Aluminum paste for silicon solar cell

A technology of silicon solar cells and aluminum paste, applied in circuits, electrical components, conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as poor sintering performance of aluminum powder, low battery efficiency, and difficult conductive connections. Achieve the effects of reducing curvature, improving conversion efficiency, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

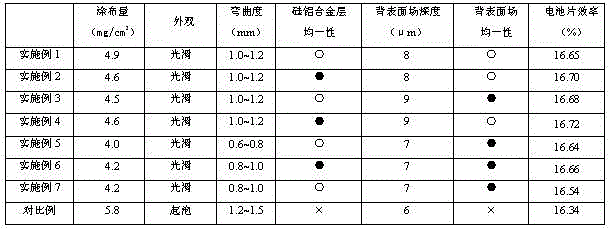

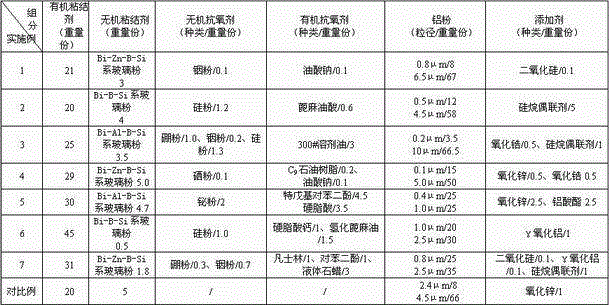

Examples

Embodiment Construction

[0023] The sintering process of solar cells is divided into two stages: pre-sintering and high-temperature sintering. The temperature in the pre-sintering stage is about 300-550°C. At this stage, the organic matter in the aluminum paste undergoes thermal oxidation decomposition, and the organic binder in the aluminum paste is generally Use ethyl cellulose resin or acrylic resin, the decomposition temperature is low, it has been completely decomposed and volatilized at the beginning of sintering, and has lost its protective effect on aluminum powder; the high temperature sintering stage is about 550-850°C, and the melting point of aluminum is 660°C , in the high-temperature sintering stage, the aluminum powder melts and reacts with the silicon matrix to form a silicon-aluminum alloy, and in the subsequent cooling process, the silicon-aluminum alloy segregates to form a silicon layer doped with aluminum atoms—the back surface field (BSF layer ). In the pre-sintering and high-tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com