Multi-path high-energy ultrasonic field treatment device for regulating and controlling welding residual stress

A high-energy ultrasonic and high-energy technology, used in heat treatment furnaces, heat treatment equipment, and process efficiency improvements, can solve the problems of easy oxidation of workpieces, elimination of residual stress, inconvenient on-site use and operation, and improve corrosion resistance and wear resistance. Effects of capacity, stress value improvement, increase and overall structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

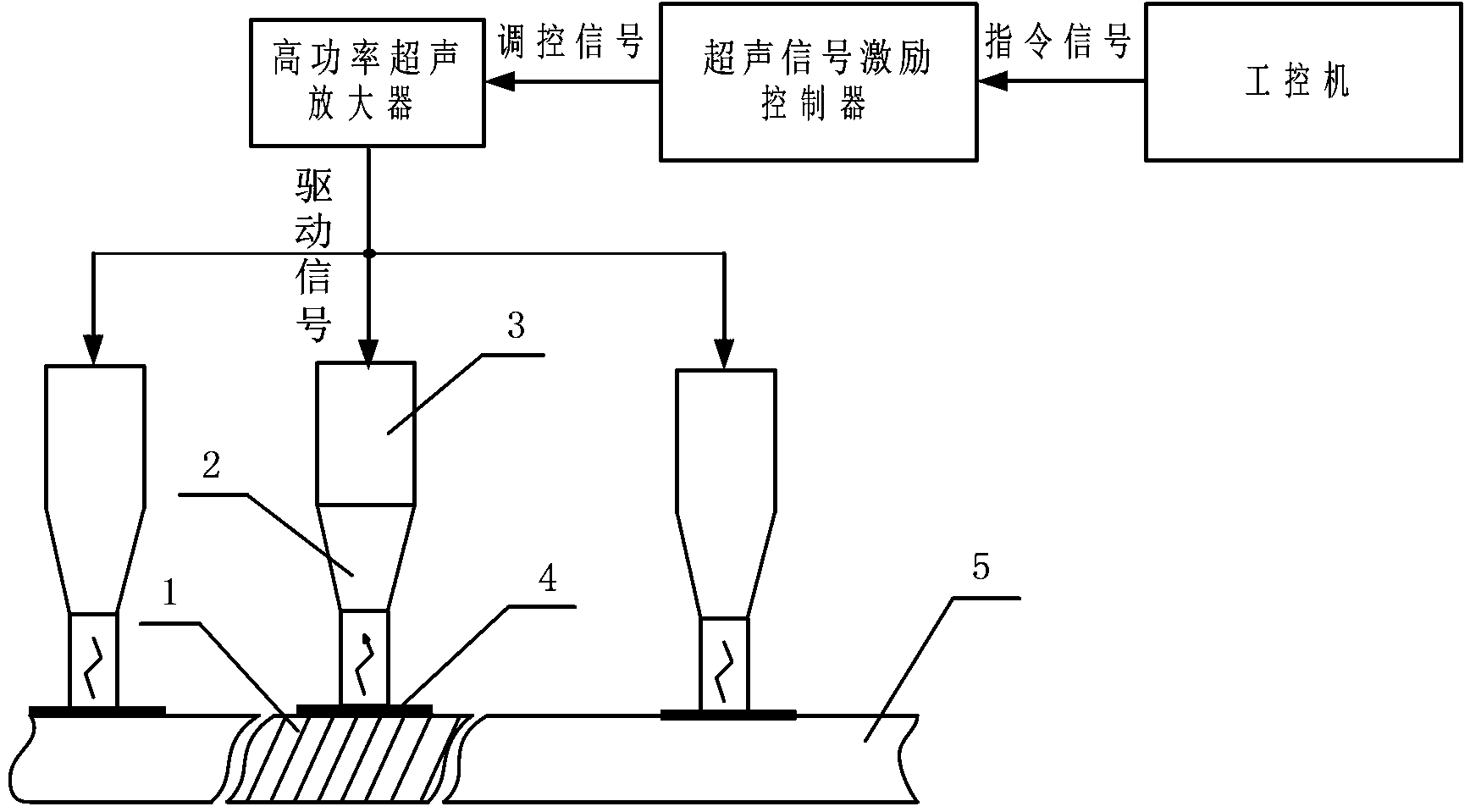

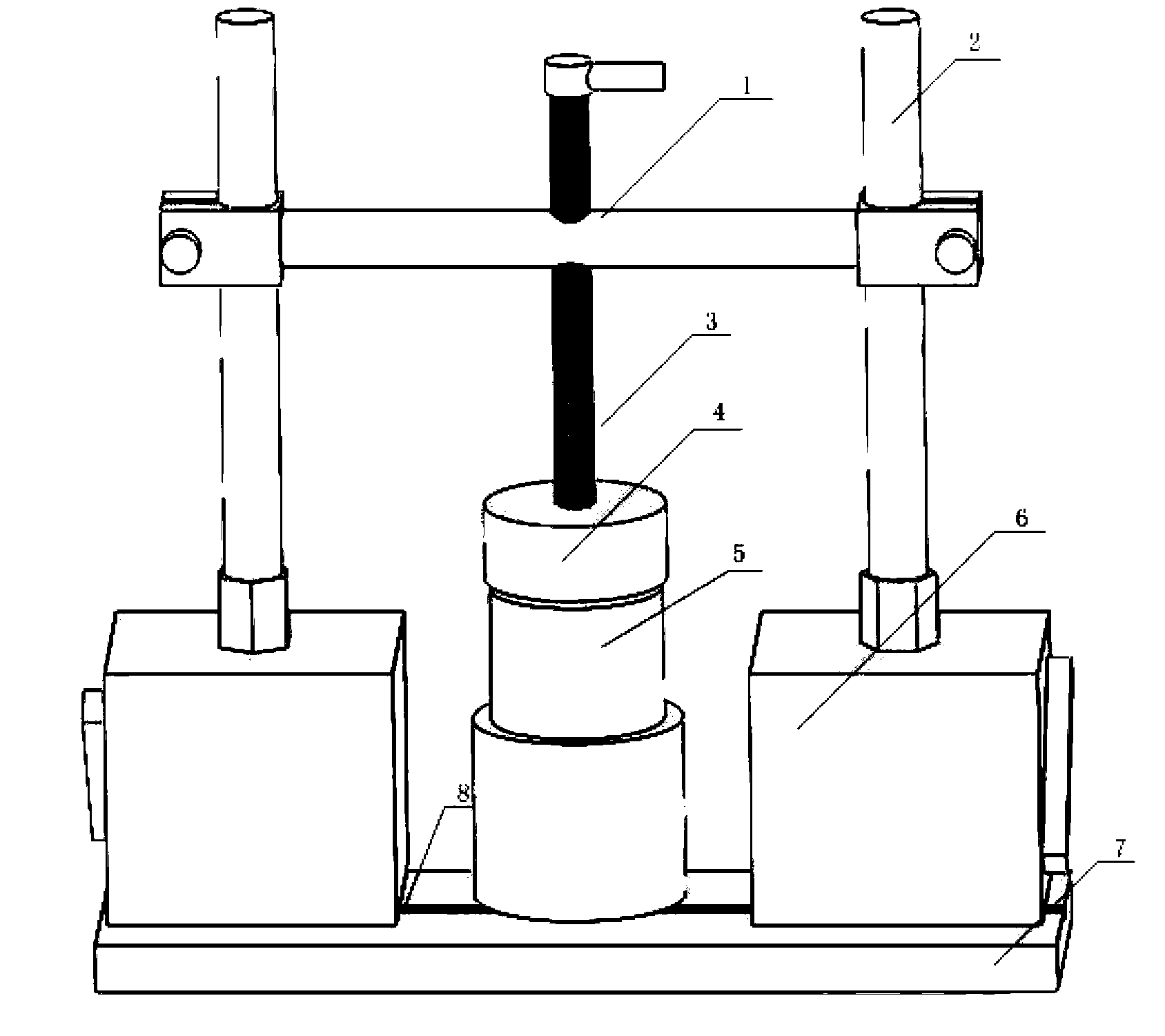

[0018] Such as figure 1 Shown is the principle diagram of the welding residual stress multi-channel high-energy ultrasonic sound field processing device of the present invention, which includes: industrial computer, ultrasonic signal excitation controller, high-power ultrasonic amplifier, high-energy transducer and auxiliary devices. figure 2 Schematic of the clamping setup when working for a single high-energy transducer. When adjusting the residual stress concentration area of the welded specimen, two strong magnetic suction seats are adsorbed on the part of the welded body to be regulated, and the fixed middle rod and threaded rod are adjusted to adjust the high-energy ultrasonic transducer to the stress concentration area of the weld. The pressure plate keeps the test piece in fixed contact with the transducer, and then connects the two ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com