Compound modified aliphatic amine curing agent

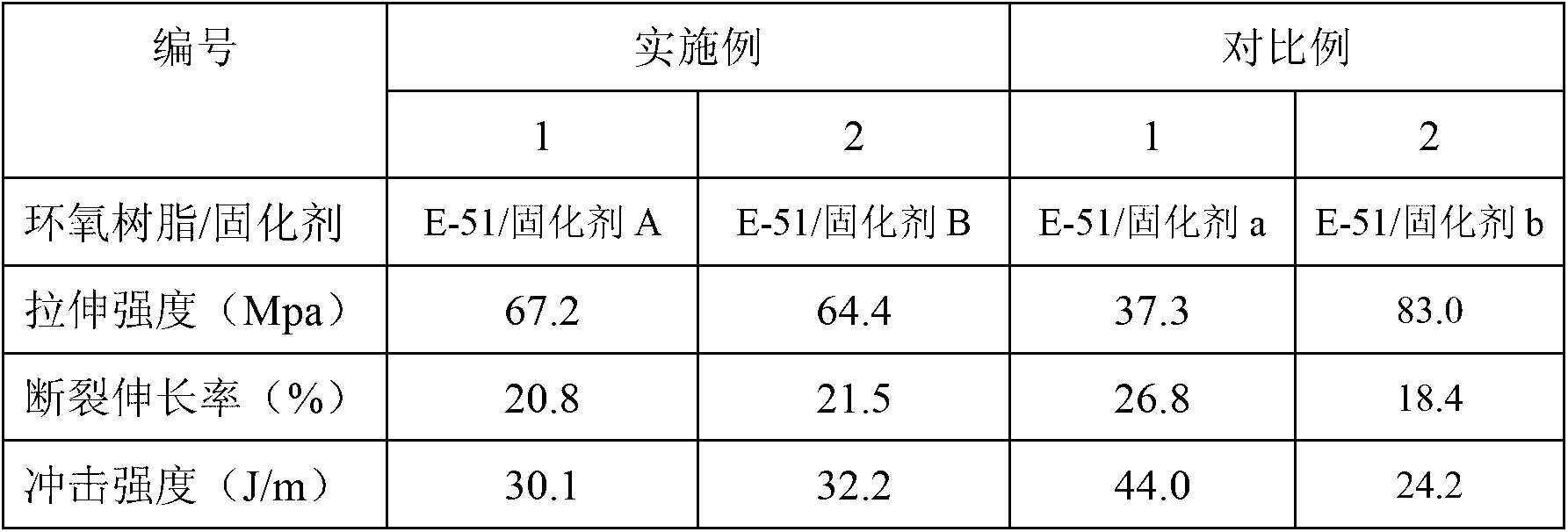

A technology of aliphatic amines and curing agents, applied in the direction of organic chemistry, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of reduced strength, shortened operation period, etc., and achieve the effects of reducing consumption, reducing energy consumption, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

