High corrosion resistance rare earth-iron chromium silicon carbon magnetocaloric material and preparation method thereof

A magnetocaloric material, high corrosion resistance technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve problems such as difficulty in coating and damage, and achieve the effects of uniform C content, cost saving, and strong corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

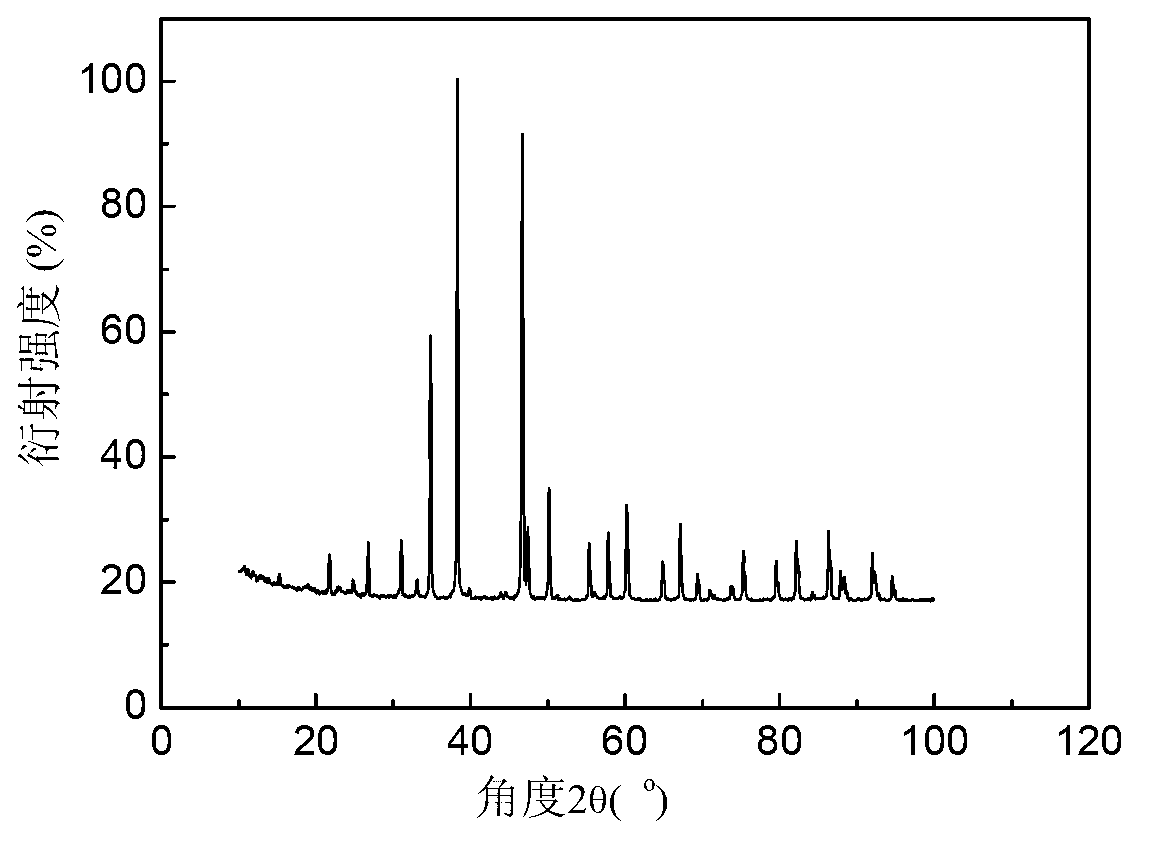

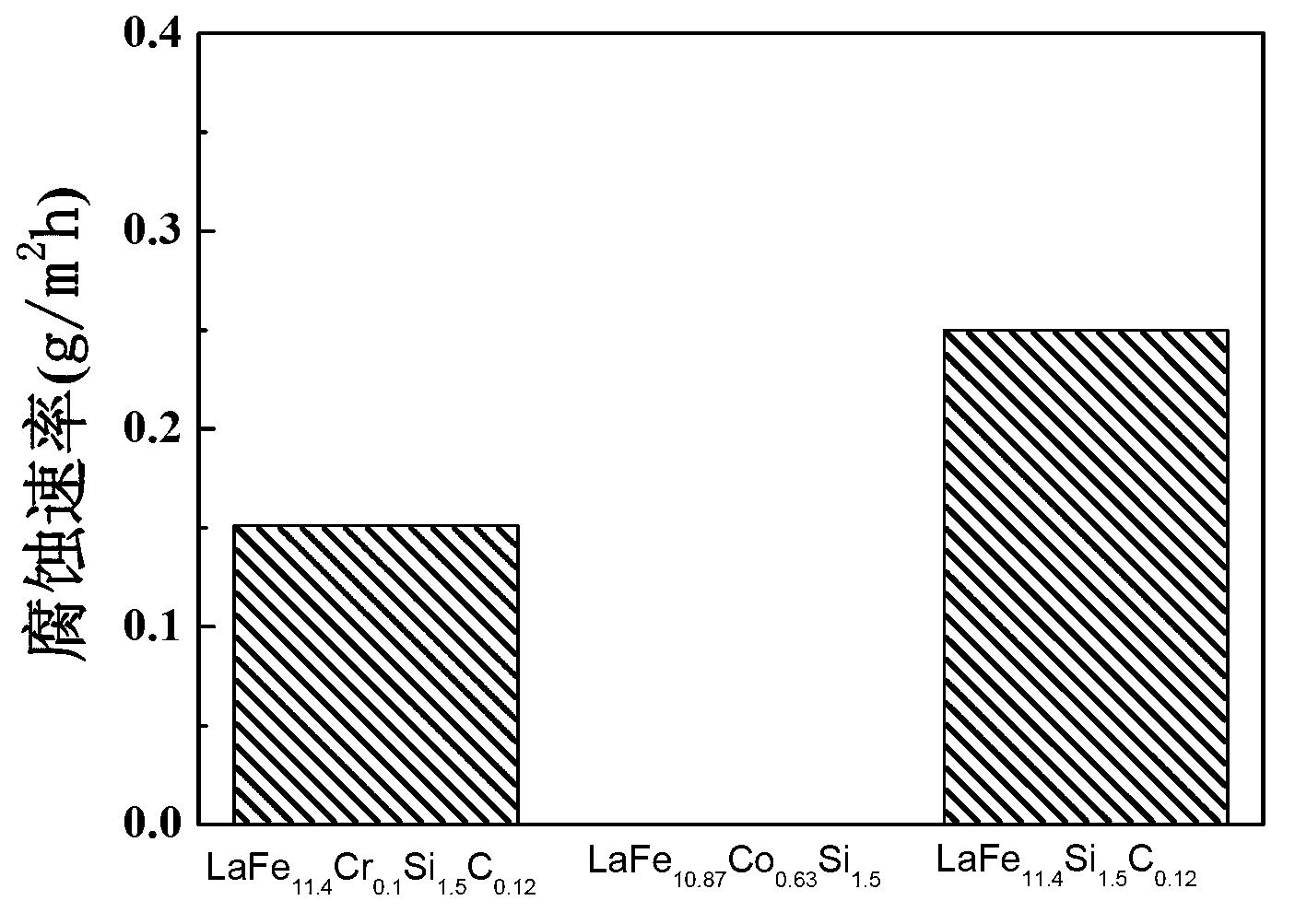

[0036] La, Fe, Si, Cr, C and other raw materials are formulated into LaFe according to their chemical composition 11.3 Cr 0.2 Si 1.5 C 0.12 and LaFeSi, then according to the volume ratio of 0.97 (LaFe 11.3 Cr 0.2 Si 1.5 C 0.12 ): 0.3 (LaFeSi) to prepare three kilograms of 1# corrosion-resistant magnetocaloric material, and at the same time, according to the chemical composition, make it into the comparison sample LaFe 10.87 co 0.63 Si 1.5 、LaFe 11.4 Si 1.5 C 0.12 Three kilograms are put into a vacuum induction furnace for smelting, and after smelting, pour it into a cylindrical mold with a diameter of 50mm, a wall thickness of 3mm, and a bottom thickness of 30mm to obtain an ingot with uniform composition. The ingot was annealed at 