Additive for well cementing cement mortar, and preparation and application methods thereof

A cementing cement slurry and admixture technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as costing a lot of money, interlayer channeling, and high safety risks, so as to reduce permeability and improve The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

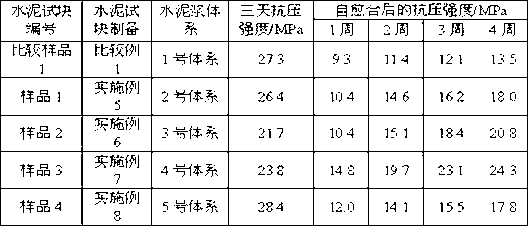

[0026] Take 60%wt modified phenolic resin, add calcium carbonate 20%wt, active silicon dioxide 15%wt, alkyl silane 5%wt, put it into a double-screw mixer, mix it, mix it repeatedly for 2 hours, and wait until it is uniform After that, the product is obtained, which is a white powder 1# product.

Embodiment 2

[0028] Take 55%wt modified phenolic resin, add 20%wt of calcium carbonate, 15%wt of active silicon dioxide, and 10%wt of alkylsilane, put it into a double-screw mixer, mix it, and mix it repeatedly for 2 hours, until it is uniform After that, the product is obtained, which is a white powder 2# product.

Embodiment 3

[0030] Take 50%wt modified phenolic resin, add calcium carbonate 20%wt, active silicon dioxide 20%wt, alkyl silane 10%wt, put it into a double-screw mixer, mix it, mix it repeatedly for 2 hours, and wait until it is uniform After that, the product is obtained, which is a white powder 3# product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com