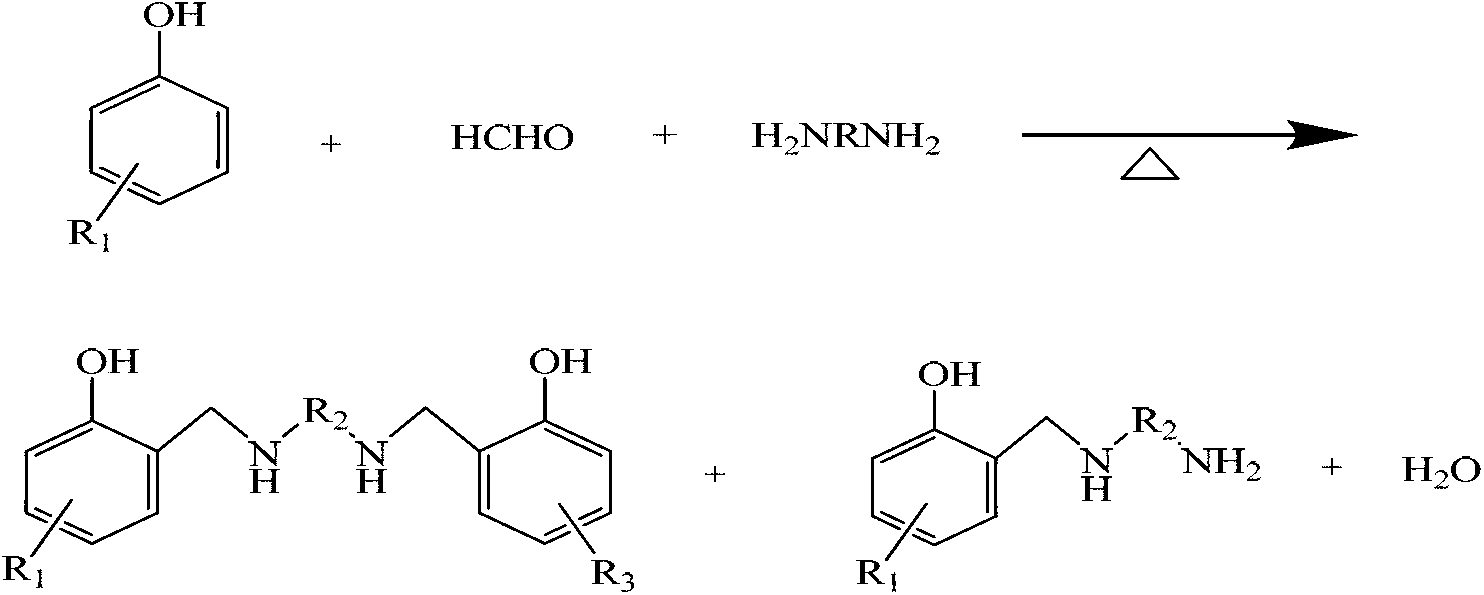

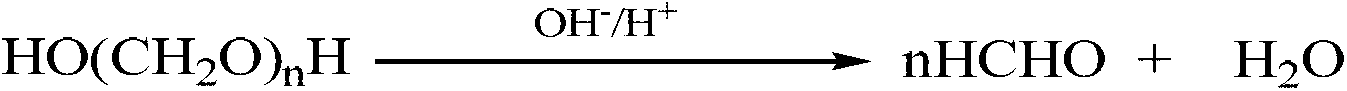

Method used

Image

Examples

Embodiment 1

[0030] Add 60g cardanol, 21.6g m-cresol, 23.2g hexamethylenediamine, and 20.6g triethylenediamine into a 250ml four-neck flask equipped with a stirring, reflux device, and a thermometer, and stir for 20-30min to make it evenly mixed. And raise the temperature to 85°C; add 12.6g of paraformaldehyde to the reaction solution in 5~6 times at 85°C within 0.5~1h; after the paraformaldehyde is completely dissolved, let the reaction solution react at 85°C for 3h; then reduce Distill under reduced pressure at a temperature of 85-95°C and a pressure of 0.0013-0.0213Mpa, and stop the vacuum distillation until there are no more droplets on the inner wall of the flask; collect the product after the product cools down. The obtained product was a reddish-brown liquid with an amine value of 390 mgKOH / g and a viscosity of 940 mPa·s (25°C).

Embodiment 2

[0032] In a 250ml four-necked flask equipped with a stirring, reflux device, and a thermometer, add 60g of cardanol, 44g of nonylphenol, 23.2g of hexamethylenediamine, and 20.6g of triethylenediamine, and stir for 20 to 30 minutes to make it evenly mixed, and Raise the temperature to 85°C; add 12.6g of paraformaldehyde to the reaction solution in 5~6 times at 85°C within 0.5~1h; after the paraformaldehyde is completely dissolved, let the reaction solution react at 85°C for 3h; then depressurize Distillation at a temperature of 85-95°C and a pressure of 0.0013-0.0213Mpa. Stop vacuum distillation until there are no more droplets on the inner wall of the flask; collect the product after the product cools down. The obtained product is a reddish-brown liquid with an amine value of 325 mgKOH / g and a viscosity of 1300 mPa·s (25°C).

Embodiment 3

[0034]Add 30g cardanol, 10.8g m-cresol, 13.9g hexamethylenediamine, and 8.2g triethylenediamine into a 250ml four-neck flask equipped with a stirring, reflux device, and a thermometer, and stir for 20 to 30 minutes to make it evenly mixed. And raise the temperature to 85°C; add 6.3g paraformaldehyde to the reaction solution in 5~6 times at 85°C within 0.5~1h; after the paraformaldehyde is completely dissolved, let the reaction solution react at 85°C for 3h; then reduce Distill under reduced pressure at a temperature of 85-95°C and a pressure of 0.0013-0.0213Mpa, and stop the vacuum distillation until there are no more droplets on the inner wall of the flask; collect the product after the product cools down. The obtained product is a reddish-brown liquid with an amine value of 380 mgKOH / g and a viscosity of 980 mPa·s (25°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amine value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com