Vanadium dioxide composite powder and preparation method thereof

A technology of vanadium dioxide and composite powder, which is applied in the direction of vanadium oxide, chemical instruments and methods, vanadium compounds, etc., can solve the problems of destroying the structure of vanadium dioxide, and no modification method is proposed, so as to achieve the innovation of preparation process and the improvement of chemical Stability and dispersibility, effect of changing surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Take the mass of each component as follows:

[0054] Vanadium dioxide nanopowder (doped with tungsten, particle size 20-100nm), 20g

[0055] Ethanol (dispersion medium), 80g

[0056] Silane coupling agent (containing polyvinyl alcohol group, organic modifier), 1g

[0057] Polyvinylpyrrolidone (dispersion aid), 0.05g;

[0058] Firstly, vanadium dioxide nanopowder and dispersion medium were stirred and dispersed at a high speed of 1500rad / min for 30 minutes, and ultrasonically dispersed for 30 minutes, then the dispersion aid and silane coupling agent were added to it, and stirred at a constant temperature of 70°C on a high-speed mixer for 2 hours , then centrifuged and precipitated, and vacuum dried at 60°C to obtain a vanadium dioxide composite powder modified by an organosilicon coupling agent;

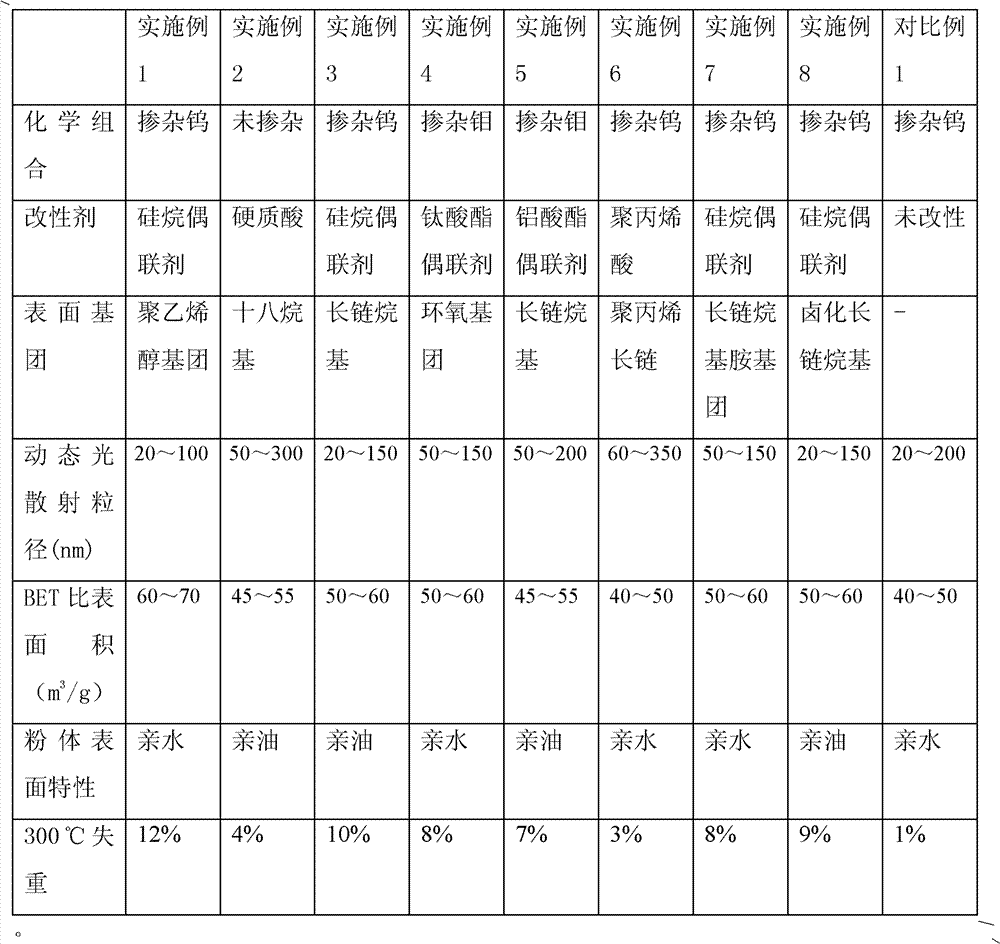

[0059] The main properties of the obtained vanadium dioxide and its doped composite powder are shown in Table 1.

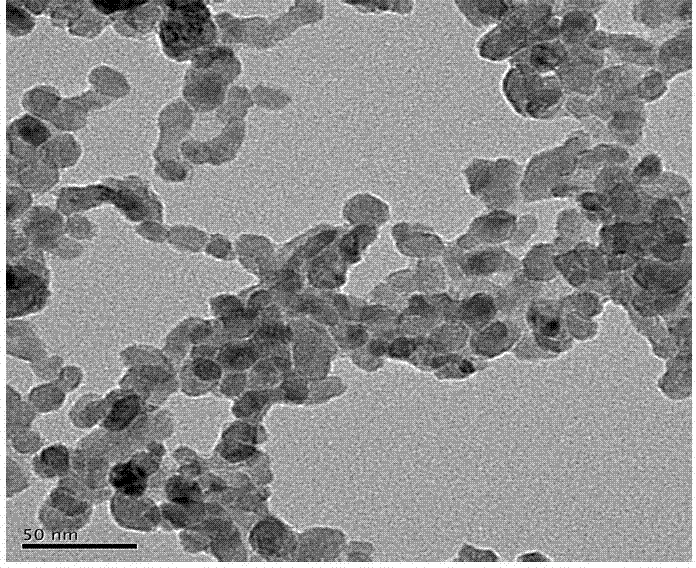

[0060] Such as figure 2 As shown, the morphology of th...

Embodiment 2

[0062] Take the mass of each component as follows:

[0063] Vanadium dioxide nanopowder (without doping, particle size 20-60nm), 10g

[0064] Ethanol (dispersion medium), 90g

[0065] Stearic acid, 1g

[0066] Polyvinyl alcohol (dispersion aid), 0.05g

[0067] First, the vanadium dioxide nanopowder and dispersion medium were stirred and dispersed at a high speed of 1500rad / min for 30 minutes, and ultrasonically dispersed for 30 minutes, then the dispersion aid and stearic acid were added, and stirred at a constant temperature of 60°C on a high-speed mixer for 2 hours. Centrifuge again, dry under vacuum at 60°C to obtain stearic acid-modified vanadium dioxide nanocomposite powder;

[0068] The main properties of the obtained vanadium dioxide and its doped composite powder are shown in Table 1.

Embodiment 3

[0070] Take the mass of each component as follows:

[0071] Vanadium dioxide nanopowder (doped with tungsten, particle size 20-100nm), 15g

[0072] Isopropanol (dispersion medium), 85g

[0073] Silane coupling agent (containing long chain alkyl, organic modifier), 1g

[0074] Organomodified polysiloxane dipropylene glycol monomethyl ether solution (dispersion aid), 0.08g

[0075] First disperse the vanadium dioxide nano-powder and the dispersion medium at a high speed of 1000rad / min for 20 minutes, and ultrasonically disperse it for 60 minutes, then add the dispersion aid and silane coupling agent, and stir for 2 hours on a high-speed mixer at a constant temperature of 80°C , centrifuged and precipitated, vacuum dried at 60°C to obtain vanadium dioxide nanocomposite powder with long-chain alkyl attached to the surface;

[0076] The main properties of the obtained vanadium dioxide and its doped composite powder are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com