Method for preparing fructo oligosaccharides by using sugarcane juices

A technology for fructooligosaccharides and sugarcane juice, which is applied in the conversion of immobilized fructosyltransferase columns, the preparation of fructooligosaccharides in the concentration process, and the decolorization field, can solve problems such as unfavorable continuous production, no relevant reports, complicated processes, etc. Avoid the participation of chemical reagents, shorten the process flow, and achieve the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

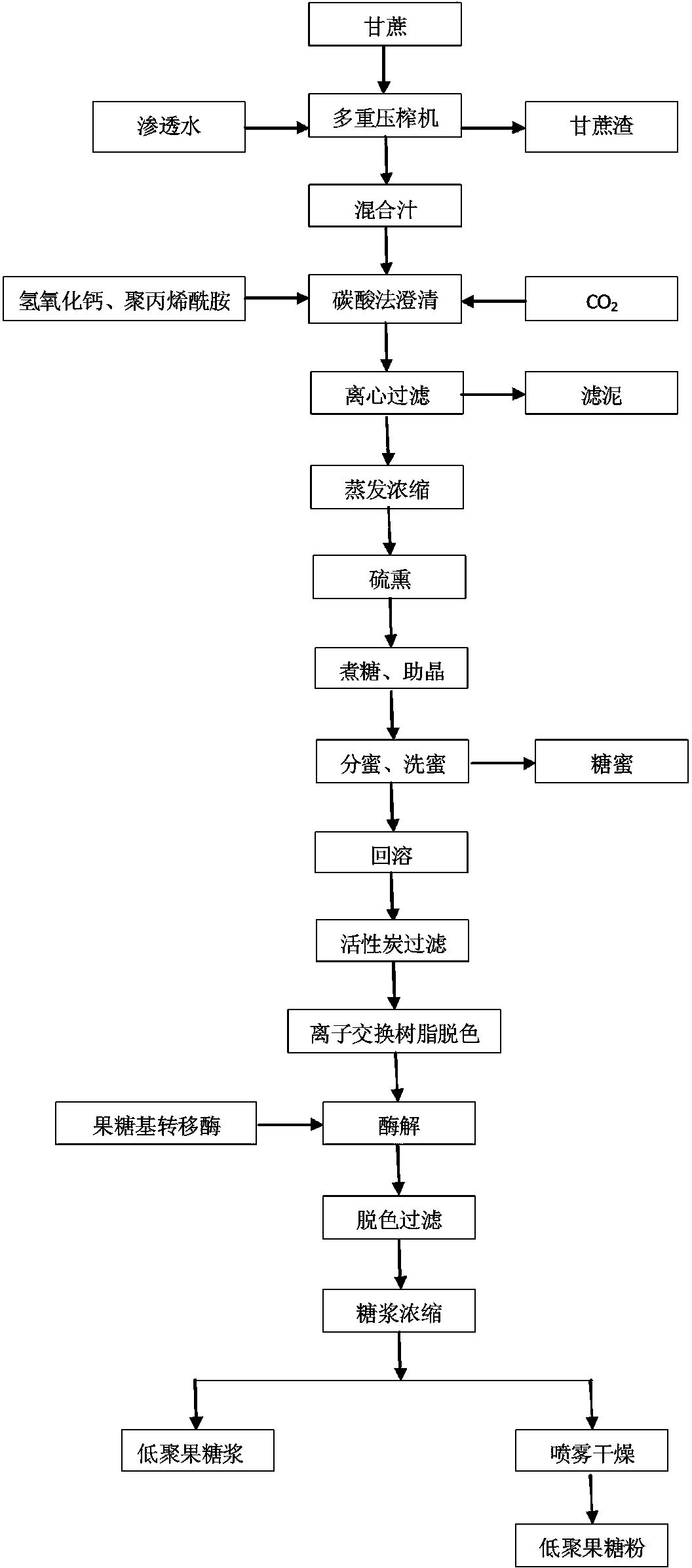

Image

Examples

Embodiment 1

[0042] Extraction of cane juice: The sugarcane is squeezed and extracted by multiple presses. The cane stalks are first chopped into pieces, or the cane is torn, and then the juice is extracted through a press. In order to help extract cane juice, a small amount of water is sprayed into bagasse and then squeezed to promote the leaching of sucrose, so as to maximize the use of raw materials to obtain sugarcane mixed juice.

[0043] Clarification of cane juice: The sugarcane juice is preliminarily treated with calcium hydroxide to make the pH of the solution = 11, and the temperature is adjusted to 45°C for about 5 minutes. After pre-ash treatment, continue to add calcium hydroxide to pH = 12.5, and release CO for the first time 2 Gas, neutralize to make the pH of the solution = 11, control the temperature at 50°C, and take 10 minutes to produce flocculent calcium carbonate. The precipitate was centrifuged once. Then release the CO for the second time 2 Gas, neutralize to ma...

Embodiment 2

[0056] Extraction of cane juice: The sugarcane is squeezed and extracted by multiple presses. The cane stalks are first chopped into pieces, or the cane is torn, and then the juice is extracted through a press. In order to help extract cane juice, a small amount of water is sprayed into bagasse and then squeezed to promote the leaching of sucrose, so as to maximize the use of raw materials to obtain sugarcane mixed juice.

[0057] Clarification of cane juice: The sugarcane juice is preliminarily treated with calcium hydroxide to make the pH of the solution = 11, and the temperature is adjusted to 55°C for about 5 minutes. After the pre-ash treatment, continue to add calcium hydroxide to pH = 13, and release CO for the first time 2 Gas, neutralize to make the pH of the solution = 11, control the temperature at 55°C, and take 14 minutes to produce flocculent calcium carbonate. The precipitate was centrifuged once. Then release the CO for the second time 2 Gas, neutralize to ...

Embodiment 3

[0070] Extraction of cane juice: The sugarcane is squeezed and extracted by multiple presses. The cane stalks are first chopped into pieces, or the cane is torn, and then the juice is extracted through a press. In order to help extract cane juice, a small amount of water is sprayed into bagasse and then squeezed to promote the leaching of sucrose, so as to maximize the use of raw materials to obtain sugarcane mixed juice.

[0071] Clarification of cane juice: The sugarcane juice is preliminarily treated with calcium hydroxide to make the solution pH = 11, and the temperature is adjusted to 50°C for about 8 minutes. After the pre-ash treatment, continue to add calcium hydroxide to pH = 13, and release CO for the first time 2 Gas, neutralize to make the pH of the solution = 11, control the temperature at 60°C, and take 15 minutes to produce flocculent calcium carbonate. The precipitate was centrifuged once. Then release the CO for the second time 2 Gas, neutralize to make th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com