Defluorination adsorbent as well as preparation method and application thereof

A technology of adsorbent and raw material, applied in the field of environmentally friendly adsorbent for treating fluoride ions in industrial wastewater and its preparation field, can solve the problems of small pH application range, small saturated adsorption capacity, small adsorption capacity, etc., and achieve simple preparation method, fluorine ion Large adsorption capacity and high fluorine removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

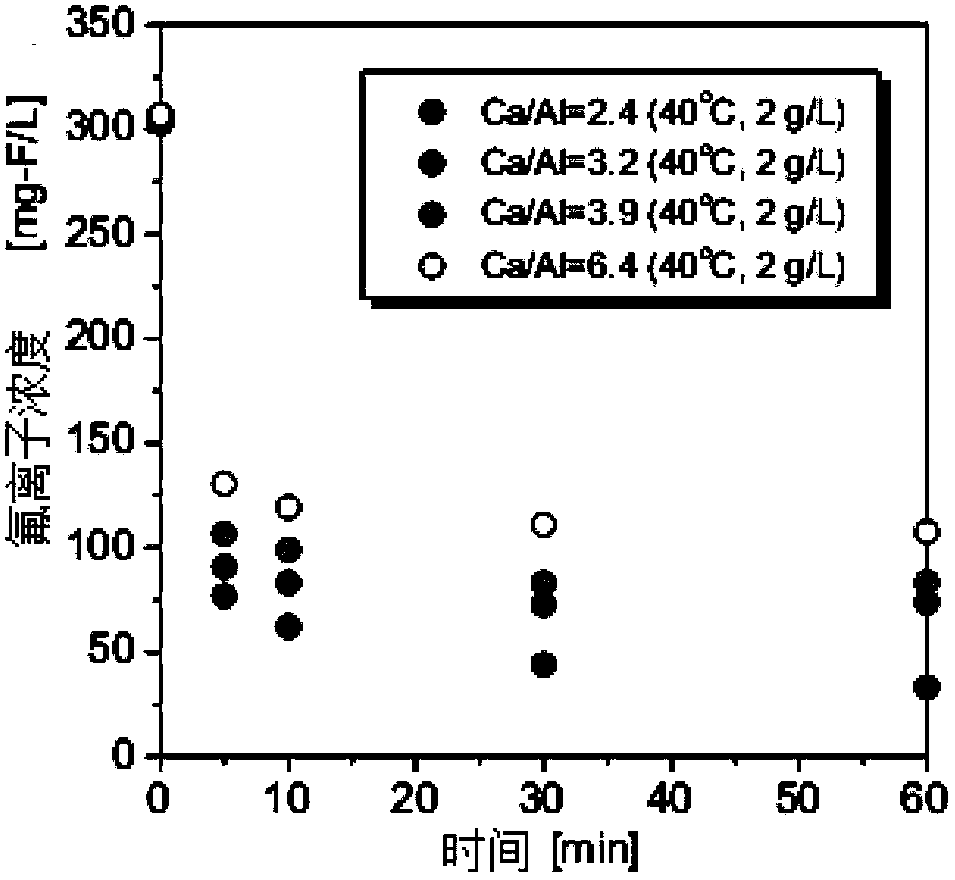

[0029] In parts by mass, mix 1 part of ordinary Portland cement with 3 parts of water and stir for 1 hour to prepare cement slurry; then add a pre-calculated amount of aluminum sulfate solid (85% by mass) into the cement slurry, so that The calcium-aluminum molar ratios are 2.4, 3.2, 3.9, 6.4 respectively (the aluminum content in the cement raw materials is considered in the calculation); the colloidal solid obtained after stirring the cement slurry in a water bath at a constant temperature of 25°C for 24 hours uses nitrocellulose with a pore size of 8.0 μm The filter membrane was subjected to suction filtration; the filter cake was dried in an oven set at 40°C for 24 hours to constant weight; then crushed and ground, passed through a 150-mesh sieve (pore size 106 μm), and the undersize was used as an adsorbent. The results of the measurement are shown in Table 1 and attached figure 2 shown.

