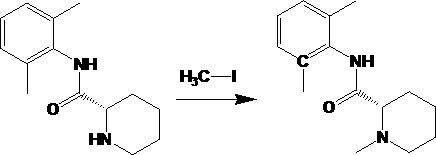

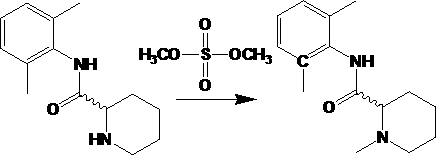

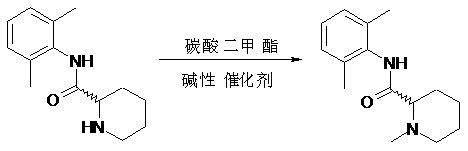

Preparation method of mepivacaine and optical enantiomer of mepivacaine

A technology of mepivacaine and enantiomers, applied in the field of reaction to obtain mepivacaine or its optical enantiomers, can solve the problems of quaternary ammonium salt by-products, expensive methyl iodide reagents, and high manufacturing costs, and achieve production The effect of low cost, simple operation, and few reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 46.5 g (0.2 mol) of N-(2,6-dimethylphenyl)-2-piperidine carboxamide and 200 ml of methanol into a 1-liter reaction flask, and control the temperature at 20 ℃ to 25 ℃ to stir and dissolve. Within 10 minutes, add 100ml of 10% sodium hydroxide solution (0.25mol) dropwise and heat to 40 ℃ ~ 45 ℃, add 19.8g (0.22mol) dimethyl carbonate dropwise, and keep the reaction for 4 hours after the dropwise addition. Within hours, the temperature was raised to 65°C, and the reaction was refluxed for 3 hours. Stop the reaction, lower the temperature to 0°C~5°C, add 60ml of concentrated hydrochloric acid, evaporate the solvent under reduced pressure at 40°C, add 100ml of water to dissolve the residue, adjust the pH to 13 with 10% sodium hydroxide at 0°C~5°C, filter , dried in vacuum at 40°C to obtain 47.2 g of mepivacaine. Yield 96.0%. mp 149°C–151°C, MS (EI) C 15 h 22 N 2 O m / z (M +. ): 246.1.

Embodiment 2

[0027] Add 46.5 g (0.2 mol) of N-(2,6-dimethylphenyl)-2-piperidine carboxamide and 200 ml of ethanol to a 1-liter reaction flask, and control the temperature at 20 ℃ to 25 ℃ to stir and dissolve. Within 10 minutes, add 165ml of 10% potassium carbonate solution (0.12mol) dropwise and heat to 40 ℃ ~ 45 ℃, add 19.8g (0.22mol) of dimethyl carbonate dropwise, after the dropwise addition, keep warm for 4 hours, then in 1 hour The temperature was raised to 80°C, and the reaction was refluxed for 5 hours. Stop the reaction, lower the temperature to 0 ℃ ~ 5 ℃, add 60ml of concentrated hydrochloric acid, evaporate the solvent under reduced pressure at 40 ℃, add 100ml of water to dissolve the residue, adjust the pH to 13 with 10% sodium hydroxide at 0 ℃ ~ 5 ℃, filter , and vacuum-dried at 40°C to obtain 35.2 g of mepivacaine. Yield 71.4%.

Embodiment 3

[0029] Add 46.5 g (0.2 mol) of N-(2,6-dimethylphenyl)-2-piperidine carboxamide and 200 ml of ethanol to a 1-liter reaction flask, and stir to dissolve at 20 ℃ to 25 ℃, about Within 10 minutes, add 140ml of 10% potassium hydroxide solution (0.25mol) dropwise and heat to 40 ℃ ~ 45 ℃, add 19.8g (0.22mol) dimethyl carbonate dropwise, and keep the reaction for 4 hours after the dropwise addition. Within hours, the temperature was raised to 80°C, and the reaction was refluxed for 5 hours. Stop the reaction, lower the temperature to 0 ℃ ~ 5 ℃, add 60ml of concentrated hydrochloric acid, evaporate the solvent under reduced pressure at 40 ℃, add 100ml of water to dissolve the residue, adjust the pH to 13 with 10% sodium hydroxide at 0 ℃ ~ 5 ℃, filter , and vacuum-dried at 40°C to obtain 45.5 g of mepivacaine. Yield 92.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com