propane diallyl ether, dimethylol propionic acid, hypophosphorous acid into four-necked flask, be warming up to 195~200 After esterification to an acid value of 55-65mgKOH / g at ℃, add ammonia water to neutralize, then add HDI to react at 80℃ for 3 hours, then dilute with acetone to obtain a water-soluble floor paint resin.

Embodiment 2

[0018] Example 2: Water-soluble floor paint resin, its production formula includes the following raw materials in parts by weight: 185 parts of castor oil; 80 parts of HDI; 90 parts of diethylene glycol; 60 parts of pentaerythritol; 40 parts of trimethylolpropane diallyl ether 65 parts of dimethylol propionic acid; 1.5 parts of hypophosphorous acid; 10 parts of ammonia water; 180 parts of acetone.

[0019] The synthesis process of this embodiment is the same as that of Example 1.

Embodiment 3

[0020] Example 3: Water-soluble floor paint resin, its production formula includes the following raw materials in parts by weight: 180 parts of castor oil; 85 parts of HDI; 80 parts of diethylene glycol; 50 parts of pentaerythritol; 30 parts of trimethylolpropane diallyl ether 60 parts of dimethylolpropionic acid; 1 part of hypophosphorous acid; 8 parts of ammonia water; 183 parts of acetone.

[0021] The synthesis process of this embodiment is the same as that of Example 1.

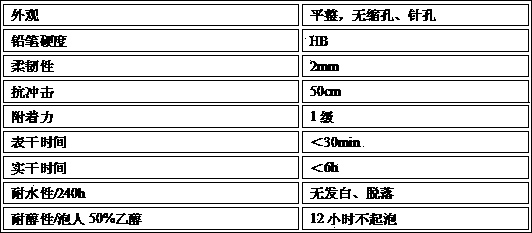

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com