[0030] Table 1

[0031]

[0032] Four kinds of adsorbents were prepared (the mo...

Embodiment 2

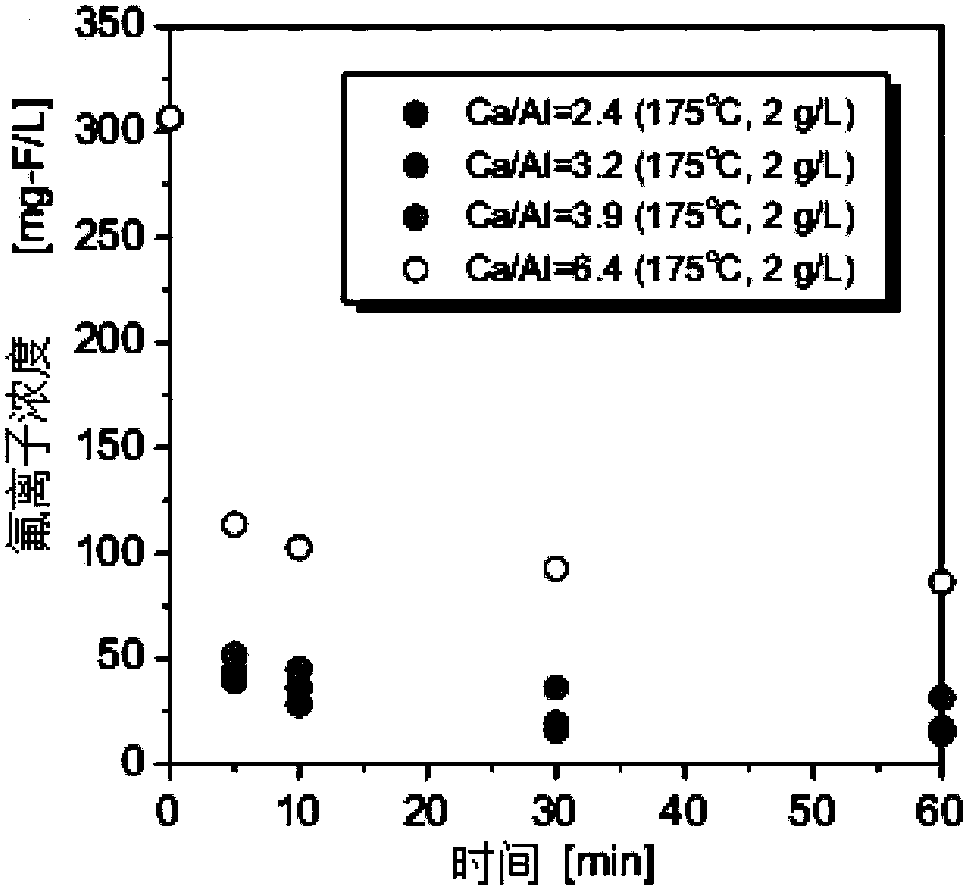

[0034] In parts by mass, mix 1 part of ordinary Portland cement with 3 parts of water and stir for 1 hour to prepare cement slurry; then add a pre-calculated amount of aluminum sulfate solid (85% by mass) into the cement slurry to make The calcium-aluminum molar ratios are 2.4, 3.2, 3.9, 6.4 respectively (the aluminum content in the cement raw materials is considered in the calculation); the colloidal solid obtained after stirring the cement slurry in a water bath at a constant temperature of 25°C for 24 hours uses nitrocellulose with a pore size of 8.0 μm The filter membrane was subjected to suction filtration; the filter cake was dried in an oven set at 40°C for 24h to constant weight; the obtained dry matter was baked at 175°C for 16h; then crushed and ground, and passed through a 150-mesh (pore size: 106μm) sieve , take the undersize as the adsorbent. Four kinds of adsorbents were prepared (the molar ratios of calcium to aluminum were 2.4, 3.2, 3.9, 6.4, respectively).

