Yttrium oxide phosphors for up-conversion luminescence, and preparation method and application thereof

A technology of phosphor powder and yttrium oxide is applied in the field of phosphor powder to achieve the effects of low energy consumption, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

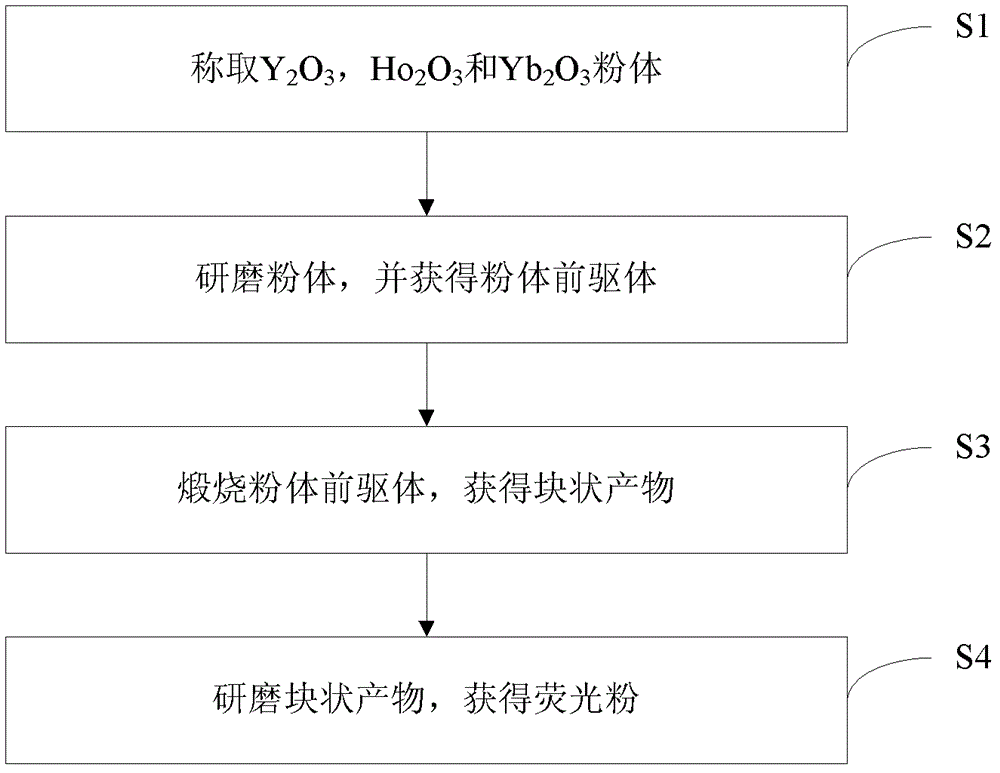

[0024] The preparation method of the above-mentioned yttrium oxide up-conversion luminescent phosphor, such as figure 1 shown, including the following steps:

[0025] Step S1, according to the structural formula Y 2-x-y o 3 :xHo 3+ ,yYb 3+ The stoichiometric ratio of each element in the formula, weighing the powder: Y 2 o 3 、Ho 2 o 3 and Yb 2 o 3 ;

[0026] Step S2, mixing and grinding the powder weighed in step S1 for 20-60 minutes to obtain a powder precursor;

[0027] Step S3, calcining the powder precursor in step S2 at 800-1000°C for 0.5-5 hours, then cooling down to 100-500°C, keeping it at this temperature for 0.5-3 hours and then cooling to room temperature to obtain a block product ;

[0028] Step S4, grinding the bulk product in step S3 to obtain the yttrium oxide up-converted phosphor powder; the phosphor powder has a structural formula of Y 2-x-y o 3 :xHo 3+ ,yYb 3+ ; Among them, Ho 3+ and Yb 3+ for dopant ions;

[0029] Among them, the structura...