1080°C for 3 days, and then directly put into ice water for quick quenching. figure 1 It shows the X-ray diffraction pattern of the 1# corrosion-resistant magnetocaloric material of the present invention, wherein the abscissa is the dif...

Embodiment 2

[0038] Pure La mixed with industrial pure mixed rare earths Re (La / Re: 28.27 wt.%, Ce / Re: 50.46 wt.%, Pr / Re: 5.55 wt.%, Nd / Re: 15.66 wt.%)), Fe, Si, Cr, C raw materials respectively according to chemical composition La 0.8 (Ce, Pr, Nd) 0.2 Fe 11.25 mn 0.1 Cr 0.3 Si 1.5 C 0.2 and LaFeSi preparation, and then according to the volume ratio of 0.98 (LaFe 11.3 Cr 0.2 Si 1.5 C 0.12 ): 0.2 (LaFeSi) ratio to form 2# corrosion-resistant magneto-caloric material, melted in a vacuum induction furnace to obtain an ingot, and then annealed the ingot at 1100 ° C for 2 days, directly put it into ice water for quick quenching, and obtained A compound of uniform composition. Figure 6 Represents the X-ray diffraction pattern of 2# corrosion-resistant magnetocaloric material, where the abscissa is the diffraction angle, and the ordinate is the diffraction intensity. From Figure 6 It can be seen that, with the assistance of LaFeSi, the 2# corrosion-resistant magnetocaloric material ...