...

Embodiment 3

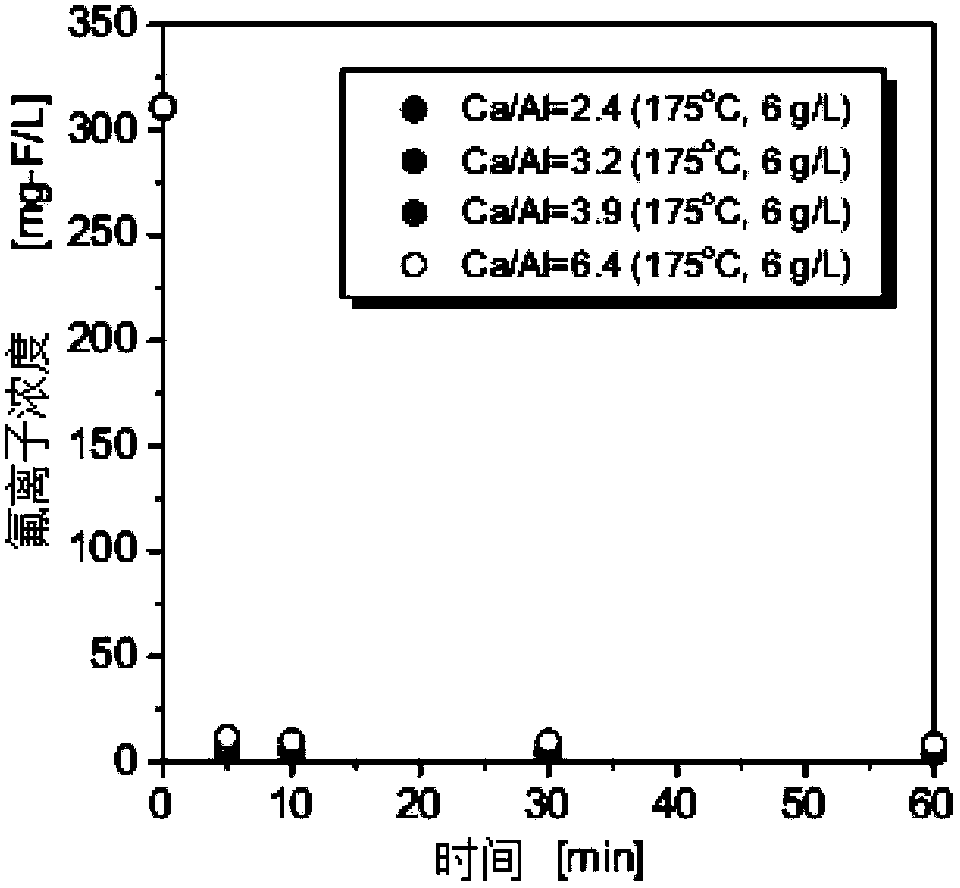

[0040] In parts by mass, mix 1 part of ordinary Portland cement with 3 parts of water and stir for 1 hour to prepare cement slurry; then add a pre-calculated amount of aluminum sulfate solid (85% by mass) into the cement slurry to make The calcium-aluminum molar ratios are 2.4, 3.2, 3.9, 6.4 respectively (the aluminum content in the cement raw materials is considered in the calculation); the colloidal solid obtained after stirring the cement slurry in a water bath at a constant temperature of 25°C for 24 hours uses nitrocellulose with a pore size of 8.0 μm The filter membrane was subjected to suction filtration; the filter cake was dried in an oven set at 40°C for 24h to constant weight; the obtained dry matter was baked at 175°C for 16h; then crushed and ground, and passed through a 150-mesh (pore size: 106μm) sieve , take the undersize as the adsorbent. Four kinds of adsorbents were prepared (the molar ratios of calcium to aluminum were 2.4, 3.2, 3.9, 6.4, respectively).

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com