Low-carbon high-hydrogen coal dust modifier and coal blending coking method using same

A coal blending coking and modifier technology, applied in coking ovens, petroleum industry, etc., can solve the problem of low long-flame coal consumption, achieve the effect of reducing coking costs and saving coking coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

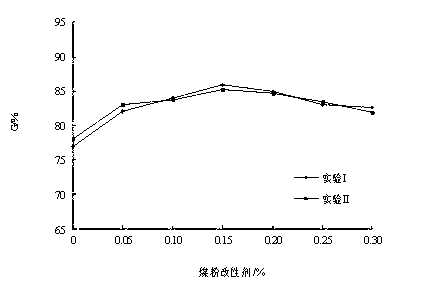

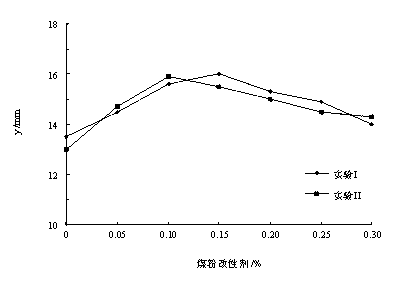

Examples

Embodiment 1

[0025] Preparation of low -carbon high hydrogen coal flouter modifiers: selected 0.6kg of boric acid in acid substances, 0.02 kg of adenic acid; 0.23kg of calcium propionate in the surfactant substance, 0.15kg of potassium dumb acid, a total of 1.0kg, a total of 1.0kgIngredients, grinding and mixing uniformly;

[0026] Low -carbon -high hydrogen coal molicism: Take the above -mentioned modifiers 0.5 kg (0.5 ‰ of the weight of coking with coal weight), 100 kg of Changyan coal (accounted for 10%of the weight of coal with coal), put in the automatic heating device with the belt automatic heating deviceThe modifier is fully mixed, reacted, and modified. The temperature in the modifier is controlled at 25 ° C, and the reaction time is 15 minutes;

[0027] Coal -assigned coking: Take 100 kg of the above modifier coal (accounted for 10%of the weight of coke and coal), and then crushed, mixed with 500kg coking coal, 1 / 3 of 1 / 3 coke coal of 400kg, mixed in the coke furnace according to con...

Embodiment 2

[0030] Preparation of low -carbon high hydrogen coal flouter modifiers: Choose 1.2kg of boric acid in acid substances, 0.1 kg of dulate dilate, lanine accounts for 0.1 kg;Sodium alkyl sodium 0.2 kg, potassium potassium 0.2 kg, a total of 2.0kg raw materials, loaded into the ball mill and mixed with the ball and mixed;

[0031] Low -carbon -high hydrogen coal molicism: Take the above -mentioned modifiers 1.5 kg (accounting for 1.5 ‰ of the weight of the coal with coal), 150 kg of not sticky coal (15%of the weight of the coal combined with coal), put the automatic heating device in the bandThe modifiers are fully mixed, react, and modified.

[0032] Coal -assigned coking: Take the above -mentioned modified coal 150 kg (15%of the weight of coke and coal), and then crushed, mixed, mixed, installed in convergence furnaces with conventional production process with scorched coal 300kg, 300kg of fertilizer coal, 1 / 3 coking coal 250kg.It

[0033] Cold indicators of coke: M40: 81.3%, M10: 6...

Embodiment 3

[0035] Preparation of low -carbon high hydrogen coal flouter modifiers: selected 2.8kg of boric acid in acid substances, 0.08 kg of nichab acid, 0.12 kg of dulate dilate, 0.2kg of alanine;Calcium 0.2kg, sodium alkyl sulfonate 0.12 kg, potassium potassium 0.16kg, and calcium of calcium dilite 0.32 kg, a total of 4.0kg raw materials, mixed in a mixed mixer;

[0036] Low -carbon -high hydrogen coal molicism: Take the above -mentioned modified agent 3.5 kg (accounting for 3.5 ‰ of the weight of the coal with coal), and 250 kg of low -carbon high -hydrogen weak sticky coal (accounting for 25%of the weight of coal with coal), putThe modifier of the automatic heating device is fully mixed, reacts, and modified in the modifier. The temperature in the modifier is controlled at 100 ° C, and the reaction time is 35 minutes;

[0037] Coal with coal with coal: Take the above -mentioned modified coal 250 kg (25%of the weight of coke and coal), and then crushed, mixed, installed with 300kg cokin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com