Poly(carbonate-ether) polyurethane acrylate, ultraviolet-curable antistatic coating and preparation method of ultraviolet-curable antistatic coating

A polyurethane acrylate and isobornyl acrylate technology, which is applied in polyurea/polyurethane coatings, conductive coatings, coatings, etc., can solve the problems of low efficiency of antistatic coatings, meet the requirements of fast assembly line coating, and improve antistatic durability performance, improve the effect of antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

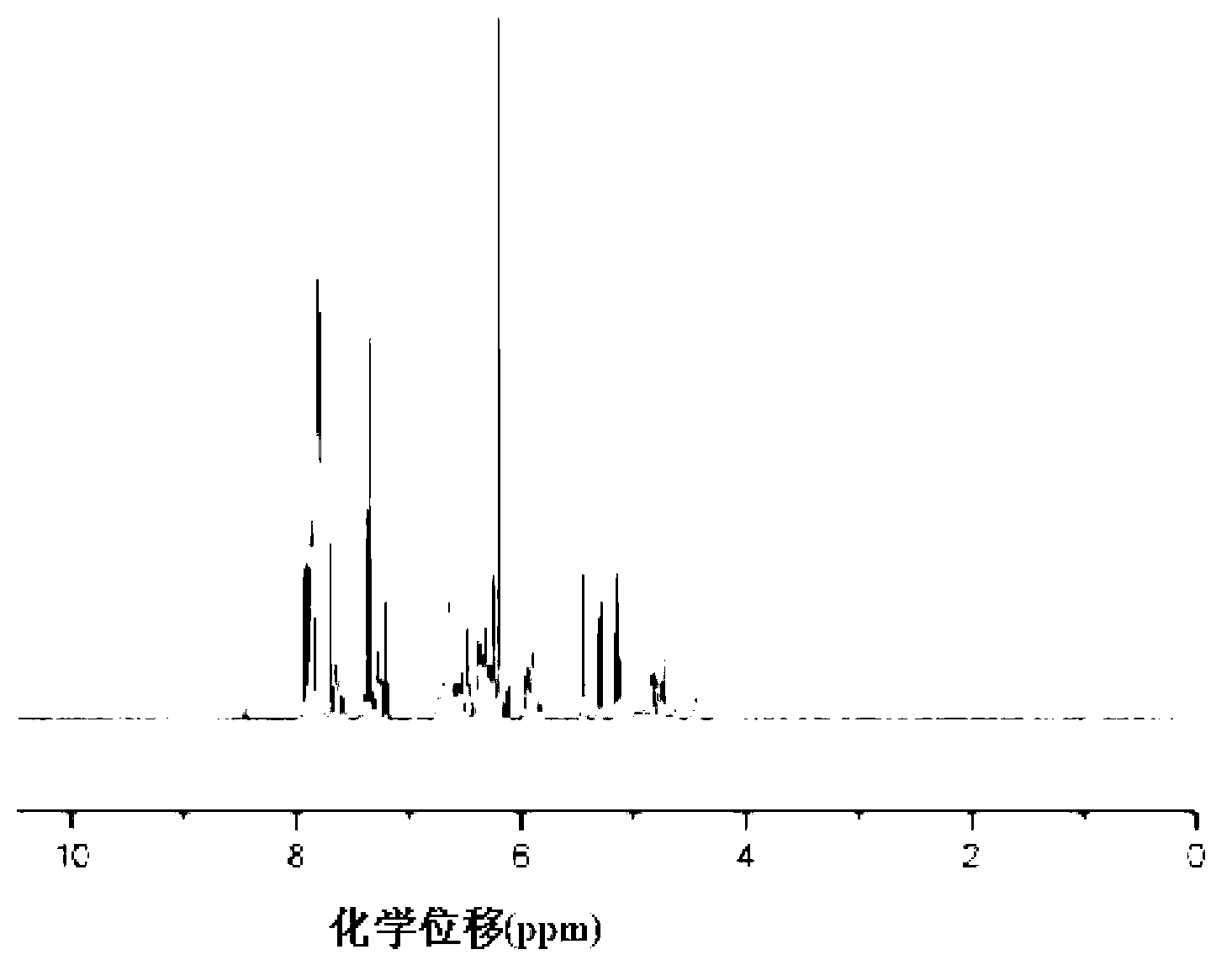

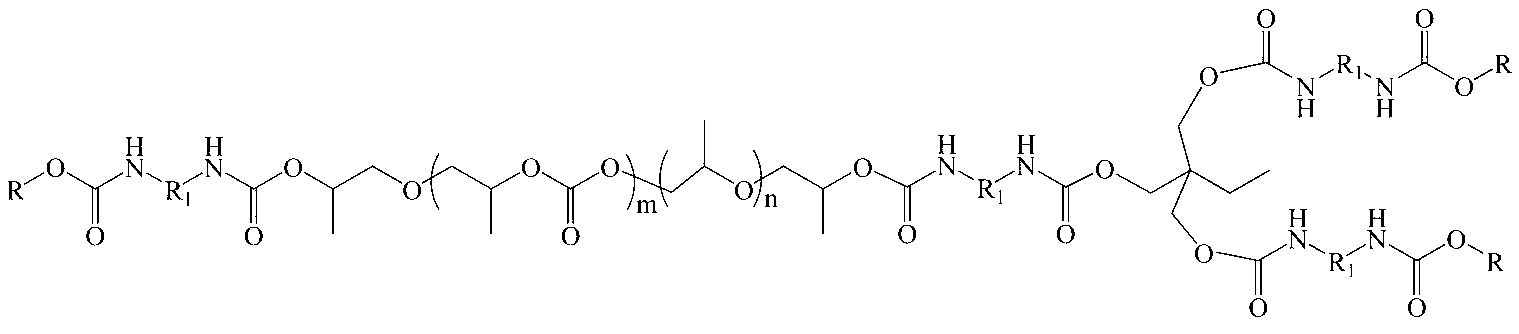

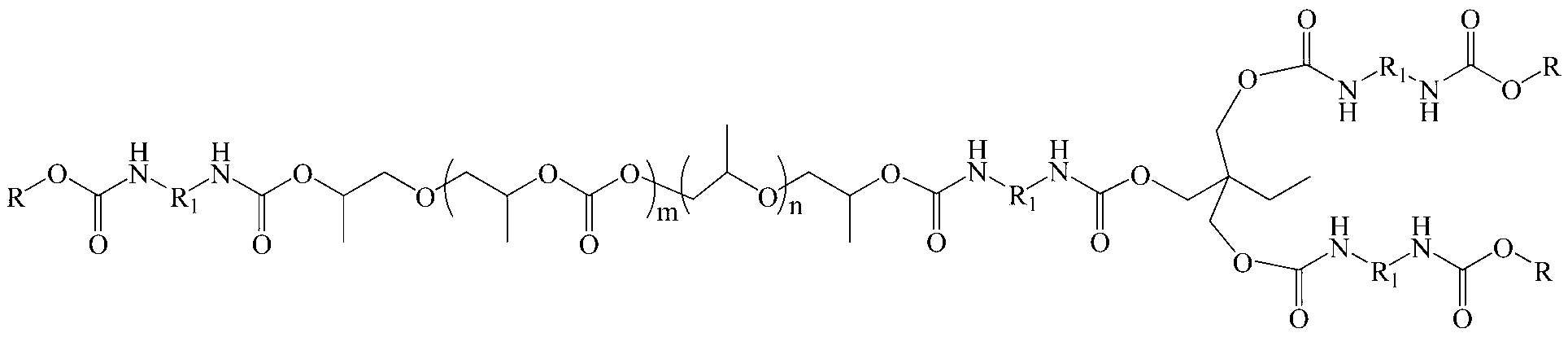

[0065] The preparation method of poly(carbonate-ether) type polyurethane acrylate comprises the following steps:

[0066] (1) under the protection of a dry inert atmosphere, add poly(carbonate-ether) glycol and trimethylolpropane to the reaction unit, and distill under reduced pressure;

[0067] (2) add isobornyl acrylate and diisocyanate, and react to obtain the first intermediate;

[0068] (3) Adding a catalyst and a hydroxyl-containing acrylate dissolved in p-hydroxyanisole to the first intermediate, and continuing the reaction to obtain poly(carbonate-ether) polyurethane acrylate.

[0069] The poly(carbonate-ether) glycol of the present invention can be prepared by known techniques in the art, see patent 201210086834.X for details; the preferred number average molecular weight is a poly(carbonate-ether) glycol with a number average molecular weight of 1500-7500 Daltons , more preferably poly(carbonate-ether) glycols with a number average molecular weight of 1500-2800 Dalt...

Embodiment 1

[0102] Preparation of conductive polyaniline dispersion:

[0103] Add 1g of intrinsic polyaniline to 35g of 1,6-hexanediol diacrylate and 20g of isobornyl acrylate, raise the temperature to 110°C, stir at 2000rpm for 0.5h, then add 3.5g of dodecane Base benzene sulfonic acid, continue to stir at 2000rpm speed 8h, stop stirring, obtain conductive polyaniline dispersion liquid.

Embodiment 2

[0105] Preparation of conductive polyaniline dispersion:

[0106] Add 3g of intrinsic polyaniline to 40g of 1,6-hexanediol diacrylate and 28g of isobornyl acrylate, raise the temperature to 115°C, stir at 2200rpm for 1h, then add 4.8g of dodecyl benzenesulfonic acid, continue to stir at 2200rpm for 9h, stop stirring to obtain conductive polyaniline dispersion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com