Phosphorus, nitrogen and bromine compound system fire retardant and preparation method thereof

A flame retardant and system technology, applied in the field of functional polymer materials, can solve the problems of application scope and production cost defects, and achieve the effects of low production cost, simple preparation process and good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

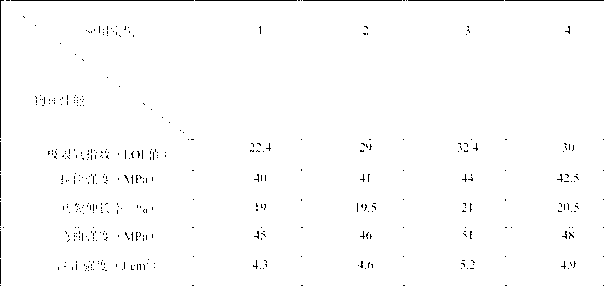

Examples

Embodiment 1

[0019] A phosphorus-nitrogen-bromine composite system flame retardant, which is prepared from the following raw materials in the weight ratio: MHB (melamine hydrobromide) 50g, APP (ammonium polyphosphate) 55g, flame retardant synergist Lianquat 4.5 g.

[0020] In the present embodiment, the bromine content in melamine hydrobromide is 35%, and the nitrogen content is 43%, which belongs to fine white powder, Nantong Yite Chemical Co., Ltd.; the phosphorus content in ammonium polyphosphate is 31%, and the nitrogen content is 15%, which belongs to fine white powder , Shenzhen Hongtaiji Industrial Co., Ltd.; Lianku is a liquid with a purity greater than 95wt%, Shanghai Maierui Chemical Technology Co., Ltd., and the above contents are all percentages by mass.

[0021] The preparation method of the above-mentioned phosphorus-nitrogen-bromine composite system flame retardant:

[0022] 1) Prepare the raw materials in the following weight proportions: 50g of MHB (melamine hydrobrom...

Embodiment 2

[0025] A phosphorus-nitrogen-bromine composite system flame retardant, which is prepared from the following raw materials in the weight ratio: MHB (melamine hydrobromide) 55g, APP (ammonium polyphosphate) 60g, flame retardant synergist Liancum 5g .

[0026] In the present embodiment, the bromine content in melamine hydrobromide is 35%, and the nitrogen content is 43%, which belongs to fine white powder, Nantong Yite Chemical Co., Ltd.; the phosphorus content in ammonium polyphosphate is 31%, and the nitrogen content is 15%, which belongs to fine white powder , Shenzhen Hongtaiji Industrial Co., Ltd.; Lianku is a liquid with a purity greater than 95wt%, Shanghai Maierui Chemical Technology Co., Ltd., and the above contents are all percentages by mass.

[0027] The preparation method of the phosphorus-nitrogen-bromine composite system flame retardant:

[0028] 1) Prepare the raw materials with the following weight ratio: MHB (melamine hydrobromide) 55g, APP (ammonium polyp...

Embodiment 3

[0031] A phosphorus-nitrogen-bromine composite system flame retardant, which is prepared from the following raw materials in the weight ratio: MHB (melamine hydrobromide) 60g, APP (ammonium polyphosphate) 65g, flame retardant synergist Lianquat 5.5 g.

[0032] Bromine content 35% in the melamine hydrobromide in this embodiment, nitrogen content 43% belong to fine white powder, Nantong Yite Chemical Co., Ltd.; Phosphorus content 31% in ammonium polyphosphate, nitrogen content 15% belong to fine white powder, Shenzhen City Hongtaiji Industrial Co., Ltd.; Lianku is a liquid with a purity greater than 95wt%, Shanghai Maierui Chemical Technology Co., Ltd.

[0033] A preparation method of a phosphorus-nitrogen-bromine composite system flame retardant:

[0034] 1) Prepare the raw materials with the following weight ratio: MHB (melamine hydrobromide) 60g, APP (ammonium polyphosphate) 65g, flame retardant synergist 5.5g;

[0035] 2) Put melamine hydrobromide (MHB) and amm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com