Prestressed laminated wood with creep resistant deformation performance, and preparation method and use thereof

A technology of deformation performance and glued wood, which is applied in the direction of wood layered products, wooden veneer joints, chemical instruments and methods, etc., to achieve the effect of not changing the cost of materials, small volume, and improving structural performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

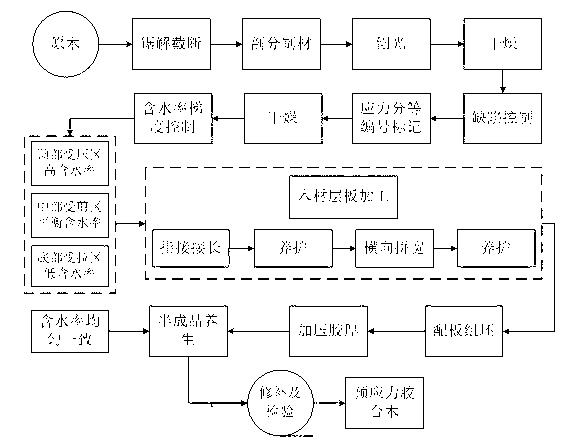

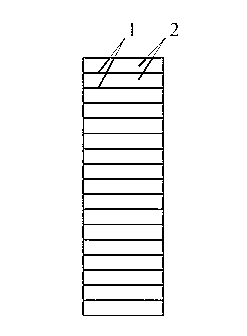

[0040] Such as figure 1 It is a preparation method of prestressed glulam with creep deformation resistance, and its steps are:

[0041] (1) Wood raw material pretreatment :According to the design requirements, Douglas fir and fast-growing poplar wood are cut, split, and planed through mechanical sawing to produce specifications with a thickness of 20mm, a width of 80mm, and a length of 1000mm. Dry the size lumber to control its moisture content within 15%, and eliminate and control the inherent natural defects, decay, knots, diagonal lines, cracks, wormholes and holes of Douglas fir and fast-growing poplar wood materials, and To carry out stress classification (stress classification number mark), the stress classification generally adopts mechanical elastic modulus and mechanical stress classification. The mechanical elastic modulus grading laminate is divided into 9 grades, and the average elastic modulus performance index of each grade is shown in Table 1. The stress grading...

Embodiment 2

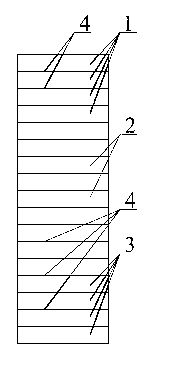

[0052] (1) Wood raw material pretreatment :According to the design requirements, through mechanical sawing and other processing methods, the specification lumber with a thickness of 45mm, a width of 280mm and a length of 6000mm is produced, and the specification lumber is dried to control its moisture content within the range of 25%. Natural defects, decay, knots, diagonal lines, cracks, worm holes and holes are removed and controlled. Then through stress grading and artificial drying, the moisture content of Douglas pine wood in the tension zone and compression zone of the high stress level is adjusted to 8% and 15%, respectively, and the moisture content of the masson pine wood in the low-grade shear zone is adjusted to 12%;

[0053] (2) Production of glulam laminate : Finger-joining, curing, horizontally widening and curing the wood of the same layer with the same moisture content. Finger-joining, widening and two curing processes are all operated under constant environmental...

Embodiment 3

[0058] (1) Wood raw material pretreatment :According to the design requirements, through mechanical sawing and other processing methods, the specification lumber with a thickness of 35mm, a width of 140mm and a length of 3000mm is produced, and the specification lumber is dried to control its moisture content within the range of 20%. Defects such as decay, knots, diagonal lines, cracks and wormholes should be controlled, and should be classified and numbered. Then by artificial drying, the moisture content of Douglas pine wood in the tension zone and compression zone is adjusted to 6% and 16% respectively, and the moisture content of masson pine wood in the shear zone is adjusted to 11%;

[0059] (2) Production of glulam laminate : Finger-joining, curing, horizontally widening and curing the wood of the same layer with the same moisture content. Finger-joining, widening and two curing procedures are all operated in an environmental condition that maintains a constant moisture co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com