Novel high-speed brake lining

A high-speed, new type of technology, applied in friction linings, other chemical processes, chemical instruments and methods, etc., can solve the problems of steel back deformation, high safety hazards, and virtual welding, etc., to eliminate welding deformation, enhance strength, and avoid easy welding. The effect of falling edge and corner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

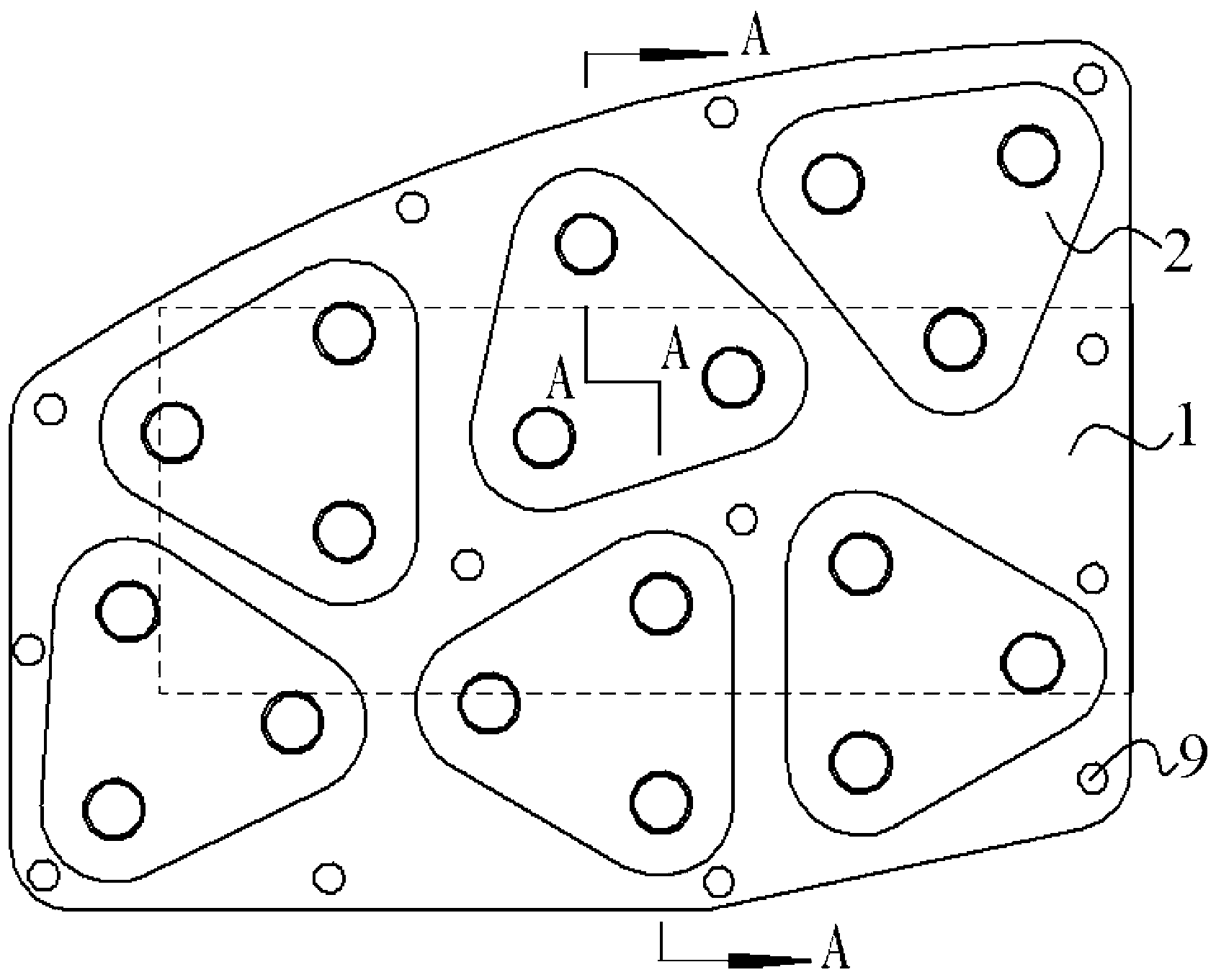

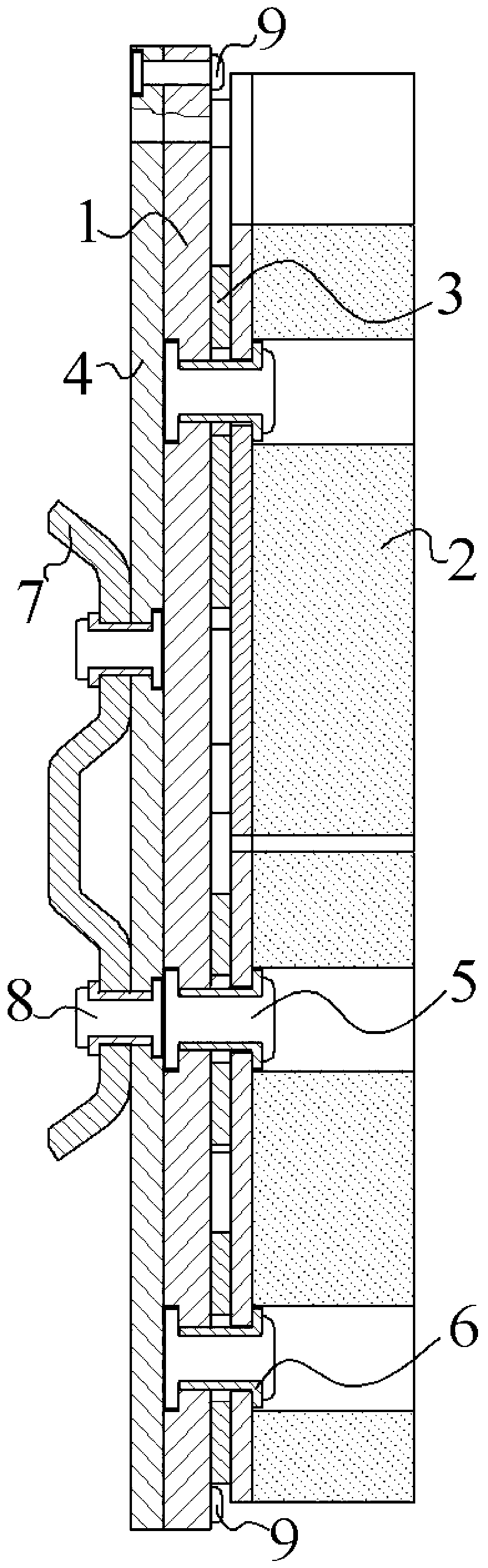

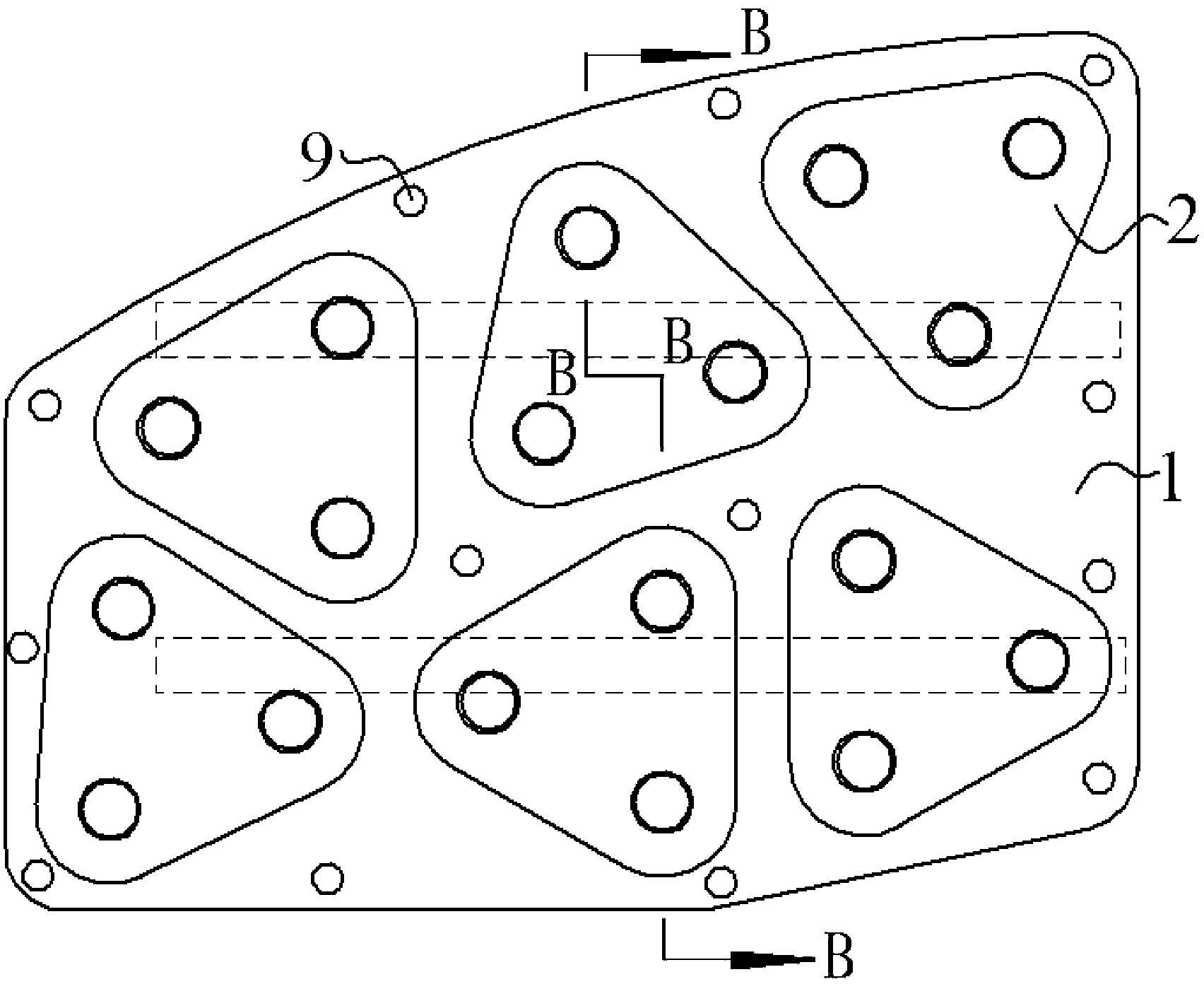

[0016] Below in conjunction with accompanying drawing, the present invention will be further described, as Figure 1~Figure 4 As shown, the new high-speed brake pad mainly includes a steel back 1, a brake block 2 and a dovetail plate 7, the front of the steel back 1 is riveted with a brake block 2, the back of the steel back 1 is riveted with a connecting plate 4, and the connecting plate 4 is provided with a dovetail Plate 7; the weight percentage of the material formula used in the brake block 2 is: copper powder 58, iron powder 4, tin powder 4, chromium powder 2, titanium powder 2, nickel powder 4, bismuth powder 2, graphite 9, nitride Boron 1, aluminum oxide 3, silicon dioxide 6, and zircon 5, the above-mentioned material formula is cold-pressed and sintered on the skeleton to obtain the brake block 2 according to the prior art. figure 1 The dotted line in is the outline of the outer edge of the dovetail plate 7, and the number of brake blocks 2 depends on the area of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com