Preparation method for extracting antibacterial peptides from wood frog bodies by using ultrasonic waves

An antimicrobial peptide and ultrasonic technology, which is applied in the field of production and preparation of antimicrobial peptides extracted from Rana body by ultrasonic waves, can solve the problems of antibacterial peptide filtrate not ideal antibacterial effect, difficulty in peeling Rana skin, loss and waste, etc., to save raw materials , Eliminate cumbersome procedures and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

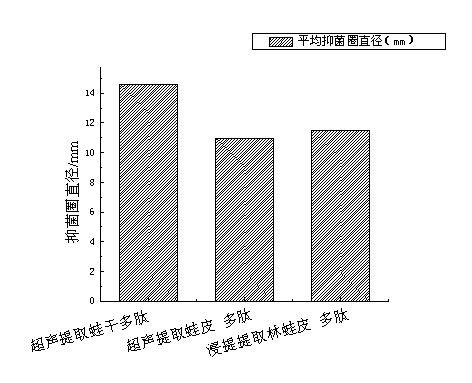

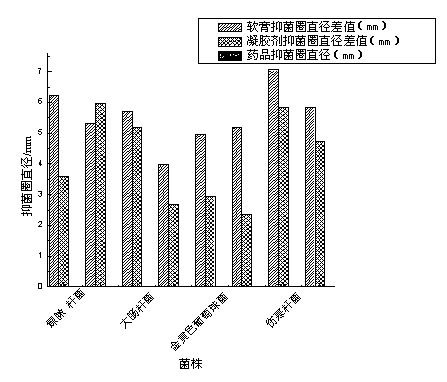

[0052] A production and preparation method for directly extracting antimicrobial peptides from wood frogs by ultrasonic waves:

[0053] 1. Take 50 g of the dry body of the degreased and de-egged wood frog, and carry out the dedusting and impurity removal treatment.

[0054] 2. Add 500 mL of 5% acetic acid 10 times that of the frog body and swell at 10°C for 0.2 hours.

[0055] 3. Put the swollen frog body and 5% acetic acid solution 10 times larger than the frog body together into an ultrasonic wave with a power of 100W and a frequency of 20kHz for 15 minutes. Under the same conditions as in 2 and 3, extract 1 more time.

[0056] 4. Combine the extracts, centrifuge at 3000p.r.m. for 20min, discard the precipitate, collect the supernatant, and follow steps 3 and 4 for one more operation.

[0057] 5. Combine the supernatants, heat at 50°C for 5 minutes, then lower to 10°C and filter.

[0058] 6. Concentrate to 1 / 3 volume at -0.5 atmospheric pressure at 35°C.

[0059] 7. Coll...

Embodiment 2

[0061] A production and preparation method for directly extracting antimicrobial peptides from wood frogs by ultrasonic waves:

[0062] 1. Take 50g of the dry body of the forest frog, and carry out dust and impurity removal treatment.

[0063] 2. Add 750 mL of 6% acetic acid 15 times that of the frog body and swell at 15°C for 0.3 hours.

[0064] 3. Put the swollen frog body into an ultrasonic wave with a power of 150W and a frequency of 30kHz for 10 minutes. Under the same conditions as in 2 and 3, extract 1 more time.

[0065] 4. Combine the extracts, centrifuge at 5000p.r.m, 15min, discard the precipitate, collect the supernatant, and repeat steps 3 and 4 twice.

[0066] 5. Merge the supernatant, and in 5 5 After heating at ℃ for 10 minutes, reduce to 10℃ and filter.

[0067] 6. Concentrate to 1 / 5 volume at -0.5 atmospheric pressure at 45°C.

[0068] 7. Collect the concentrated solution and store it at 4°C.

Embodiment 3

[0070] A production and preparation method for directly extracting antimicrobial peptides from wood frogs by ultrasonic waves:

[0071] 1. Take 50g of the dry body of the forest frog, and carry out dust and impurity removal treatment.

[0072] 2. Add 1000 mL of 7% acetic acid 20 times that of the frog body and swell at 20°C for 0.5 hours.

[0073] 3. Put the swollen frog body into an ultrasonic wave with a power of 200W and a frequency of 40kHz for 15 minutes. Under the same conditions as in 2 and 3, extract 1 more time.

[0074] 4. Combine the extracts, centrifuge at 5000p.r.m, 10min, discard the precipitate, collect the supernatant, and repeat steps 3 and 4 once.

[0075] 5. Combine the supernatants, heat at 60°C for 15 minutes, then reduce to 10°C and filter.

[0076] 6. Concentrate to 1 / 6 volume at -0.5 atmospheric pressure at 55°C.

[0077] 7. Collect the concentrated solution and store it at 4°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com