Embodiment 1

[0038] 1. Choose powder with a purity of 99.99%: Y 2 o 3 , Ho 2 o 3 and Yb 2 o 3 Powder, its mass is 2.24g, 0.113g and 0.197g respectively;

[0039] 2. Put the above powder in a corundum mortar and grind it for 40 minutes to mix it evenly to obtain a powder precursor;

[0040] 3. Put the powder precursor in a muffle furnace, burn it at 950°C for 3 hours, then cool it to 250°C and keep it for 3 hours, then cool it naturally to room temperature and take out the block product.

[0041] 4. Grinding and pulverizing the bulk product to obtain the structural formula Y 1.84 o 3 :0.06Ho 3+ , 0.1Yb 3+ Up-converting phosphors.

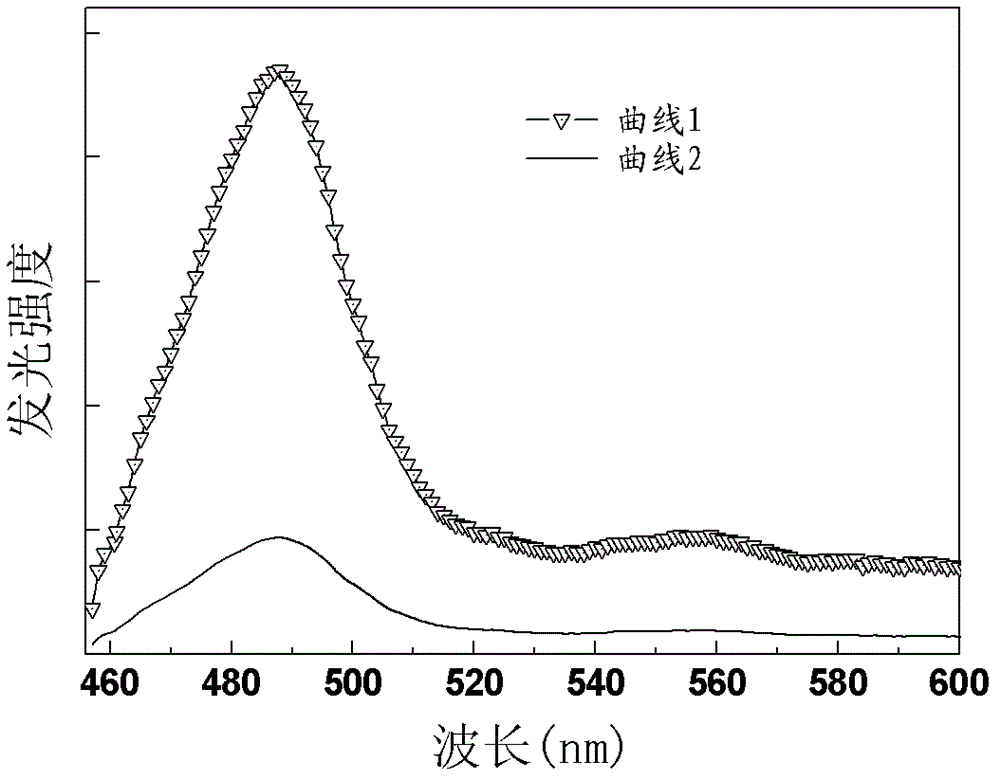

[0042] figure 2 The electroluminescence spectrogram of the yttrium oxide up-converting luminescent phosphor powder prepared in Example 1 and the phosphor powder not doped with Yb element in the comparative example; figure 2 It can be seen that curve 1 is the photoluminescence spectrum of the sample in Example 1, and the excitation wavelength is 640nm;...

Embodiment 2

[0044] 1. Choose powder with a purity of 99.99%: Y 2 o 3 , Ho 2 o 3 and Yb 2 o 3 Powder, the mass ratios are 2.39g, 0.038g and 0.039g respectively;

[0045] 2. Put the above powder in a corundum mortar and grind it for 20 minutes to mix it evenly to obtain a powder precursor;

[0046] 3. Put the powder precursor in a muffle furnace, burn it at 800°C for 5 hours, then cool it to 100°C and keep it for 3 hours, then cool it naturally to room temperature and take out the block product;

[0047] 4. Grinding and pulverizing the bulk product to obtain the structural formula Y 1.96 o 3 :0.02Ho 3+ , 0.02Yb 3+ Up-converting phosphors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com