Embodiment 3

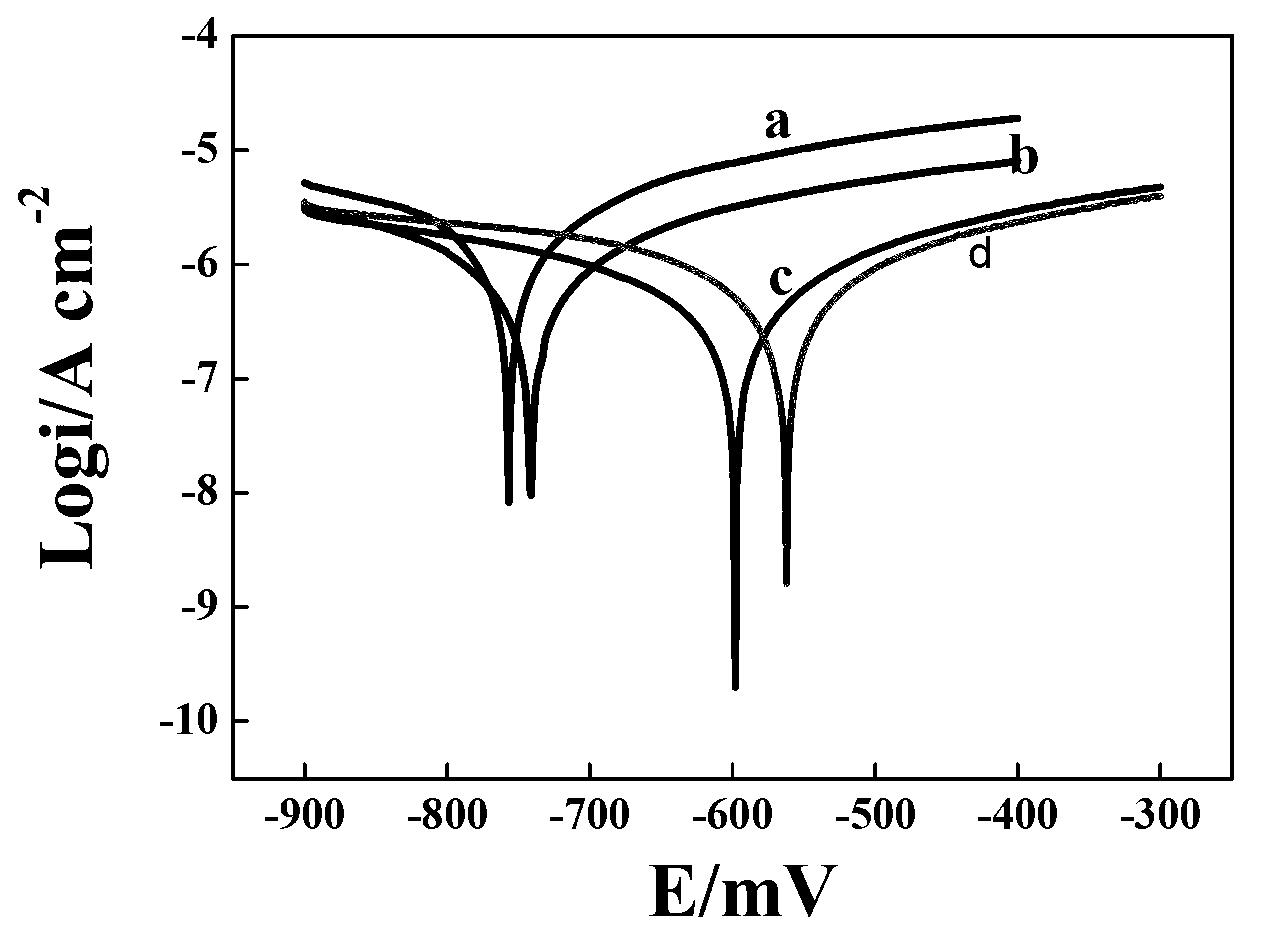

[0040] La, Fe, Si, Cr, Mn, C and other raw materials are formulated into LaFe according to their chemical composition 11.1 mn 0.1 Cr 0.3 Si 1.5 C 0.15 and LaFeSi, then according to the volume ratio of 0.99 (LaFe 11.1 mn 0.1 Cr 0.3 Si 1.5 C 0.15 ): The ratio of 0.1 (LaFeSi) is formulated into 3# corrosion-resistant magneto-caloric material, which is put into an atomizing ball-forming device for melting and then quenched into balls to obtain small balls of 0.5-1mm. The pellets were annealed at 1080°C for 1 day, and then directly quenched in ice water. image 3 The polarization curves of the 3# corrosion-resistant magnetocaloric pellets of the present invention and the materials in Example 1 are shown. From image 3 It can be seen that the corrosion current density of the 3# corrosion-resistant magnetocaloric material of the present invention is lower than that of the comparison material LaFe 10.87 co 0.63 Si 1.5 、LaFe 11.4 Si 1.5 C 0.12 , while the corrosion pote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com